Device and method for high-throughput preparation of arrayed bulk amorphous alloys

An amorphous alloy and preparation device technology, which is applied in the field of high-throughput preparation devices for arrayed bulk amorphous alloys, can solve problems such as high cost, inability to meet experimental research on bulk amorphous alloys, and low efficiency, and achieve heating Fast speed, good impurity removal effect, and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

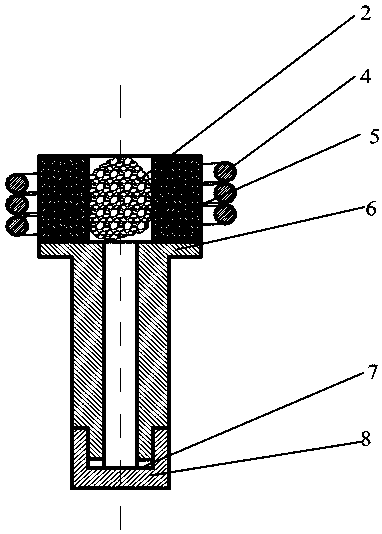

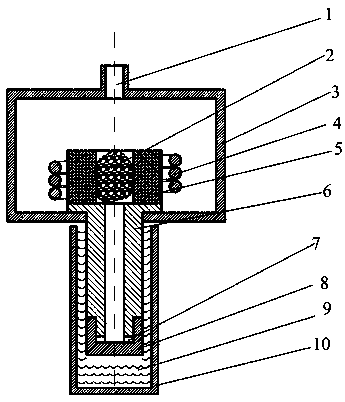

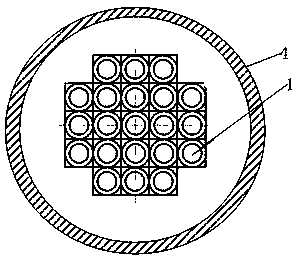

[0029] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0030] Such as Figures 1 to 4 As shown, the high-throughput preparation device of the arrayed bulk amorphous alloy of the present invention includes an intake and exhaust port 1, a vacuum high-pressure chamber 3, an electromagnetic induction coil 4, a crucible 5, a copper mold 6, a sealing gasket 7, and a copper mold bottom cover 8. Cooling water 9, water jacket 10, wherein:

[0031] Intake and exhaust ports, used to introduce high-purity argon;

[0032] The vacuum high pressure chamber is a cylindrical stainless steel container, which is connected and sealed with the copper mold, and is used to place the crucible and the electromagnetic induction coil;

[0033] Electromagnetic induction coil, heating and melting the alloy and purifying the melt;

[0034] Crucible, used to hold alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com