Touch screen manufacturing method and touch screen

A manufacturing method and touch screen technology, applied in instruments, computing, electrical digital data processing, etc., can solve problems such as various traces, uneven display brightness, abnormal appearance, etc., to avoid mura, improve appearance visibility, and increase efficiency. and performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described below based on examples, but the present invention is not limited to these examples. In the following detailed description of the present invention, some specific details are described in detail. Those skilled in the art can fully understand the present invention without the description of these details. In order to avoid obscuring the essence of the present invention, well-known methods, processes, procedures, and components are not described in detail.

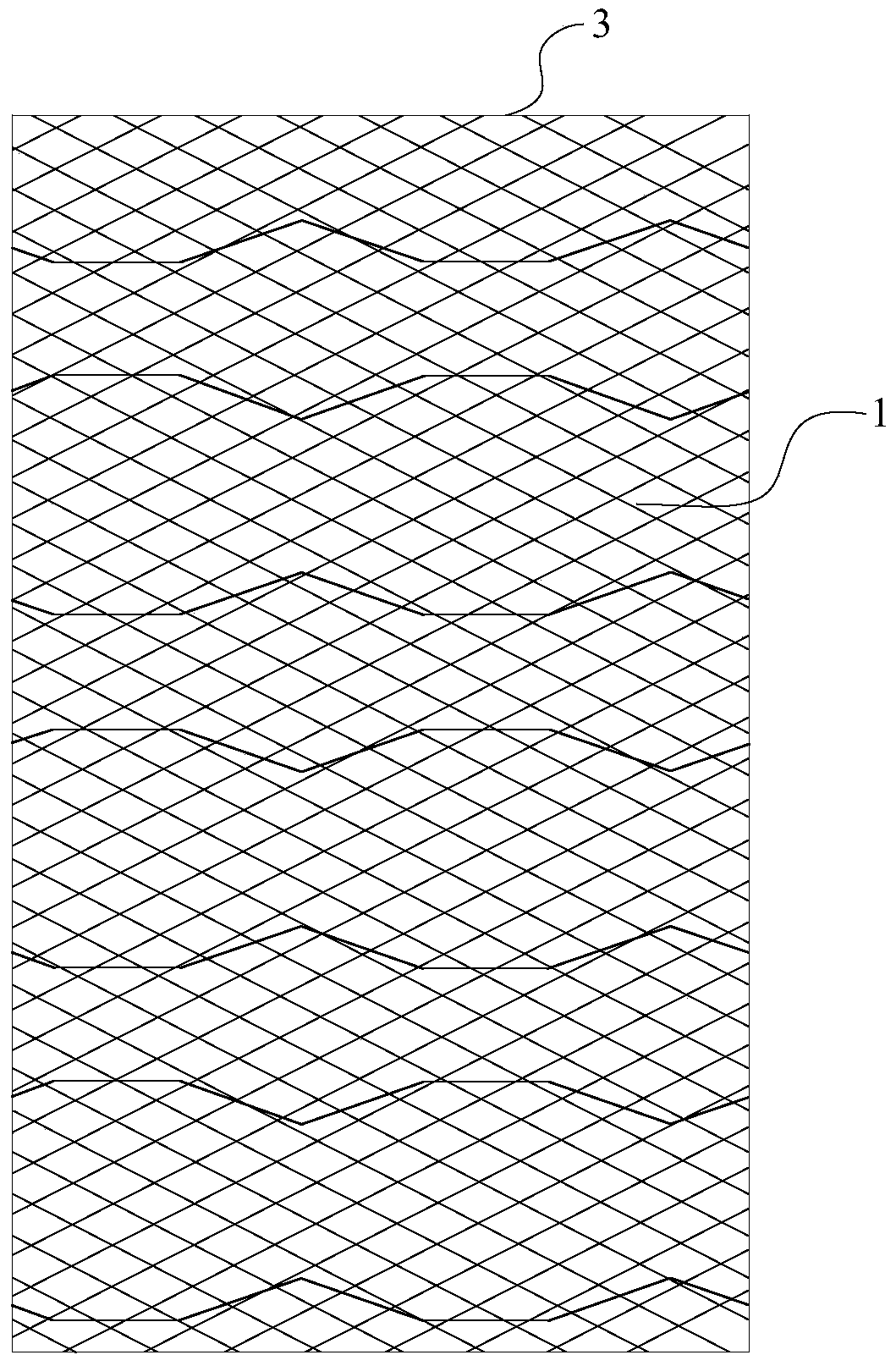

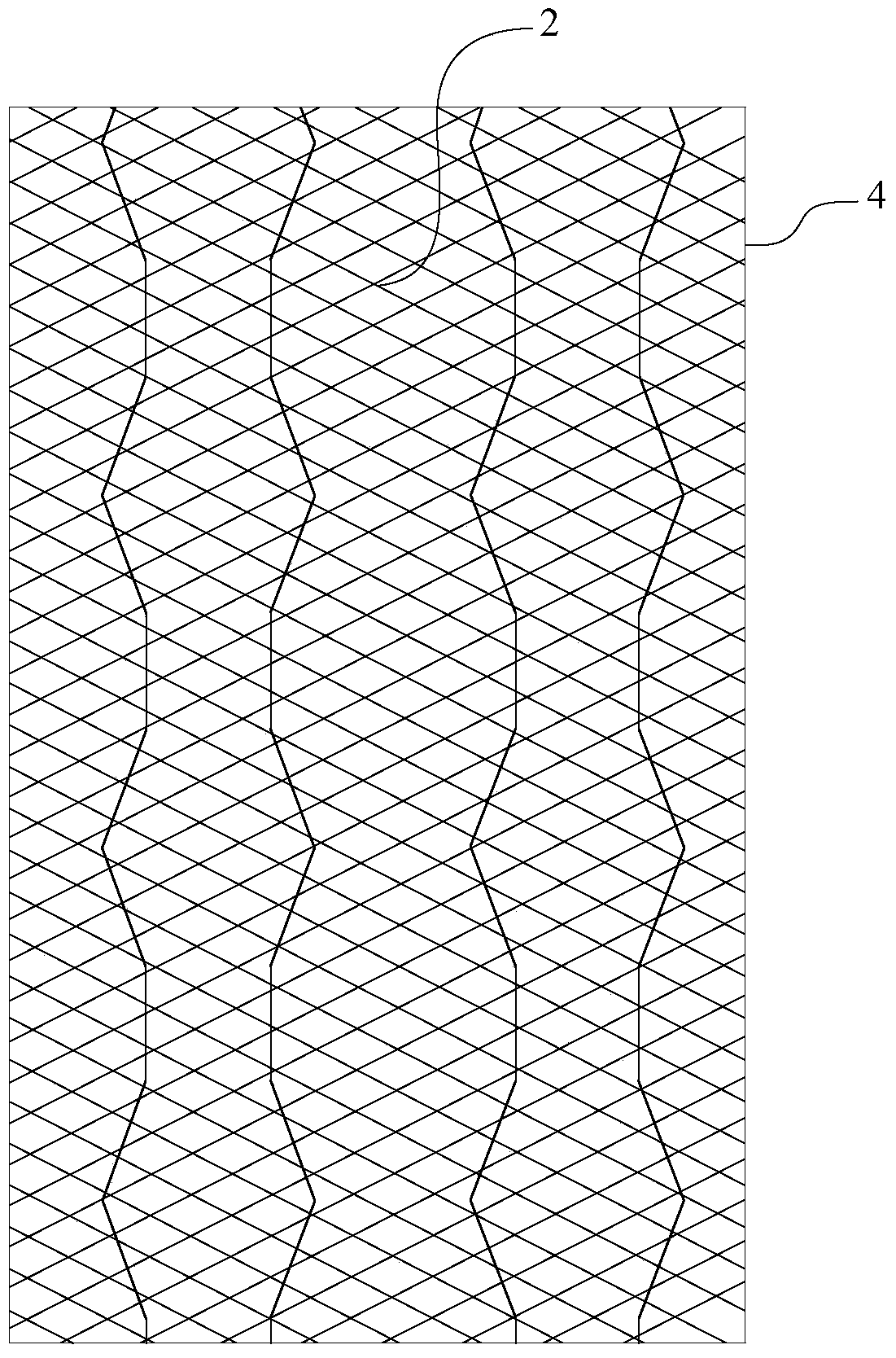

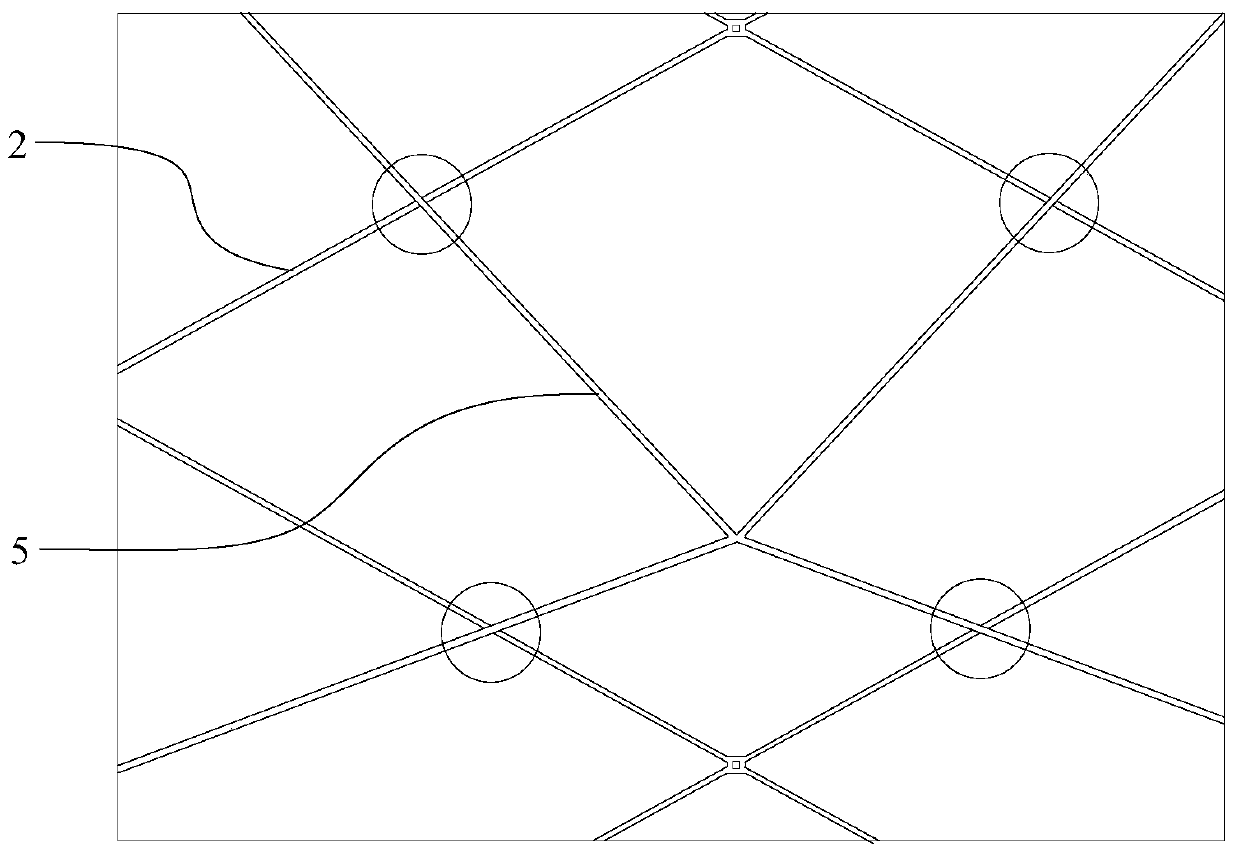

[0038] The present invention provides a method for manufacturing a touch screen. The touch screen includes a first grid electrode layer and a second grid electrode layer that are stacked, and the method includes:

[0039] Providing a laminated first grid conductor layer and a second grid conductor layer;

[0040] Cutting the first grid conductor layer to pattern the first grid conductor layer to form a first grid electrode;

[0041] Cutting the second grid conductor layer to pattern the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com