Full-automatic numerical control glasses frame processing machine

A processing machine, fully automatic technology, applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of low work efficiency and inability to carry out at the same time, so as to improve work efficiency, eliminate influence and reduce scrap rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

[0033] The following references Figure 1 to Figure 9 The present invention will be described.

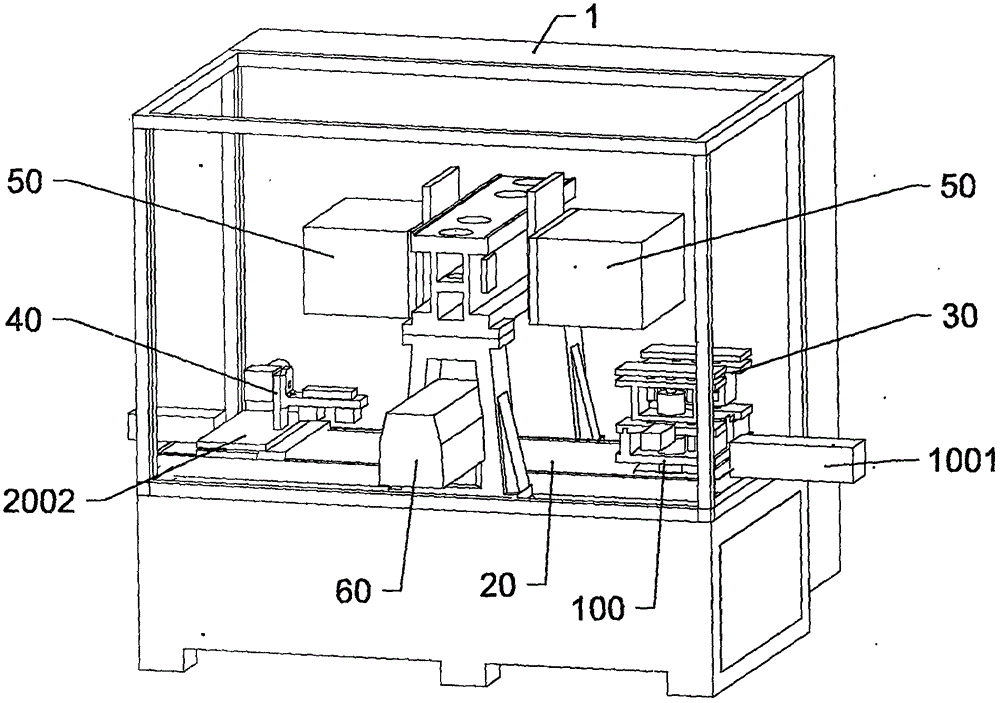

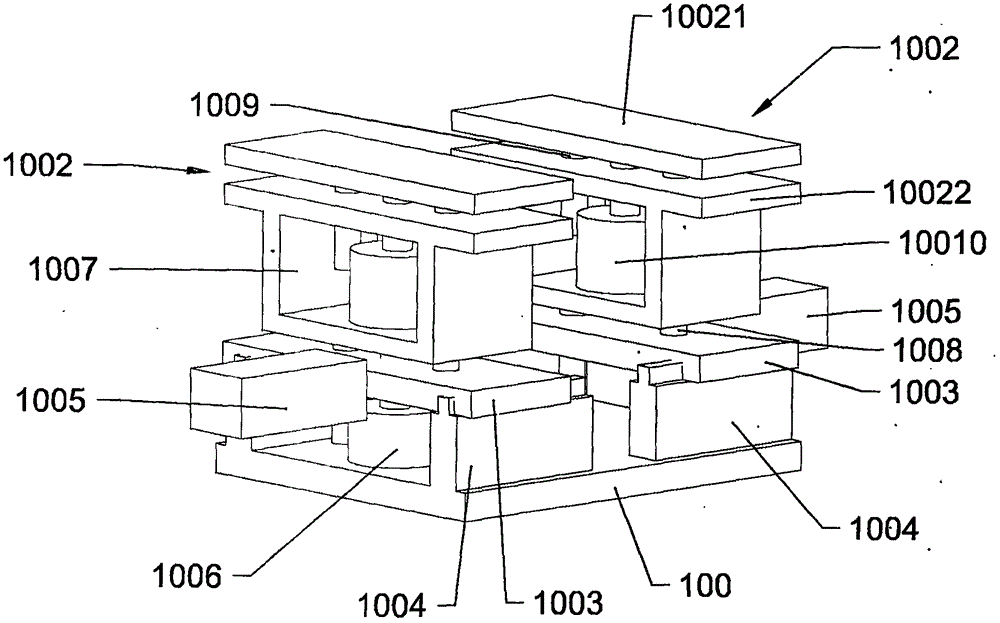

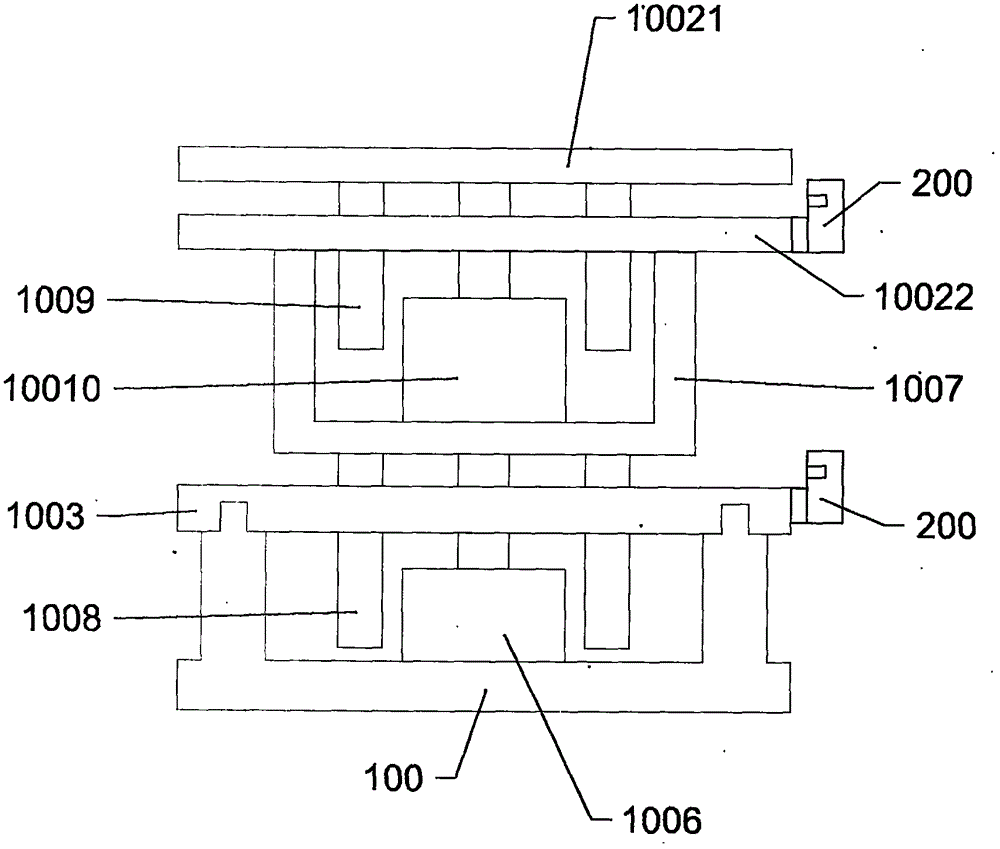

[0034] A fully automatic CNC spectacle frame processing machine, comprising a frame 10, on which a horizontal guide rail 20 is provided, and on the guide rail 20, a spectacles inner frame processing fixing fixture 30 and an outer contour of the spectacles are arranged on the guide rail 20. The processing fixing fixture 40 ; the inner frame processing fixing fixture 30 of the glasses and the outer contour processing fixing fixture 40 of the glasses are used to fix the material to be processed, so as to complete the processing of the glasses frame. Above the guide rail 20 and close to both ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com