Hollow microsphere structure lithium ion battery ternary positive electrode material and preparation method thereof

A lithium-ion battery, hollow microsphere technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of difficult to control the baking temperature and method of process conditions, low first charge and discharge efficiency, complex synthesis process, etc. The effect of large reactive area, improved electrochemical performance and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

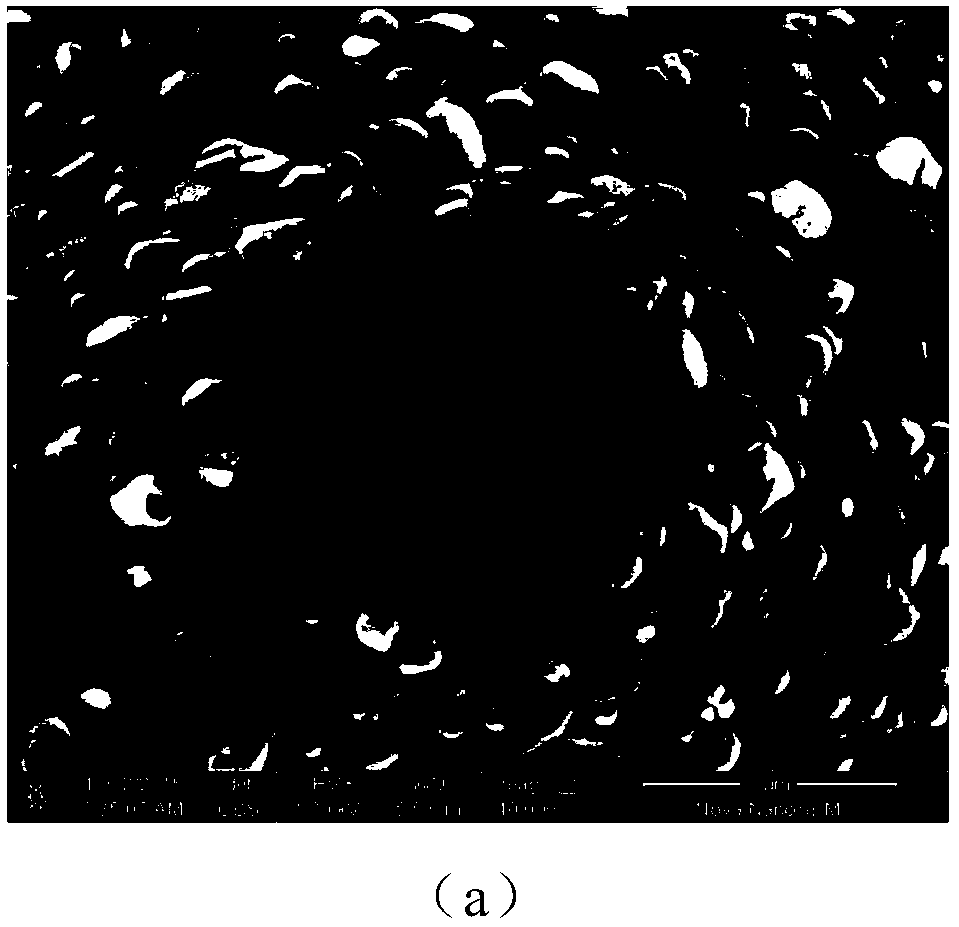

[0051] In this example, LiNi with a diameter of 10 μm was synthesized by the sol-gel method 0.5 co 0.2 mn 0.3 o 2 hollow microspheres. Wherein, the diameter of the primary particles used to assemble the microspheres is not greater than 600nm.

[0052] The preparation method is as follows:

[0053] (1) Weigh 1.1049g anhydrous nickel acetate (Ni(CH 3 COO) 2 ), 0.6227g cobalt acetate tetrahydrate (Co(CH 3 COO) 2 4H 2 O), 0.6488g anhydrous manganese acetate (Mn(CHCOO) 2 ) and 1.3389g lithium acetate dihydrate (LiCH 3 COO·2H 2 O) Dissolve in 30ml deionized water to form solution A.

[0054] (2) Weigh 5.2535g of citric acid and dissolve it in 20ml of deionized water to form solution B.

