Fall-mounted type engine installing vehicle

A technology for installing vehicles and engines, which is applied in the direction of hoisting devices and lifting frames, etc., can solve problems such as the inability to meet the docking work between the engine and the body, and achieve the effects of reasonable design layout, strong reliability, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

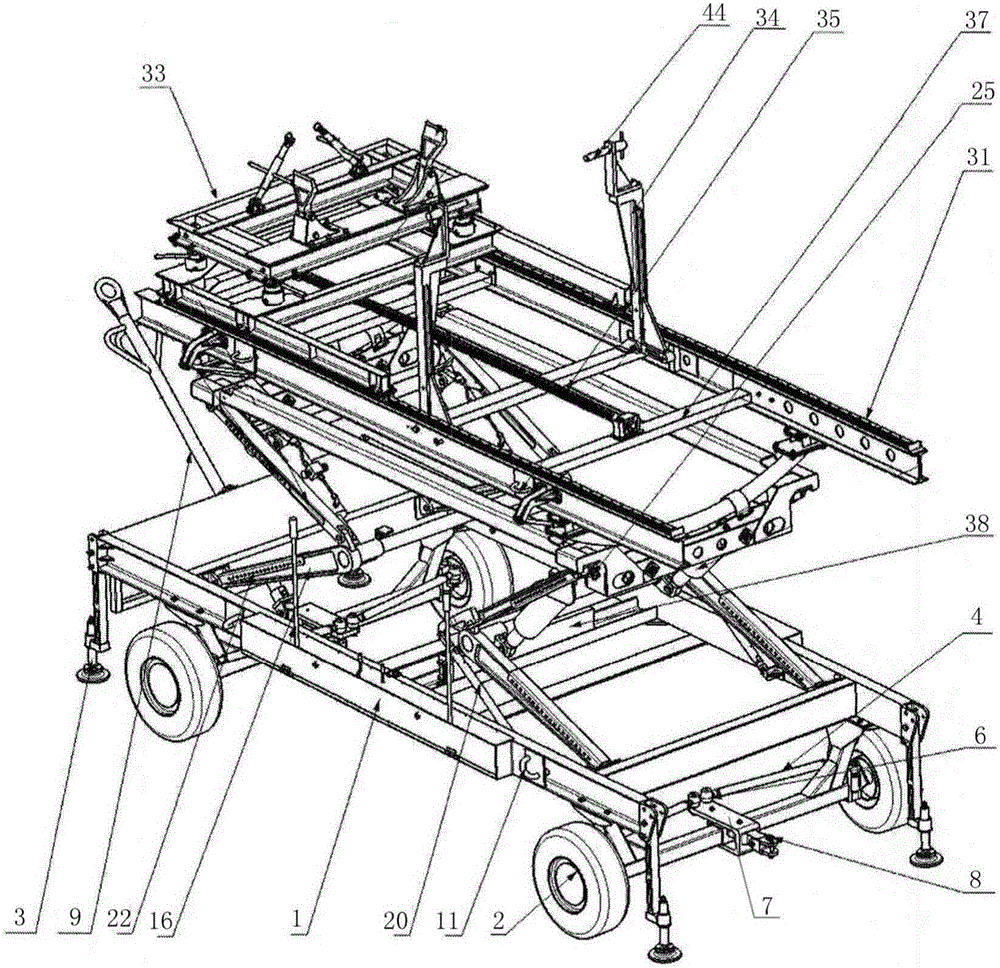

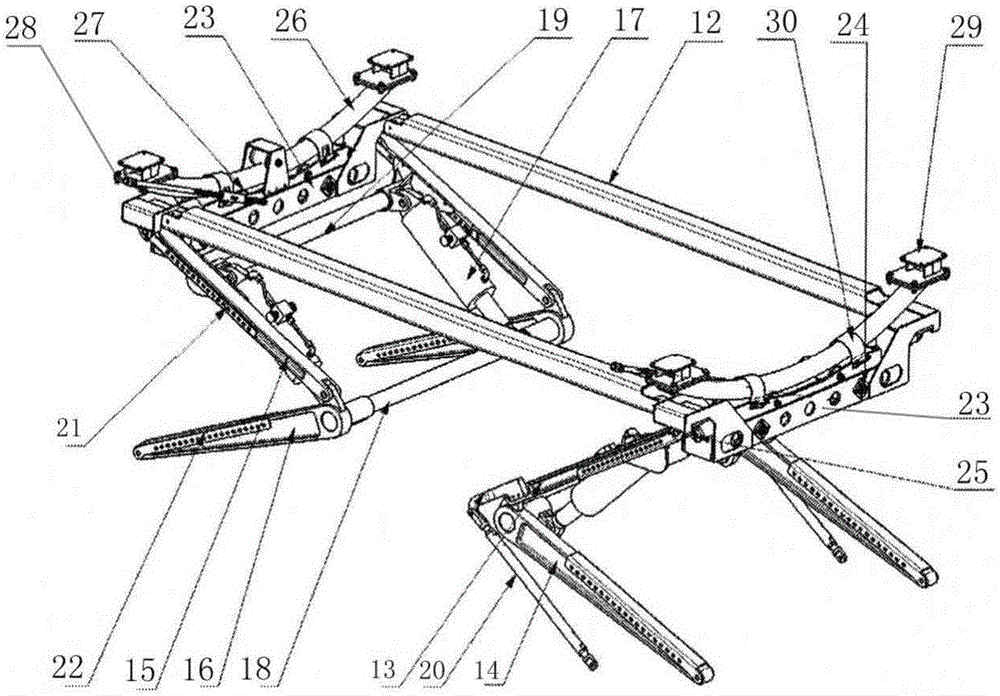

[0020] Such as Figure 1-Figure 5 As shown, the drop-mounted engine installation vehicle is composed of a traveling mechanism, a lifting mechanism, a traversing mechanism, a rolling mechanism, a propulsion mechanism, a fine-tuning mechanism and a hydraulic system.

