H-shaped stiffening rib structure for prolonging service life of steel pipe concrete tubular joint

A technology of concrete-filled steel tubes and intersecting nodes, which is applied in the direction of load-bearing elongated structural components, structural elements, building components, etc., can solve the difficulty of reinforcement and cutting work, and the solution of adding internal partitions cannot be realized. Get practical application and other issues to achieve the effect of prolonging the fatigue life of nodes, increasing the stiffening effect, and taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The patent of the present invention is further described below in conjunction with the accompanying drawings and examples.

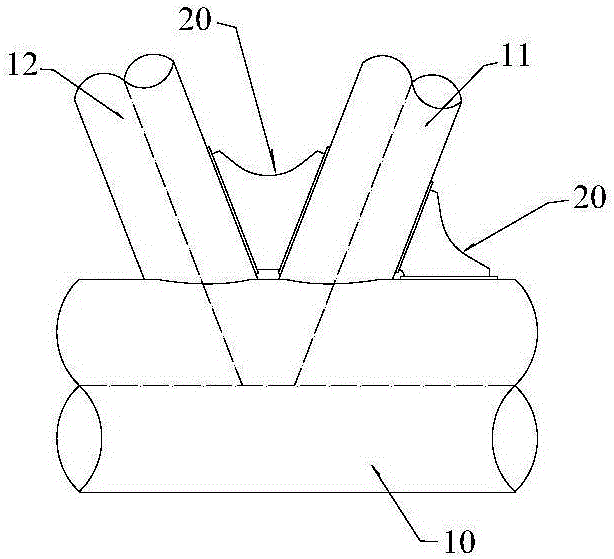

[0021] refer to figure 1 , An H-shaped stiffening rib structure for improving the service life of the intersecting joints of concrete filled steel tubes of the present invention includes a main chord tube 10 and a web tube that is intersected and welded at the node position. Between the main chord tube 10 and the web tube and between the adjacent web tubes, H-shaped stiffeners 20 are arranged at the parts where the stress of the intersecting welds is relatively large. Or adjacent surfaces are attached and bonded together. Through the H-shaped stiffeners 20 bonded and connected with the main chord 10 and the web tube, the fatigue stress amplitude of the intersecting joints of CFST can be effectively reduced, thereby prolonging the joint fatigue life.

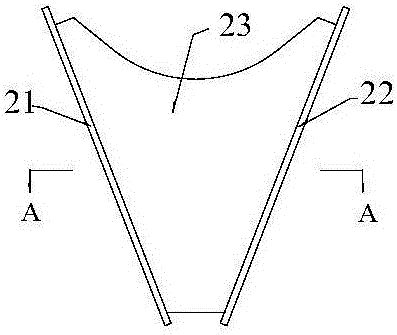

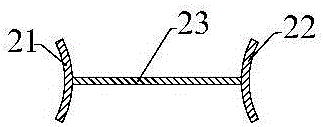

[0022] refer to figure 2 The H-shaped stiffening rib 20 has a first base plate 21, a second b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com