Open mill for regenerated rubber processing

A technology of reclaimed rubber and open mill, which is applied in the field of reclaimed rubber processing equipment, can solve the problems of low processing efficiency, many operation labor, and large floor space, and achieves the effect of easy operation, reduced noise and small floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

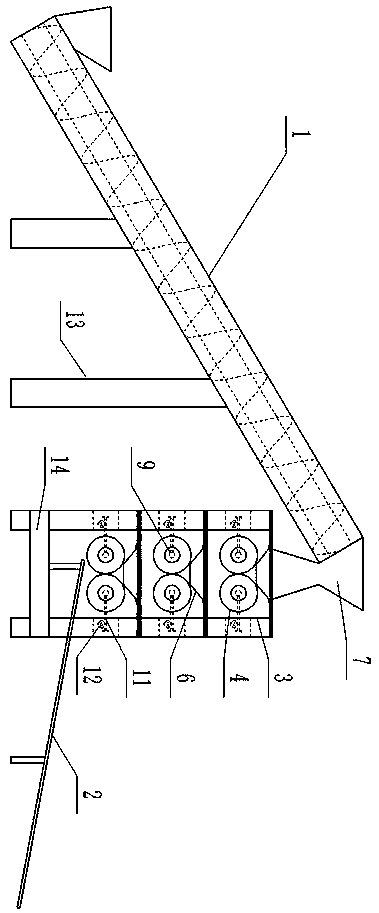

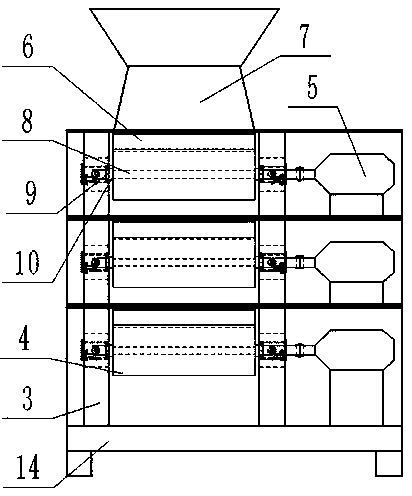

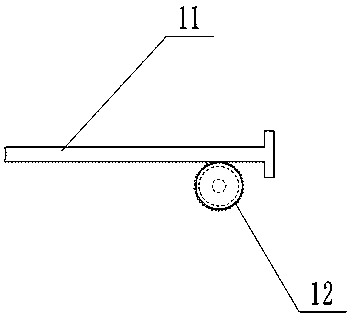

[0028] like Figure 1-3 As shown, an open mill for reclaimed rubber processing includes an open mill body, a feeding device 1 and a discharging device 2; the open mill body includes a frame 3, a roller 4, and a roller gap adjustment. device, speed regulating motor 5, silo 7 and feeding hopper 6, the rollers 4 include at least three groups, each group of rollers 4 is composed of two parallel rollers 4, and at least three groups of rollers 4 are from top to bottom. The lower part is arranged on the frame 3 in parallel, and the roller gaps of each group of rollers 4 are corresponding. The number of the speed regulating motor 5 matches the number of the rollers 4 , the speed regulating motor 5 is drivingly connected with the roller 4 , and the number of the feeding funnels 6 matches the number of groups of the rollers 4 Matching, the feeding funnel 6 is arranged above the roller gap of each group of rollers 4, the silo 7 is arranged on the top of the frame 3, the feeding port of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com