Noodle pressing machine with automatic noodle making function

A noodle press, automatic technology, applied in the field of noodle presses, can solve the problems of low kneading efficiency, low safety factor, low degree of automation, etc., and achieve the effect of high kneading efficiency and delicious taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

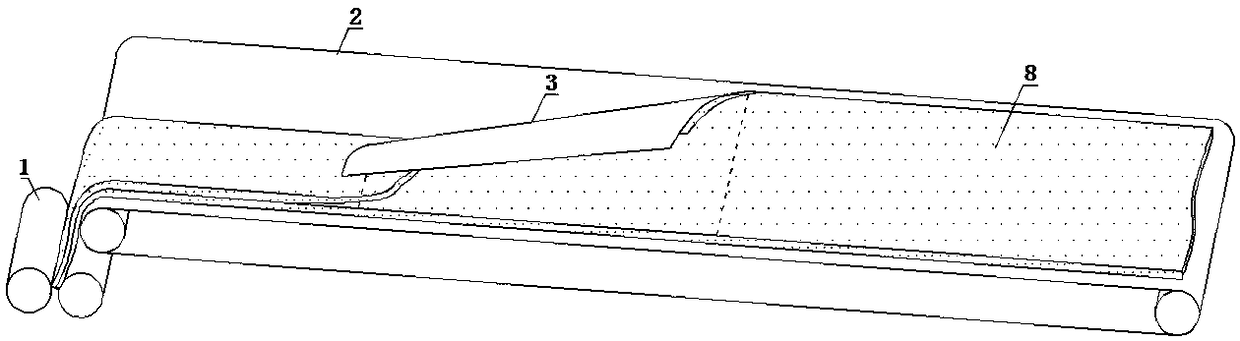

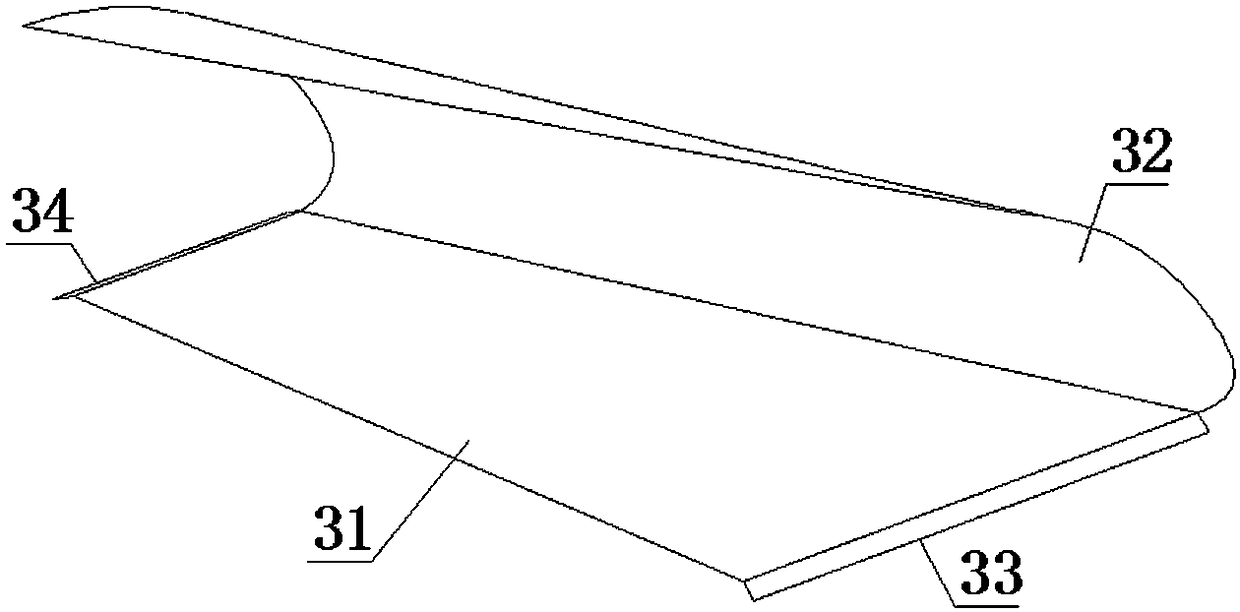

[0026] Such as figure 1 with figure 2 As shown, the conveying device is the main conveyor belt 2, and the automatic noodle arrangement device includes a turning panel 3 for turning over the dough 8 that is used in conjunction with the main conveyor belt 2, and the turning panel 3 is composed of a flat bottom Surface 31 and arc-shaped gradual change surface 32 are formed, and described flat bottom surface 31 is arranged on its upper surface parallel to main conveyer belt 3, and the end that described flat bottom surface 31 dough enters is front end, and the end that dough leaves is rear end, and described The arc-shaped transition surface 32 is arranged on one side of the flat bottom surface 31, and the arc-shaped transition surface 32 is gradually contracted from the front end to the rear end of the flat bottom surface 31, and the width of the front end of the flat bottom surface 31 is twice the width of the rear end.