[0021] The lifting mechanism is installed at the upper end of the traveling mechanism, and the connecting beam 12 fixes the lifting mechanism, the traversing mechanism and the rolling mechanism together, and a propulsion mechanism and a fine-tuning mechanism are installed at the upper end of the traversing mechanism.

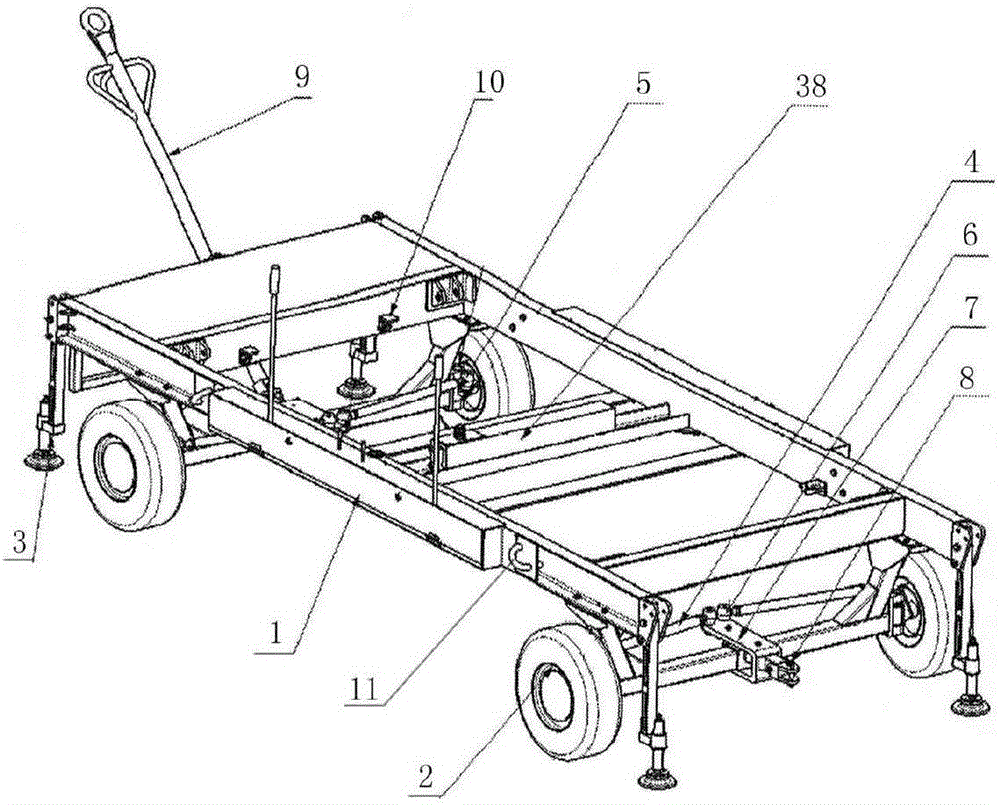

[0022] Such as figure 2 As shown, the walking mechanism is: the chassis 1 is provided with wheels 2 and load-bearing feet 3, and a group of steering traction devices are respectively installed at both ends of the chassis 1. The steering traction device is that the two ends of the tie rod 4 The end is fixed with the chassis 1 through the steering knuckle 5, the middle part of the tie rod 4 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com