Split type angle code

A split type, corner code technology, applied in the field of split type corner codes, can solve the problems of complex structure, scratching people, cumbersome and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

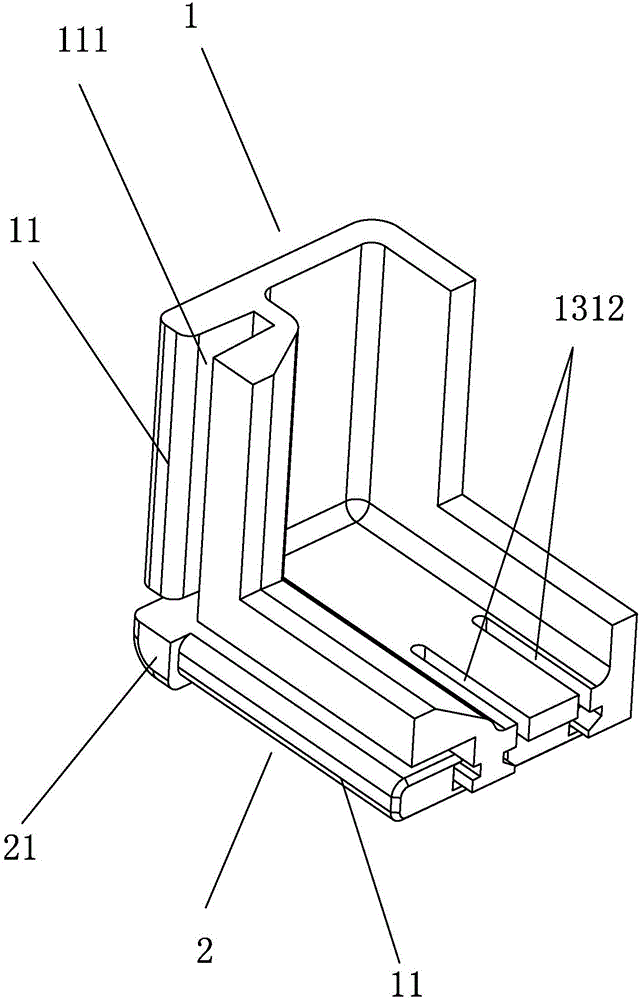

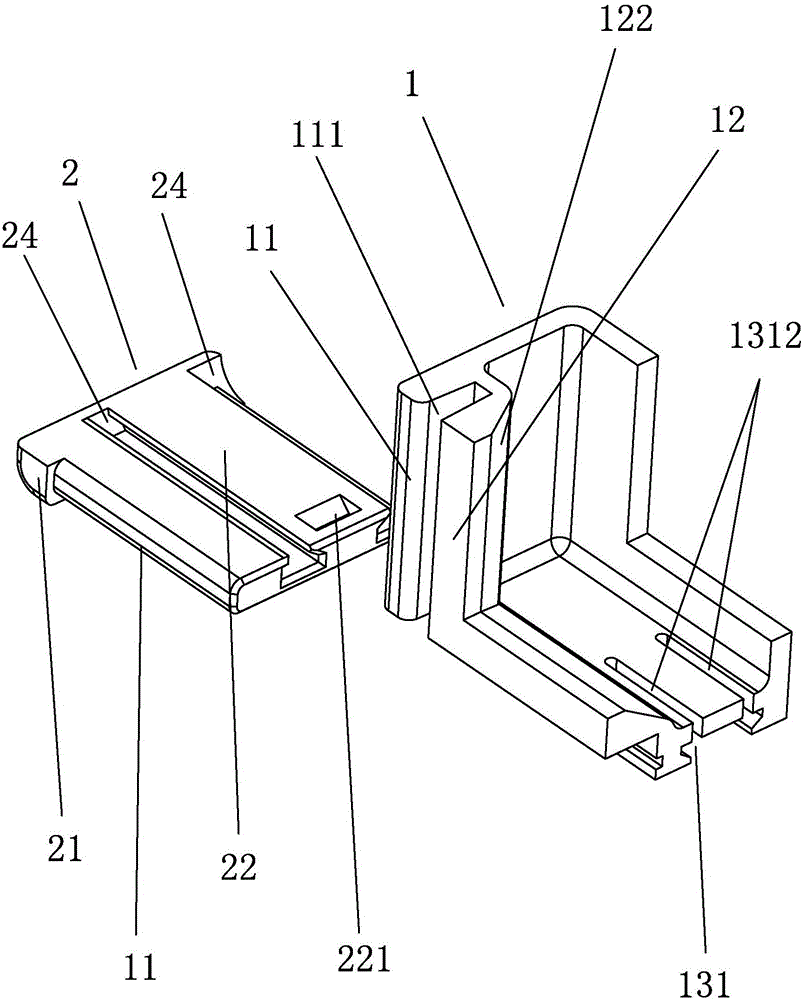

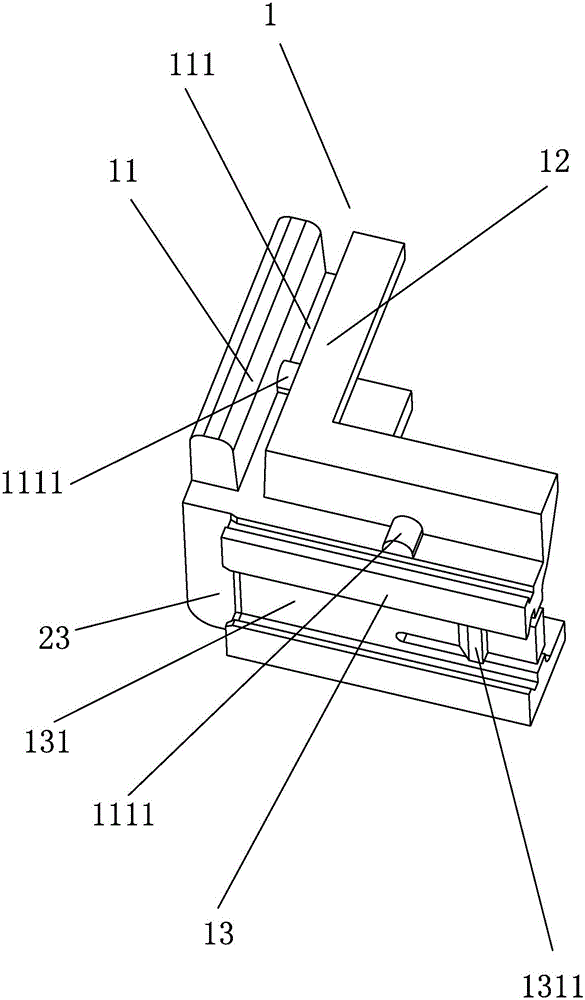

[0024] refer to Figure 1~5 , a split-type corner bracket, including a first mounting block 1 and a second mounting block 2 matched with the edge of the frame body, the first mounting block 1 is formed at an angle, and the forming angle of the first mounting block 1 is in line with the frame body The edge joint angles are consistent, the first installation block 1 and the second installation block 2 include an insertion edge 11 matching with the edge of the frame, the second installation block 2 is fastened with the first installation block 1, and the second installation block 2 is provided with Corner guards 21 matched with the corners of the frame body.

[0025] The insertion edge 11 and the edge of the frame body are interference fit to achieve the effect of mutual pressure. The edge of the frame body is provided with a card position 3, and the inner side of the insertion edge 11 is provided with a protrusion 1111 for engaging with the card position 3 on the edge of the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com