Wind driven generator and combined blade thereof

A technology of combining blades and nacelles, which is applied in wind turbine combinations, wind turbines, wind power generation, etc., can solve the problems of high cost, difficult risks, and high production costs of large wind turbines, reducing requirements, manufacturing costs and transportation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. Attached below Figures 1 to 4 Specific examples of the present invention will be described in detail.

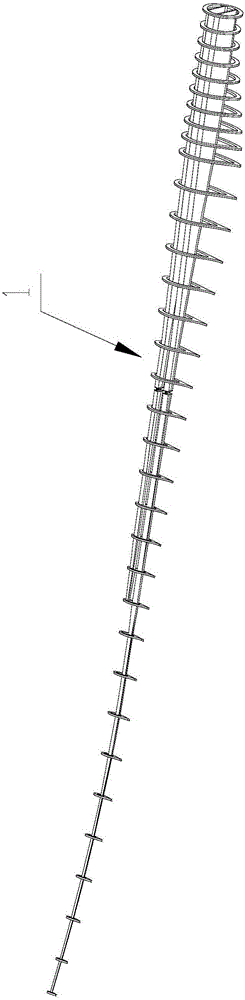

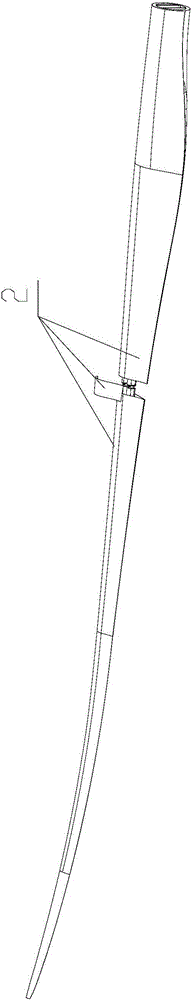

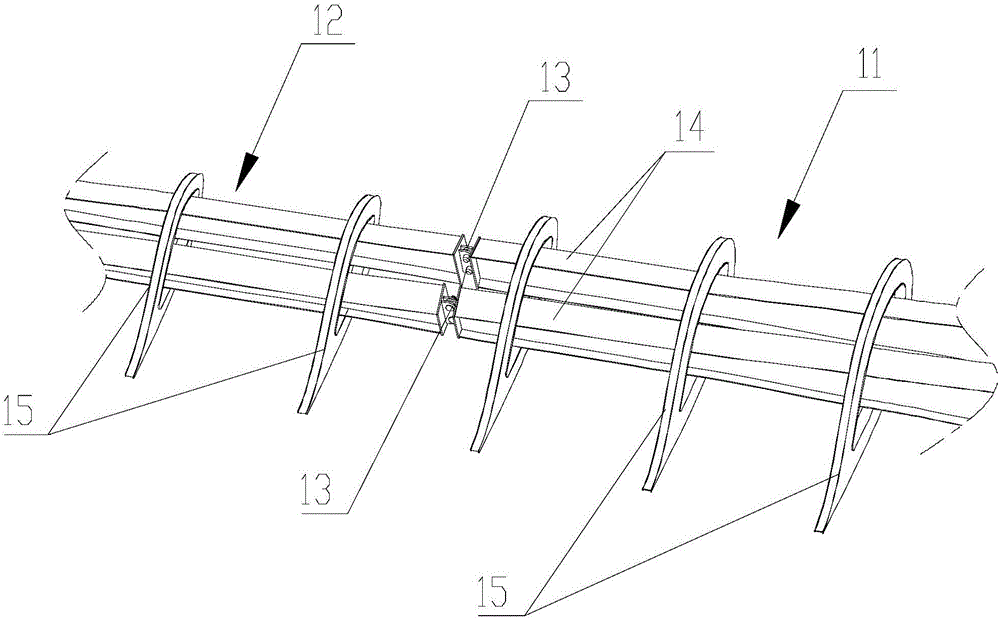

[0026] The combined blade provided by the specific embodiment of the present invention includes a central skeleton 1 and a skin 2, such as figure 1 and image 3 As shown, the central frame 1 includes a main beam 14 and a rib ring 15, and a plurality of rib rings 15 are fixed on the main beam 14 at intervals, and the main beam 14 passes through the central hole of the rib ring 15, as figure 2 As shown, the skin 2 covers the surface of the central frame 1, the skin 2 is fixed relative to the rib ring 15 and the main beam 14, and the force of the skin 2 is transmitted from the rib ring 15 to the main beam 14; the shape of the rib ring 15 is consistent with the blade The cross-sectional shape of the rib rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com