[0055] (3) Solution B obtained in step (2) was slowly added dropwise to solution A obtained in step (1), stirred at 60°C for 3 hours, then stirred at 80°C for 3-4 hours until a purple transparent sol was formed.

[0056] (4) Dry the sol obtained in step (3) in an oven at 120°C for 12 h...

Embodiment 2

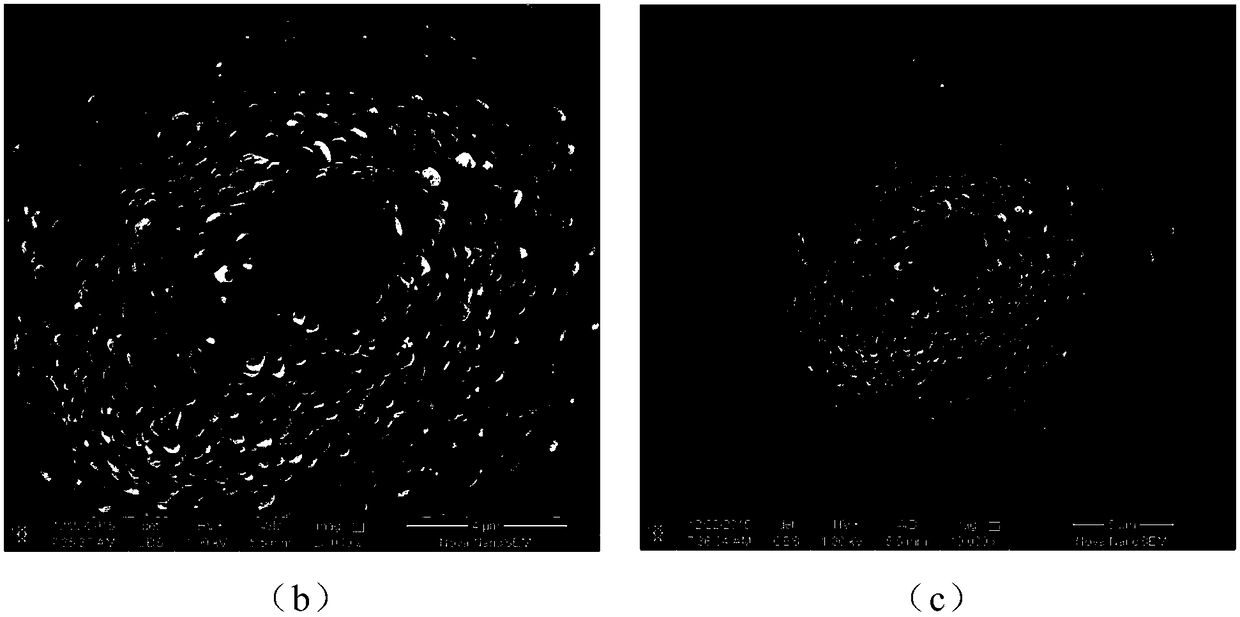

[0062] In this example, LiNi with a diameter of 10 μm was synthesized by the sol-gel method 0.6 co 0.2 mn 0.2 o 2 hollow microspheres.

[0063] The preparation method is as follows:

[0064] (1) Weigh 1.326g of anhydrous nickel acetate (Ni(CH 3 COO) 2 ), 0.6227g cobalt acetate tetrahydrate (Co(CH 3 COO) 2 4H 2 O), 0.4326g anhydrous manganese acetate (Mn(CHCOO) 2 ) and 1.3389g lithium acetate dihydrate (LiCH 3 COO·2H 2 O) Dissolve in 200ml deionized water to form solution A.

[0065] (2) Weigh 3.1521 g of citric acid and dissolve it in 50 ml of deionized water to form solution B.

[0066] (3) Slowly add the B solution obtained in step (2) to the A solution obtained in step (1) drop by drop, adjust the pH to between 7 and 8 with ammonia water, and then stir at 80°C for 5 to 6 hours until a purple color is formed Transparent sol.

[0067] (4) Dry the sol obtained in step (3) in an oven at 180°C for 12 hours to obtain a xerogel; then place the xerogel in a tube furna...

Embodiment 3

[0072] In this example, LiNi with a diameter of 10 μm was synthesized by the sol-gel method 0.5 co 0.2 mn 0.3 o 2 hollow microspheres.

