Test method for verifying reliability of transition joint

A technology for transition joints and test methods, which is applied in environmental/reliability testing, measuring devices, instruments, etc., can solve the problems of lack of systematic test methods for transition joints of oil-paper insulated cables and cross-linked insulated cables, and improve the test accuracy. , good electrical performance, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings of the description;

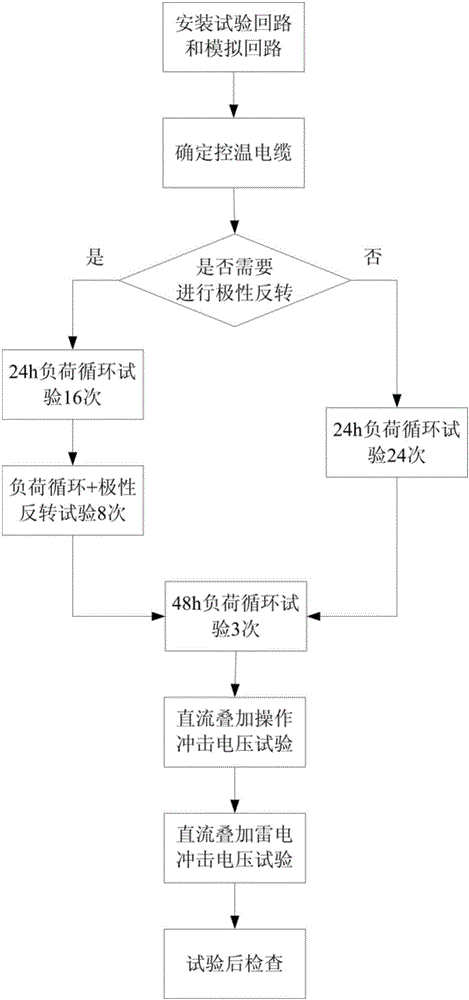

[0033] like figure 1 Shown, the present invention comprises the steps:

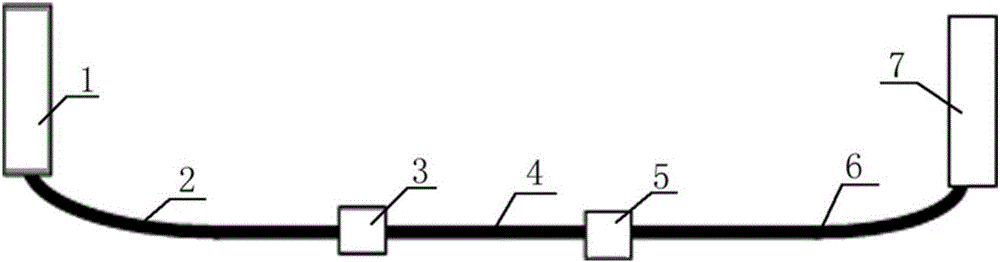

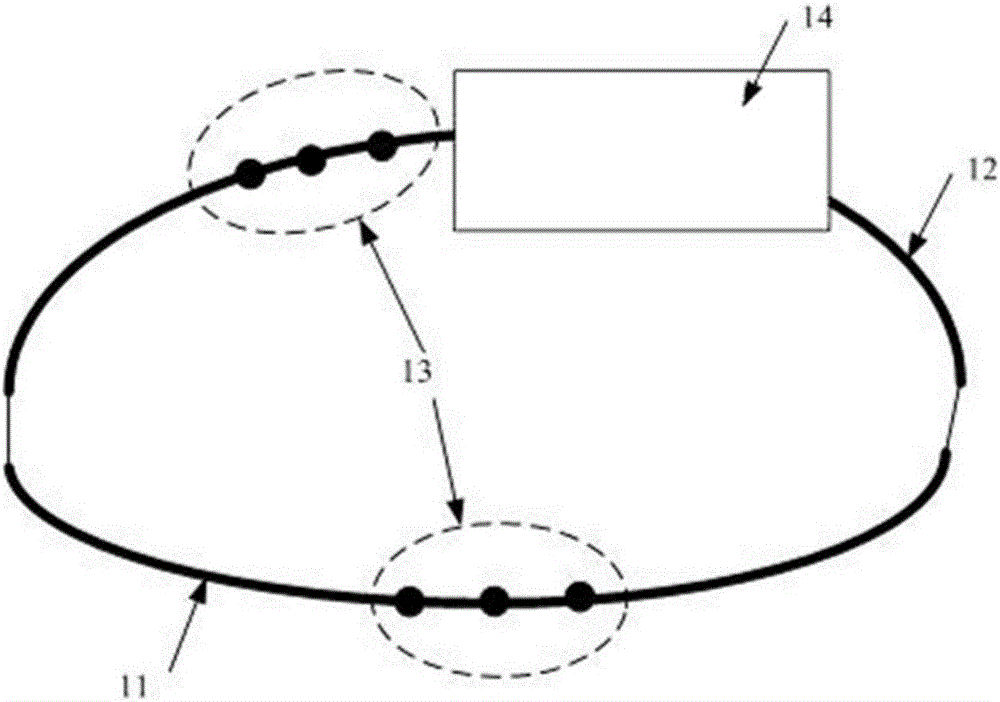

[0034] 1) Install the test loop and simulation loop. Install the test circuit according to the method of "dry terminal 1 + cross-linked insulated cable 2 + transition joint 3 + oil-paper insulated cable 4 + transition joint 5 + cross-linked insulated cable 6 + dry terminal 7", as attached figure 2 As shown, the length of each section of cable is at least 8m; connect the oil-paper insulated cable 11 and the cross-linked insulated cable 12 to form a simulated circuit, as shown in the attached image 3As shown, the length of each section of cable is at least 8m, and each section of cable is equipped with three thermocouples 13 to measure the conductor temperature, and the installation distance of thermocouples 13 should not be less than 0.5m. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com