Tea leaf drying device with roller and using method of tea leaf drying device

A technology of a tea drying device and a drum, which is applied in the directions of tea drying, drying, drying machine, etc., can solve the problems of inability to standardize production to ensure the quality of tea leaves, cumbersome and other problems, and achieve the realization of mechanized production, simple device structure and high quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

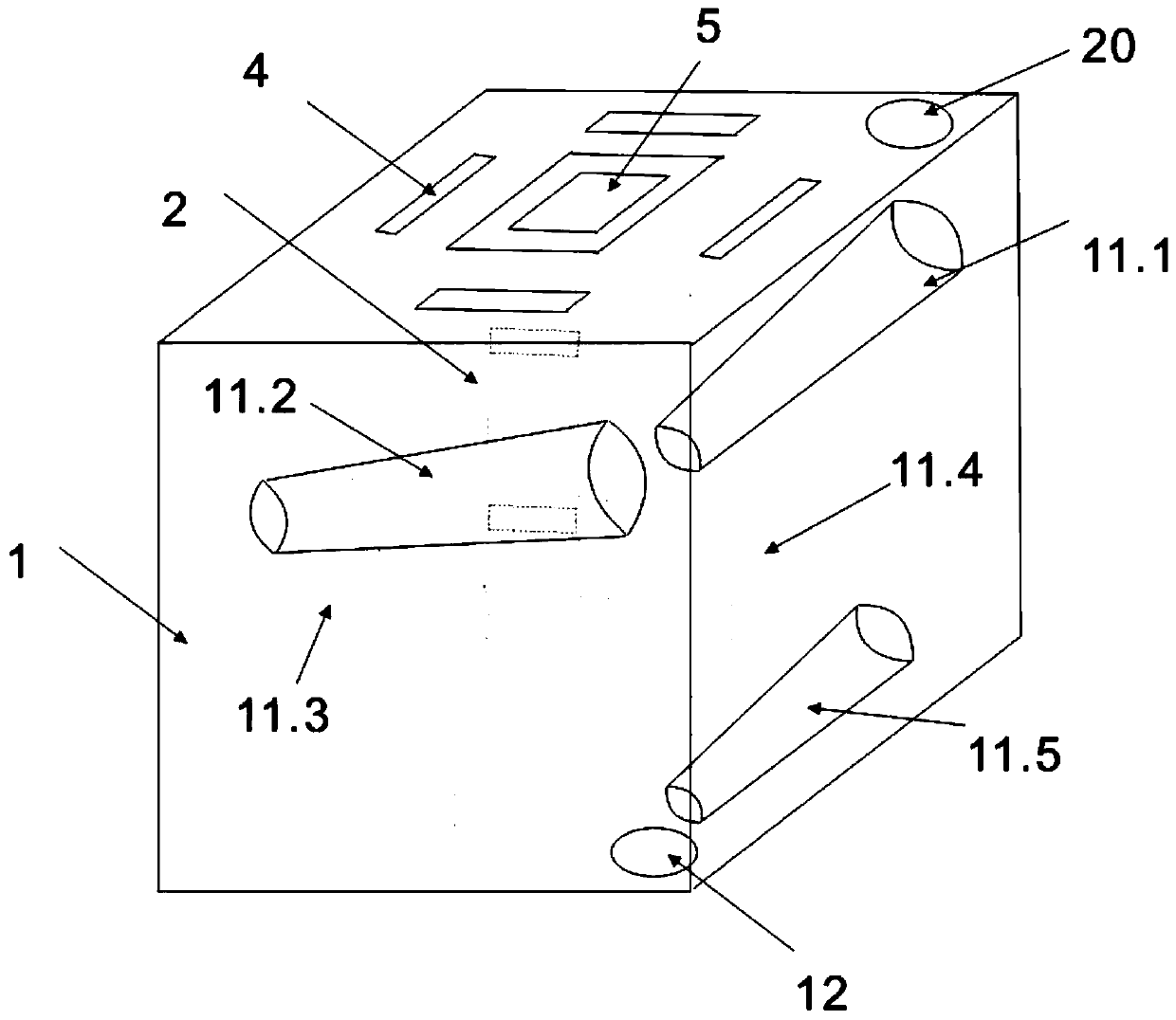

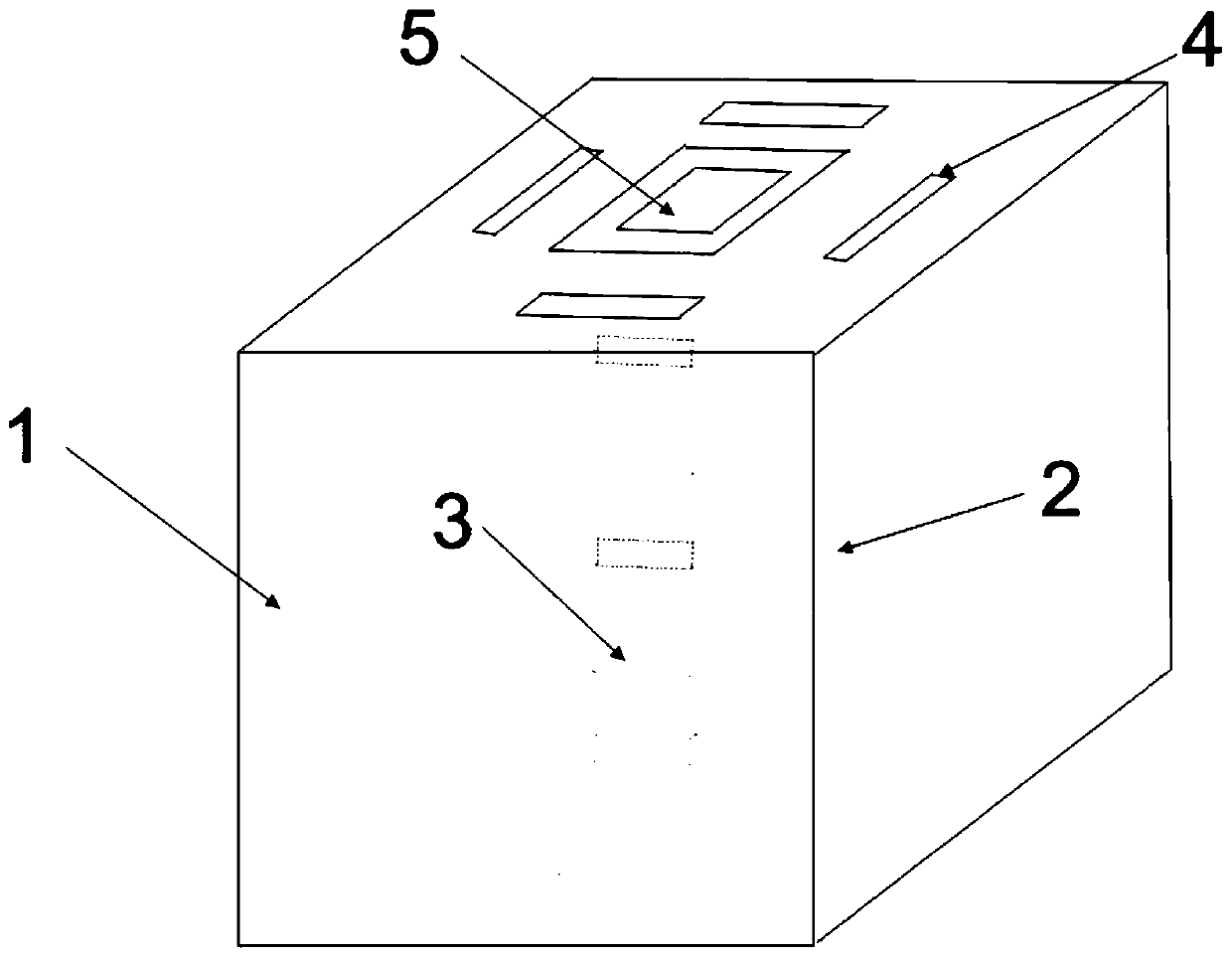

[0038] The drums of the tea drying device in this embodiment are arranged in a spiral shape around the hot air box. For details, refer to Figure 1~Figure 11 , figure 1 For the overall beauty of the picture, the conveyor belt is not drawn; Figure 5 is a perspective view of the bottom box of the hot air box, and the shaded part is a schematic diagram of the wall of the heat collecting tube. The device includes: outer box body 1, hot air box body 2, upper box body 2.1 of hot air box body, bottom box body 2.2 of hot air box body, hot air outlet 3, exhaust port 4, exhaust gas outlet 5, air inlet 6 , heating port 7, heat collecting pipe wall 8, fan 9, hot air inlet 10, drum 11, drum, tea outlet 12, connecting arm 13, motor 14, rotating shaft 15, drum bracket 16, conveyor belt 17, baffle 17.1 , Conveyor belt drive motor 17.2, transmission chain 17.3, fixed frame 18, bearing 19 and tea inlet 20; Described drum comprises first drum 11.1, second drum 11.2, third drum 11.3, fourth dr...

