Steel net cage filling body

A filling body and net cage technology, which is applied to building components, floors, buildings, etc., can solve the problems of inability to effectively guarantee the quality of concrete pouring, poor integrity of filling materials, and large buoyancy of filling materials, and achieve good economy and applicability. Good heat insulation effect and high overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

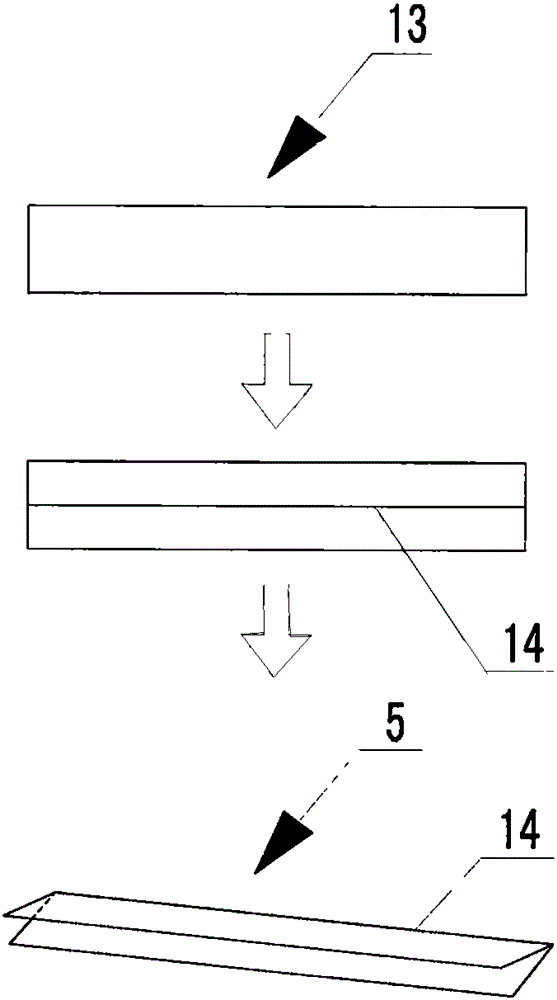

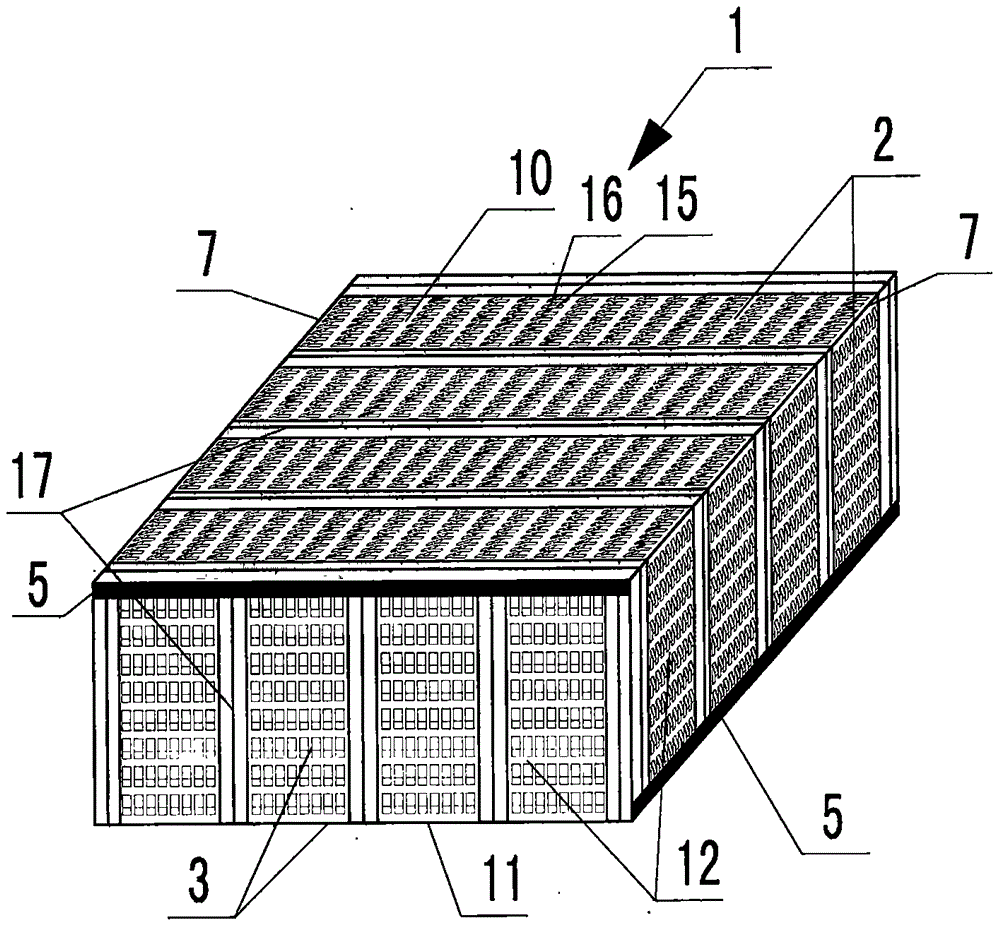

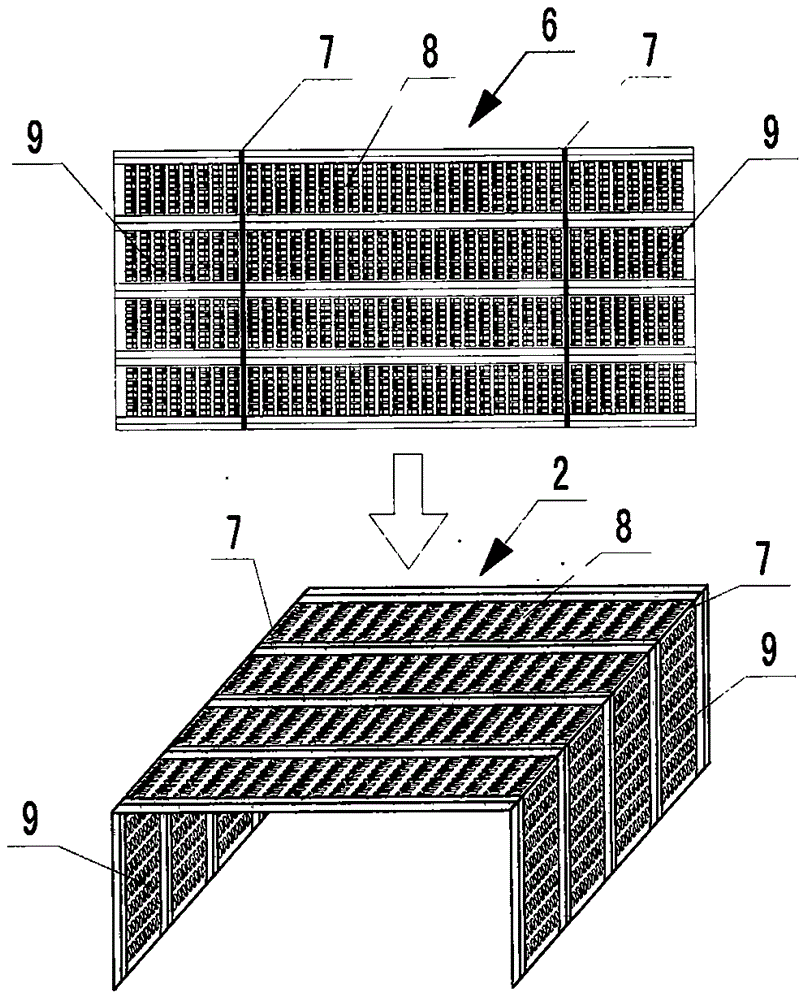

[0034] The present invention is realized in the following manner:

[0035] exist Figure 1-Figure 8 , Figure 11 In the shown embodiment, a kind of packing body of steel net cage, this packing body (1) comprises upper member (2), lower member (3), inner support member (4), side reinforcement member (5), upper member and The lower part is made of a strip-shaped closing net (6) with a thickness of steel plate less than 0.5mm. There are 2 bending lines (7) on each closing net, and the bending lines divide the closing net into 1 panel (8), 2 panels The side plate (9) bends the two ends of the closing net along the bending line to the same direction by 90° respectively to form a U-shaped structure upper member (2) and lower member (3) with 3 faces and 2 sides. At least one inner support (4) is installed in the upper component and the lower component, the upper component and the lower component are buckled together, and the upper component and the lower component are connected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com