Method for adding ink dot identification to MAP of prober

A MAP map and probe station technology, which is applied in the field of integrated circuit testing and manufacturing, can solve problems such as missing, and achieve the effect of improving equipment capacity and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

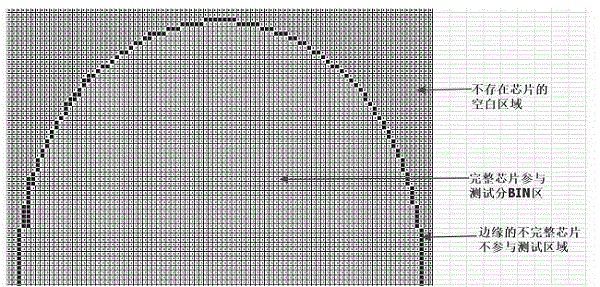

[0025] The present invention is used for the method for adding ink dots to the MAP map of the TSK UF series probe station, which comprises the following steps:

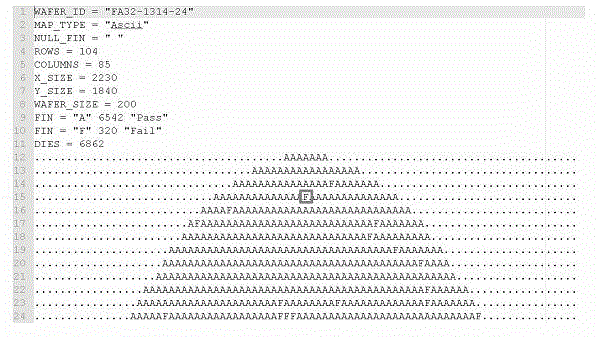

[0026] 1) Obtain the standard UF200 original image data that the wafer WAFER runs over the UF200 series probe station tester and call the MAP file.

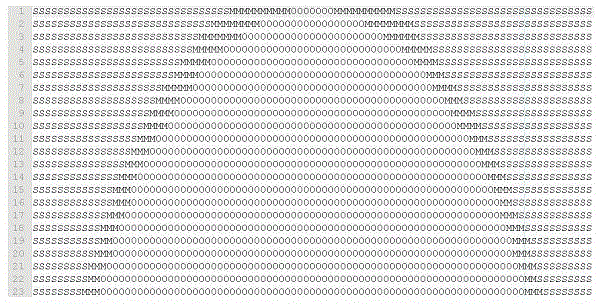

[0027] 2) Open the MAP file in hexadecimal mode, extract the header file and the coordinates and identifier parameters of each chip according to the data format and length set by the UF200 probe station, and output it to the asicc-coded "UF200.txt "template.

[0028] 3) Use the text method to open the unified format of the MAP file that needs to be dotted, and convert it into the standard asicc coded "OTHER.txt" MAP file.

[0029] 4) Read the "OTHER.txt" file of asicc code that needs to be dotted, extract the row and column parameters of each chip, combine its position information in the "UF200.txt" template, restore it, and output it to "ink_MAP.txt" document.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com