[0027] During concrete setting, turning plate 3 is arra...

Embodiment 2

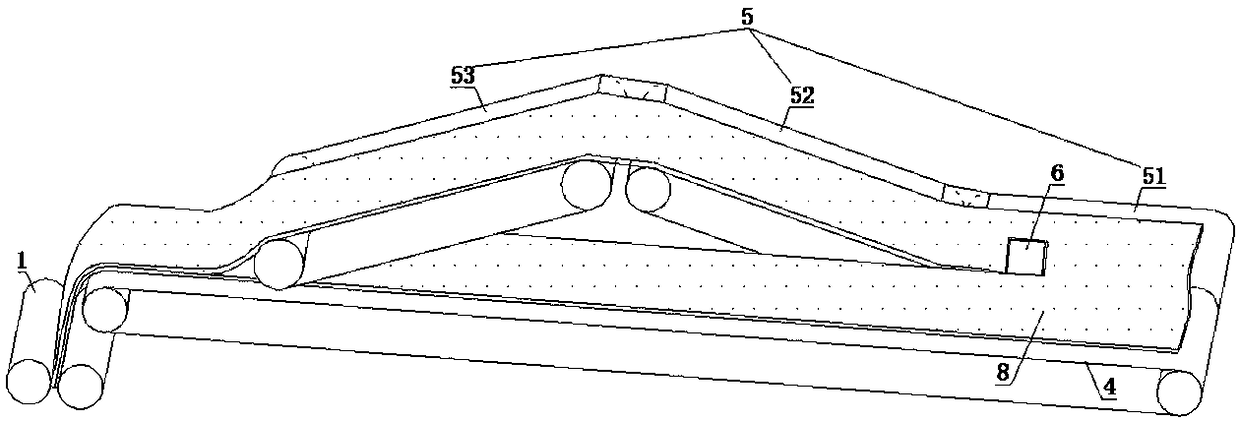

[0031] Such as image 3As shown, the automatic noodle arrangement device is a face-stacking device; the face-stacking device includes a first conveyor belt 4, a face-stacking conveyor belt group 5 and a faceting knife 6; the first conveying The belt 4 is arranged in a straight line; the stacked surface conveyor belt group 5 includes a second conveyor belt 51, an outgoing conveyor belt 52 and a return conveyor belt 53 arranged in sequence along the conveying direction, and the second conveyor belt 51 and the first The conveyor belts 4 are arranged side by side, the outgoing conveyor belt 52 is arranged obliquely upward, and its front end is adjacent to the end of the second conveyor belt 51, and the return conveyor belt 53 is arranged obliquely downward, and its front end is adjacent to the outgoing conveyor belt 52 , and the end of the return conveyor belt 53 is located directly above the first conveyor belt 4, that is, viewed from the top view, the outgoing conveyor belt 52 a...

Embodiment 3

[0035] Such as Figure 4 with Figure 5 As shown, the conveying device is the main conveyor belt 2, and the automatic noodle arrangement device is a rolling device that can roll the dough 8 into a column, and the rolling device includes a rolling roll 71, a pressing wheel 72 and The guide wheel set 73, the rolling surface roller 71 is obliquely arranged on the upper surface of the main conveyor belt 2, the pressure wheel 72 is arranged at the end of the rolling surface roller 71, and the guide wheel set 73 is arranged side by side in two rows Both sides of the pinch roller 72 ends.

[0036] During use, the dough 8 is placed on the main conveyor belt 2, and the main conveyor belt 2 sends the dough 8 to the rolling roller 71. Rolled into a strip, the strip-shaped surface is further compacted and rounded by the pressure roller 72 from the end of the rolling roller 71, and then after being guided by the guide wheel group 73, it continues to move parallel to the front of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com