[0073] Concrete steps are identical with embodiment 1, and difference is: the total volume of solution A is 200ml in the step (1); The total volume of solution B is 50ml in the step (2); The stirring system in the step (3) is 80 ℃ of water bath conditions Under 5 ~ 6h, in addition to adjust the pH to between 7 ~ 8.

[0074] from Figure 7 As can be seen from the EDS energy spectrum diagram, the chemical formula of the hollow microspheres obtained by the present invention is LiNi 0.5 co 0.2 mn 0.3 o 2 .

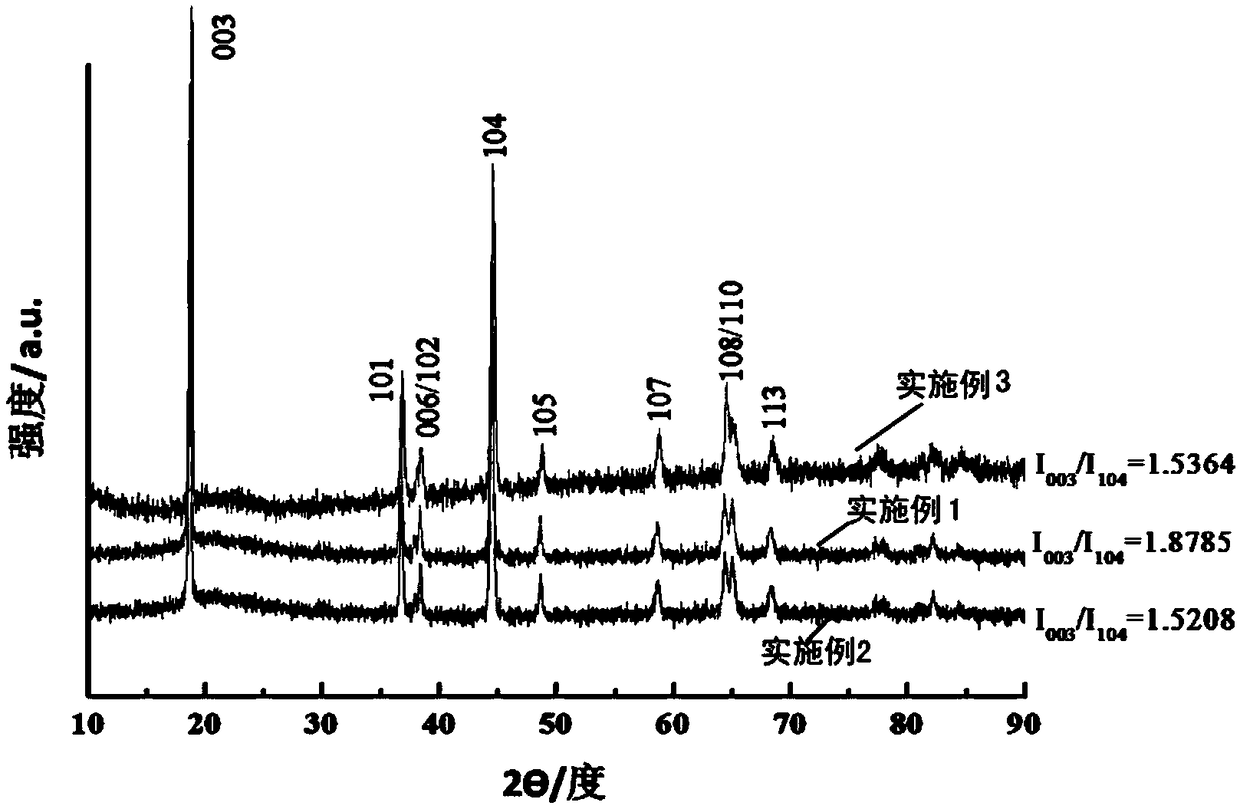

[0075] LiNi prepared in this embodiment 0.5 co 0.2 mn 0.3 o 2 The X-ray diffraction (XRD) pattern of the hollow microspheres is shown in figure 1 , it can be seen from the figure that the peak intensity ratio of 003 and 104 has reached 1.5364 (much greater than 1.2), indicating that the mixing of lithium and nickel is not seriou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com