Emulsification effect enhanced chocolate refiner

An enhanced, chocolate technology, applied in the fields of application, cocoa, food science, etc., can solve the problems of reducing slurry mixing and emulsifying efficiency, insufficient axial throwing force of slurry, easy cooling and solidification of chocolate slurry, etc., to achieve improved shear Cutting and emulsifying effect, improved shearing and emulsifying effect, uniform and comprehensive effect of heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

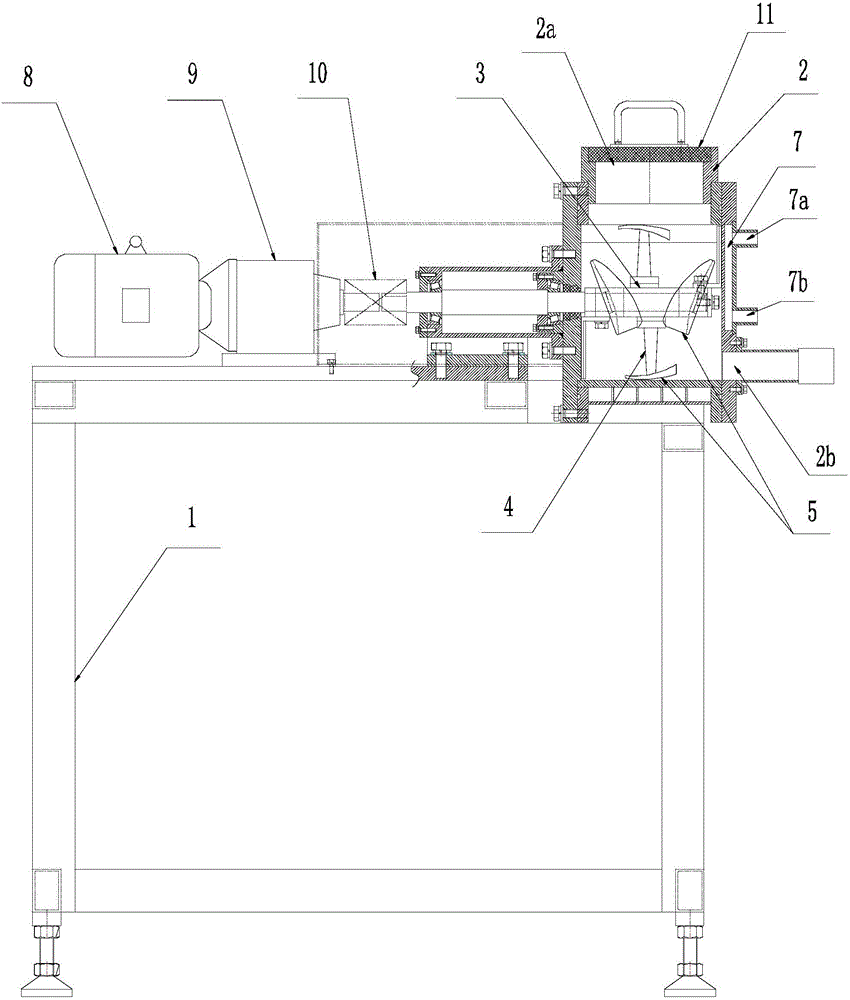

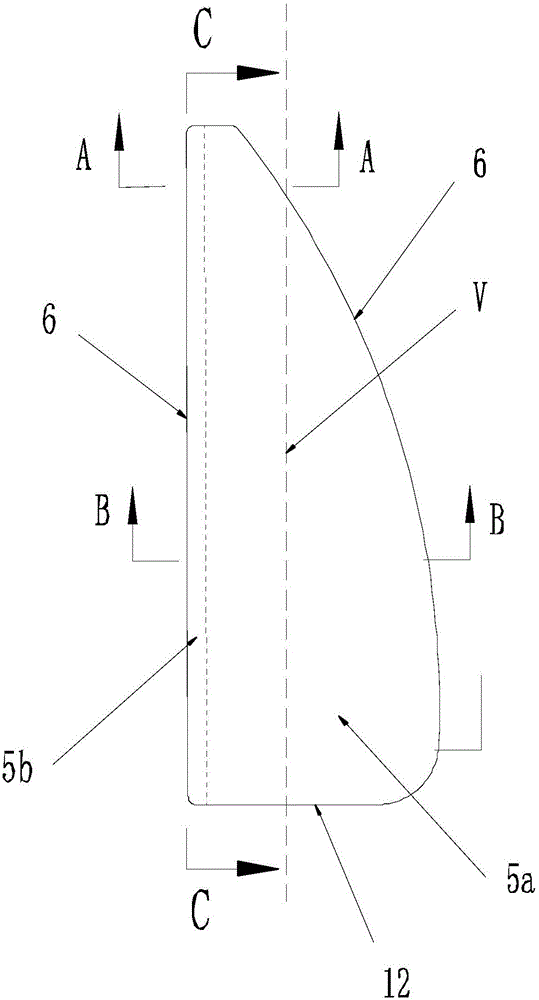

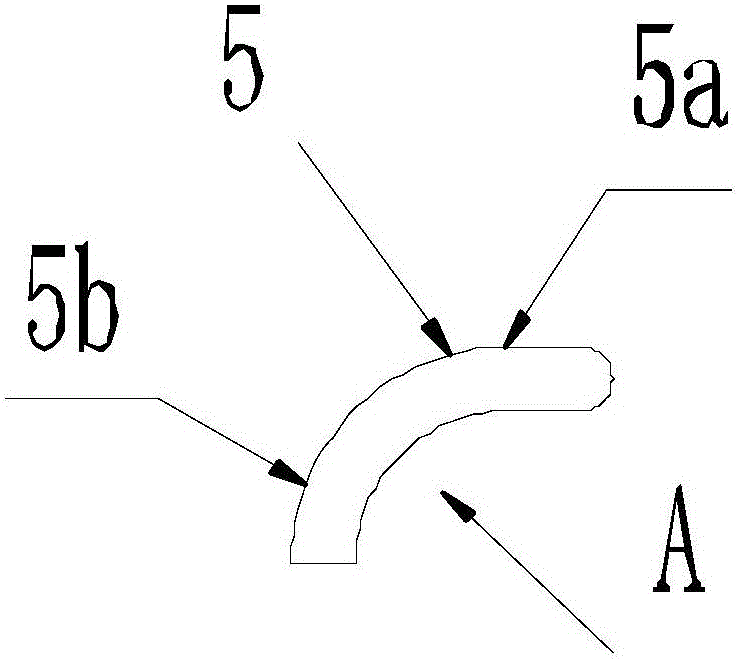

[0033] Example: Combining Figure 1~Figure 5 The structure of the conch with enhanced emulsification effect of the present invention is explained in detail as follows. First as figure 1 As shown, the frame 1 of the present invention is provided with a driving device and a material cylinder 2, and a stirring mechanism is provided in the material cylinder 2, and the stirring mechanism is connected with the driving device and driven by it.

[0034] The driving device in this embodiment is specifically composed of a motor 8, a reducer 9 and a coupling 10. The output shaft of the motor 8 is connected to the rotating shaft 3 in the stirring mechanism via the reducer 9 and the coupling 10, and The motor 8 is a forward and reverse motor. The top of the material cylinder 2 is provided with a feeding port 2a, the feeding port 2a is provided with a cover 11, and the bottom of the material cylinder 2 is provided with a discharging port 2b transversely. The present invention also has a slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com