Optical fiber collimating device and assembling method thereof

A technology of optical fiber alignment and optical fiber, applied in the direction of light guides, optics, optical components, etc., can solve the problems of increasing V-shaped grooves and movable workbench processing difficulties and high processing costs, and achieves simple structure, reduced processing costs, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

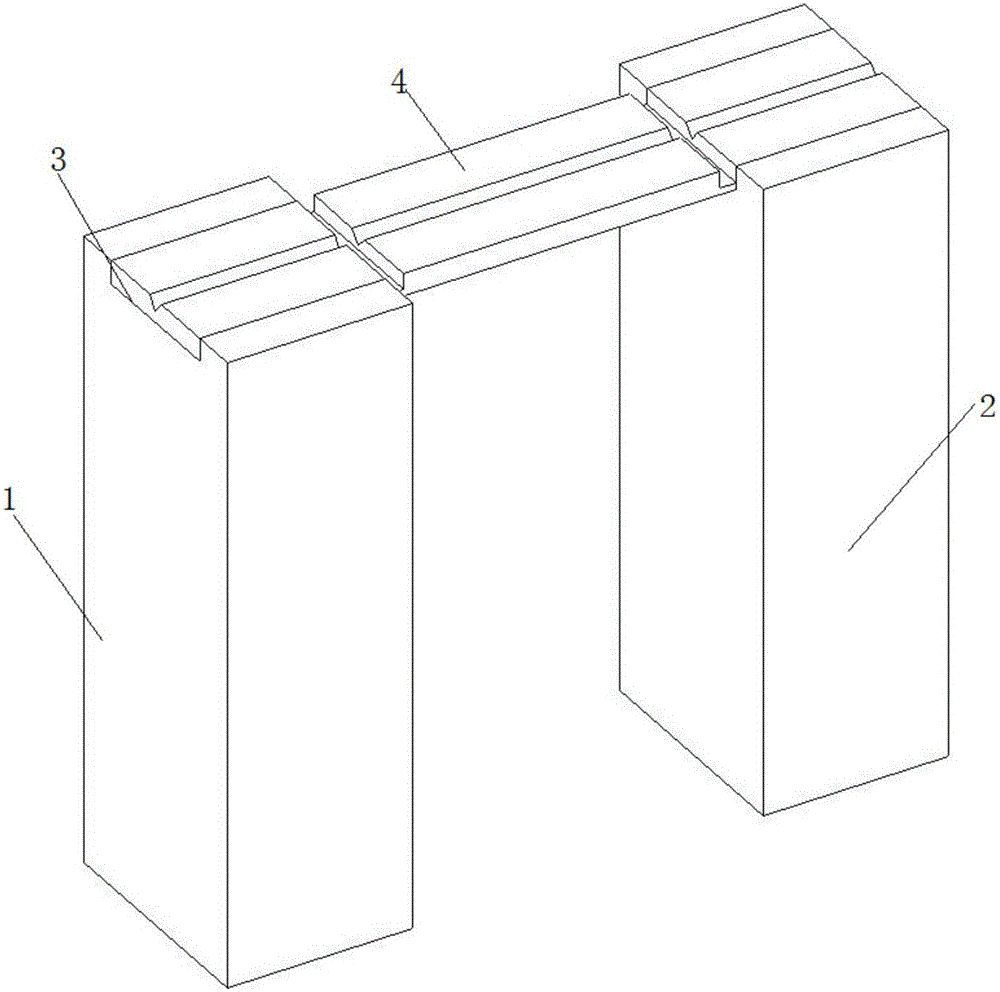

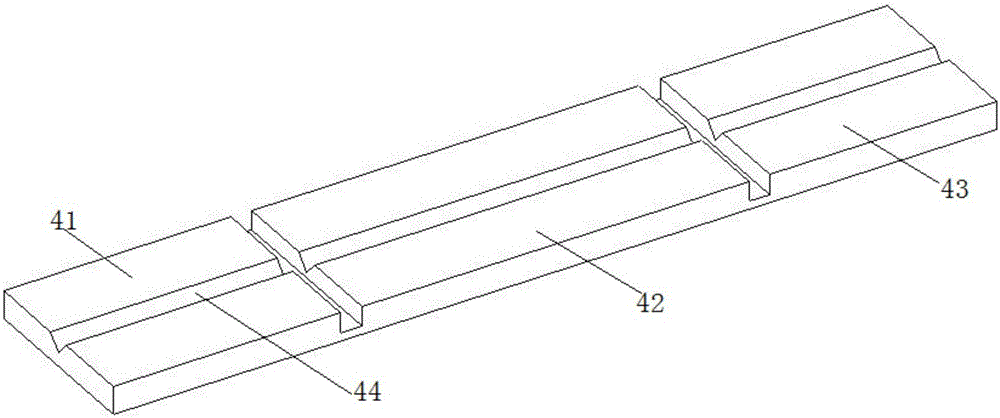

[0019] Such as Figure 1-2 As shown, an optical fiber collimation device includes a substrate 4 and a substrate support table. The substrate 4 is made of silicon wafer or ceramic material. The substrate 4 is set on the substrate support table. The substrate 4 includes a first fiber carrying portion 41 and an intermediate interconnection. The first optical fiber carrying portion 41, the intermediate interconnecting portion 42 and the second optical fiber carrying portion 43 are processed on the substrate 4 by photolithography or molding followed by auxiliary processing methods. A V-shaped groove 44 intersecting and having a V-shaped cross section is provided at the central axis of the portion 41, the intermediate interconnecting portion 42 and the second fiber carrying portion 43.

[0020] The substrate support table i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com