Energy-saving solar full tracking power generation components

An energy-saving and component technology, applied in the direction of feedback control, etc., can solve the problems of increasing structural complexity, power consumption, and difficult maintenance, etc., and achieve the effects of easy control and maintenance, cost saving, and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is illustrated by taking a cement powder storage and transportation tanker as an example.

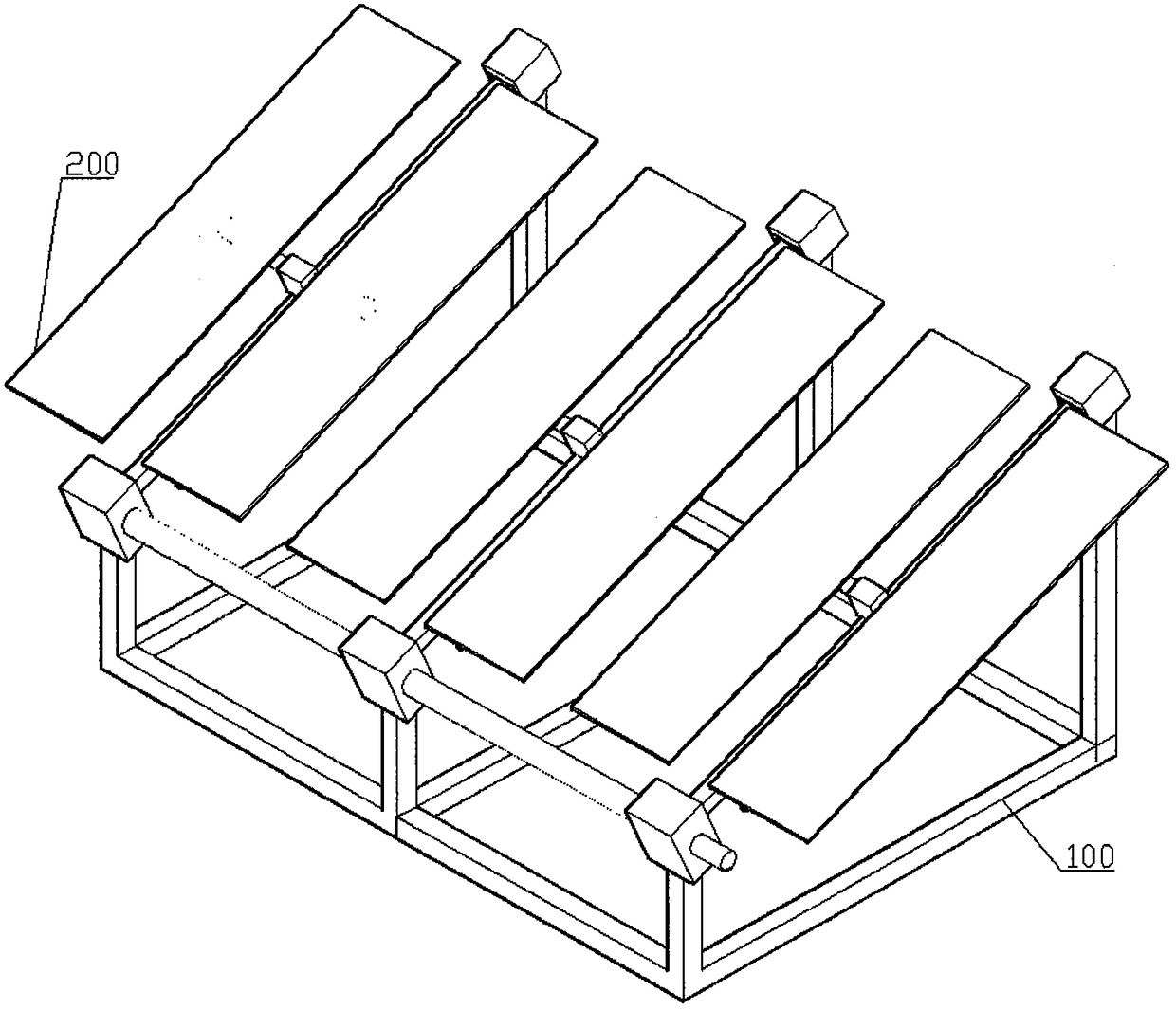

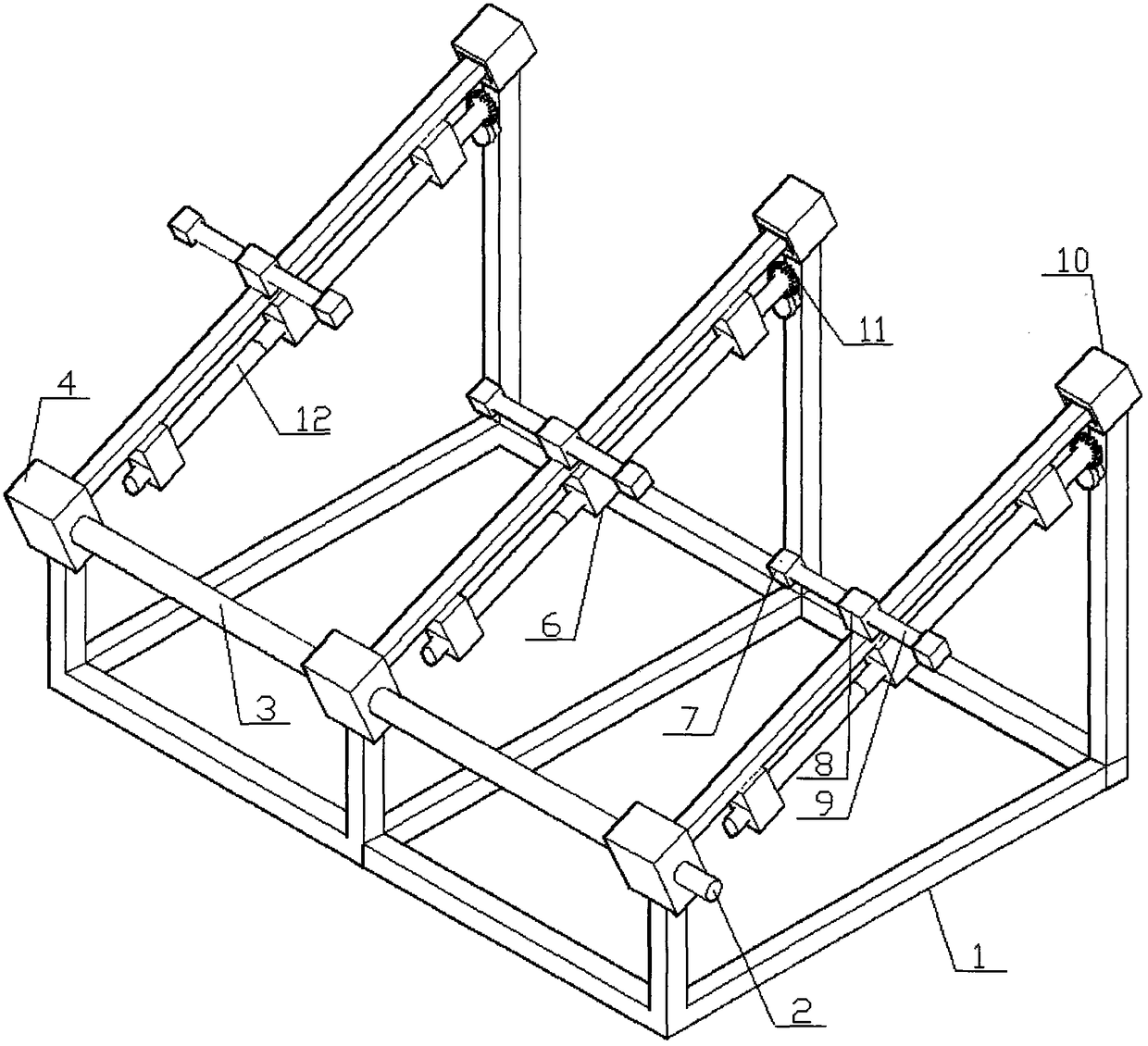

[0028] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the energy-saving solar full-tracking power generation module of the present invention is installed in a place where the geographic latitude is β, and includes a tracking frame 100 and a photovoltaic module 200 installed on the tracking frame 100;

