Power pack testing system

A test system and power battery technology, applied in the direction of testing dielectric strength, measuring electricity, measuring devices, etc., can solve problems such as low degree of automation, inability to meet test requirements, low efficiency, etc., to reduce manual operations, improve test efficiency, The effect of reducing production test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the drawings.

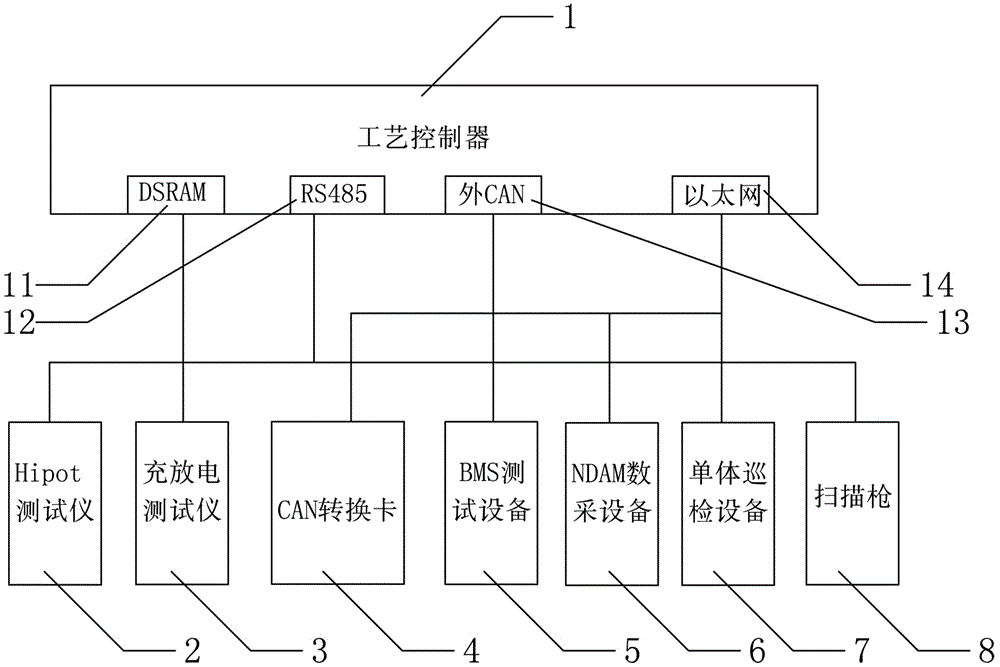

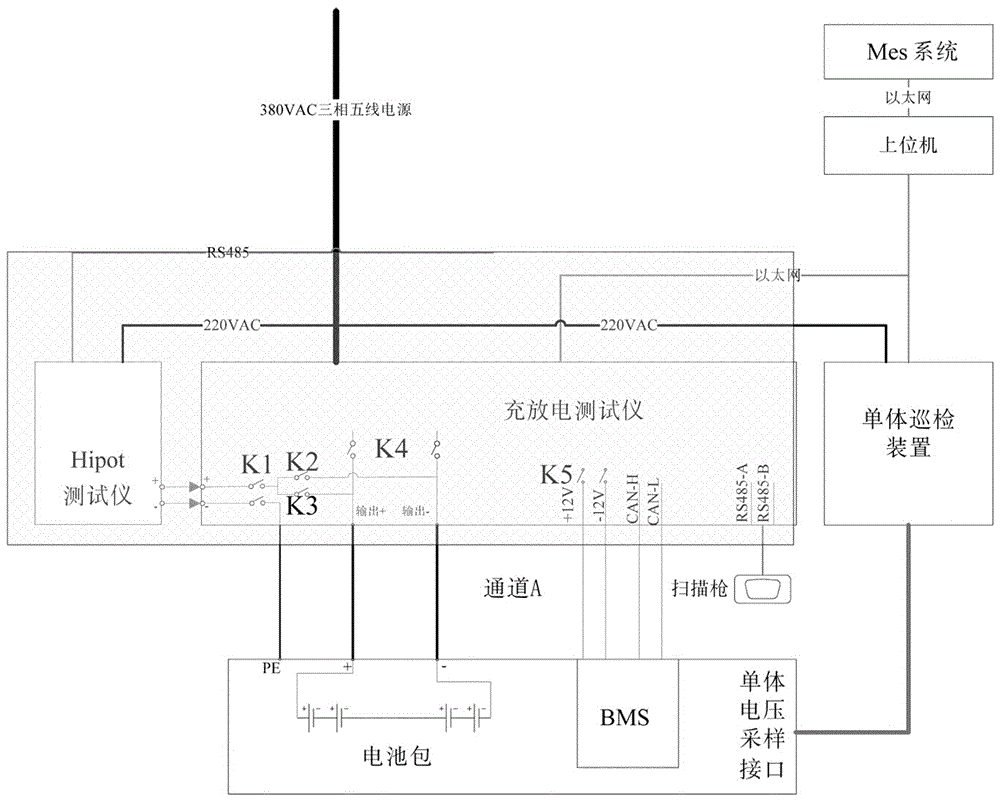

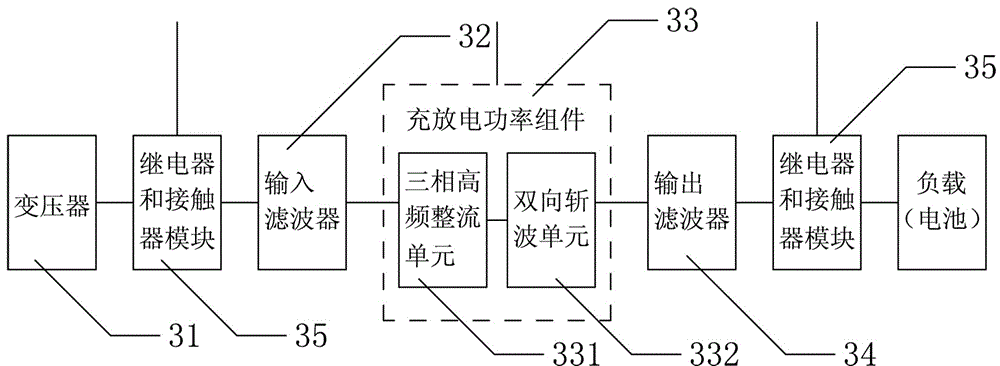

[0022] Reference figure 1 , figure 2 As shown, a single-channel power battery pack test system includes:

[0023] Process controller 1, used to receive and analyze the upper computer test plan, complete the instruction decomposition and control each sub-equipment to complete the related test process, and at the same time package and upload real-time data integration and rapid recording of detailed test data to the host computer system, process controller 1 There are DSRAM interface 11, RS485 interface 12, CAN interface 13, and Ethernet interface 14.

[0024] The insulation withstand voltage tester 2 is used to perform insulation withstand voltage detection and leakage current detection on the Pack battery pack. As a specific embodiment, the insulation withstand voltage tester 2 is a Hipot tester, which is selected in the embodiment Tester with model Chroma 19073; Image 6 Flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com