Embodiment 2

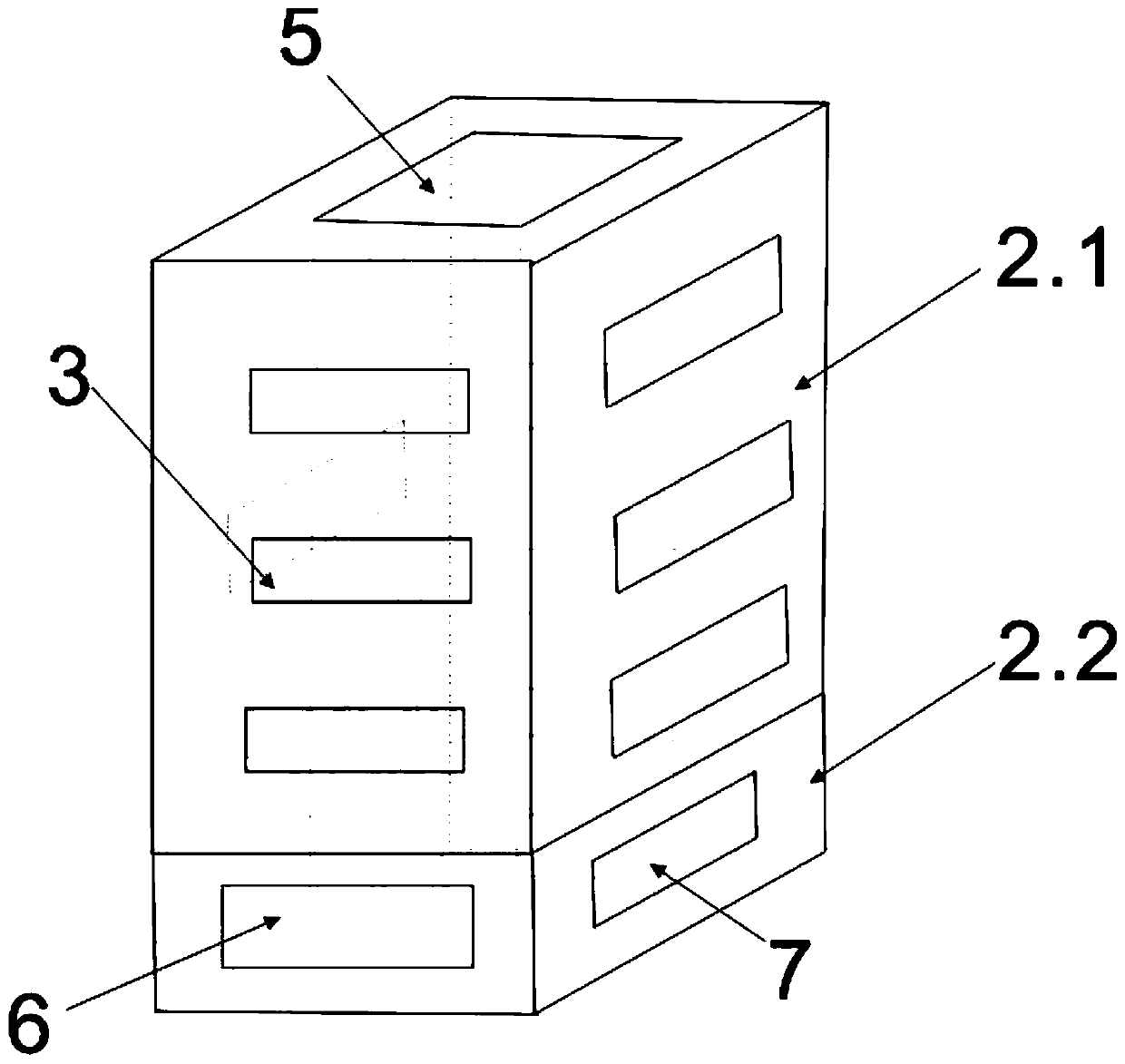

[0040] The rollers of the tea drying device in this embodiment are arranged in a turning shape arranged up and down on one side of the hot air box body 2. For details, refer to Figure 12 , refer to Example 1 for other partial schematic diagrams. The device includes: outer box body 1, hot air box body 2, upper box body 2.1 of hot air box body, bottom box body 2.2 of hot air box body, hot air outlet 3, exhaust port 4, exhaust gas outlet 5, air inlet 6 , heating port 7, heat collecting pipe wall 8, fan 9, hot air inlet 10, drum 11, drum, tea outlet 12, connecting arm 13, motor 14, rotating shaft 15, drum bracket 16, conveyor belt 17, baffle 17.1 , Conveyor belt drive motor 17.2, transmission chain 17.3, fixed frame 18, bearing 19 and tea inlet 20; Described drum comprises first drum 11.1, second drum 11.2, third drum 11.3 and fourth drum 11.4;

[0041] The hot-blast box 2 is located inside the outer box 1, and a hot-blast outlet 3 is provided on the side wall of the hot-blast b...

Embodiment 3

[0043] Adopt the device among the embodiment 1, test the water content of the tealeaves after the Langqing step treatment earlier, record its water content as 72%, adjust the angle between the cylinder and the horizontal plane to be 20 °, then turn on the equipment power switch, Make the internal drum, conveyor belt, fan and burner start. In this embodiment, the rotating speed of the drum is 5r / min; adjust the temperature of the hot air so that the hot air reaches the predetermined temperature of 125°C, and then put the semi-finished tea leaves to be processed into the tea inlet , to dry the tea leaves, the first drying time is 3 minutes, after the tea leaves come out completely from the outlet, turn off the power, adjust the angle between the roller and the horizontal plane to 40° again, turn on the power, and control the temperature of the hot air At 100°C, pour the tea from the tea inlet again and dry it for 2 minutes. At this time, the tea at the outlet has been tested and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com