[0029] The tracking frame 100 includes a support 1 on which at least two sets of tracking mechanisms with the same structure are arranged in parallel;

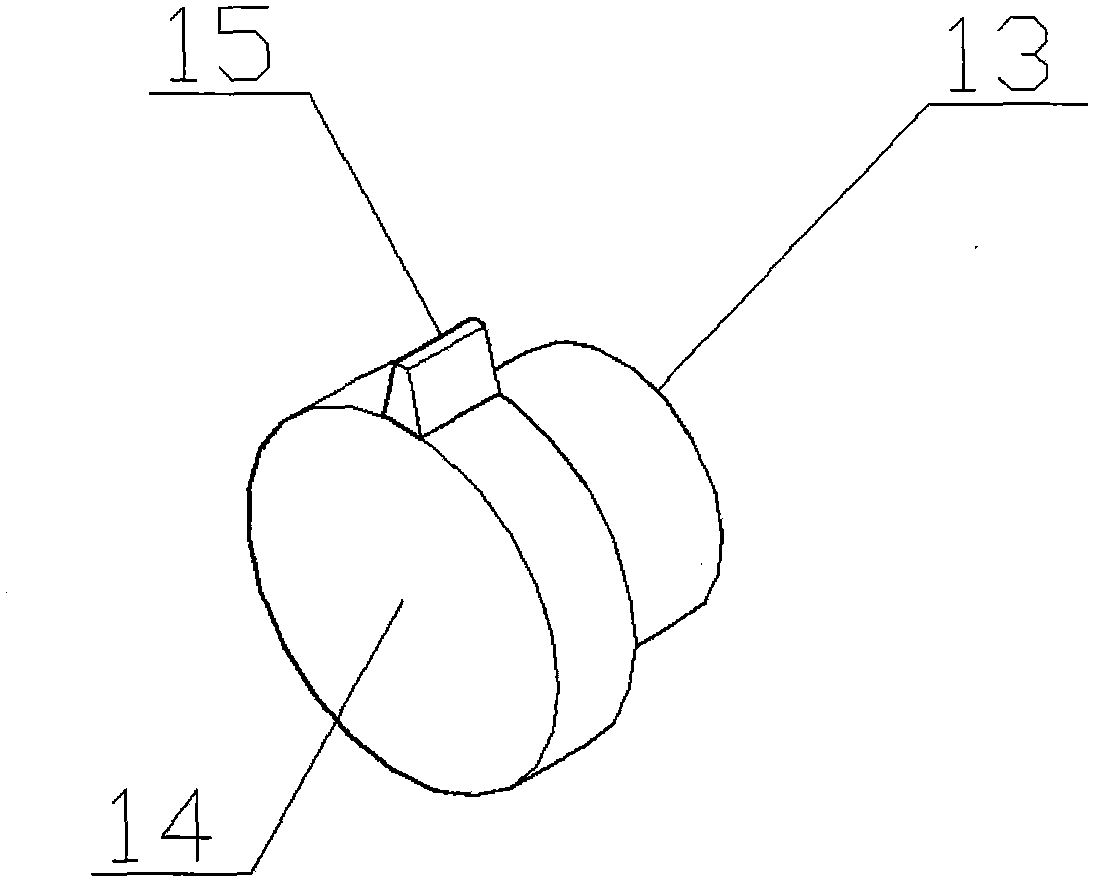

[0030] The tracking mechanism includes a polar axis rotating shaft with a β inclination angle relative to the ground. A horizontal declination axis 9 is installed on the polar axis rotating axis. A photovoltaic mounting bracket 7 is arranged on the declination axis 9 and photovoltaic mounting bracket 7 is installed on the polar axis. Assembly 200; the declination shaft 9 is installed on the polar a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com