Flotation reagent emulsification equipment and method thereof

A technology of flotation reagents and emulsification equipment, which is applied in the direction of chemical instruments and methods, mixing methods, dissolution, etc., can solve the problems of short emulsification path, unstable emulsion, demulsification, etc., and achieve the effect of improving the emulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, specific implementations of the present invention will be described in conjunction with illustrative examples and with reference to the accompanying drawings.

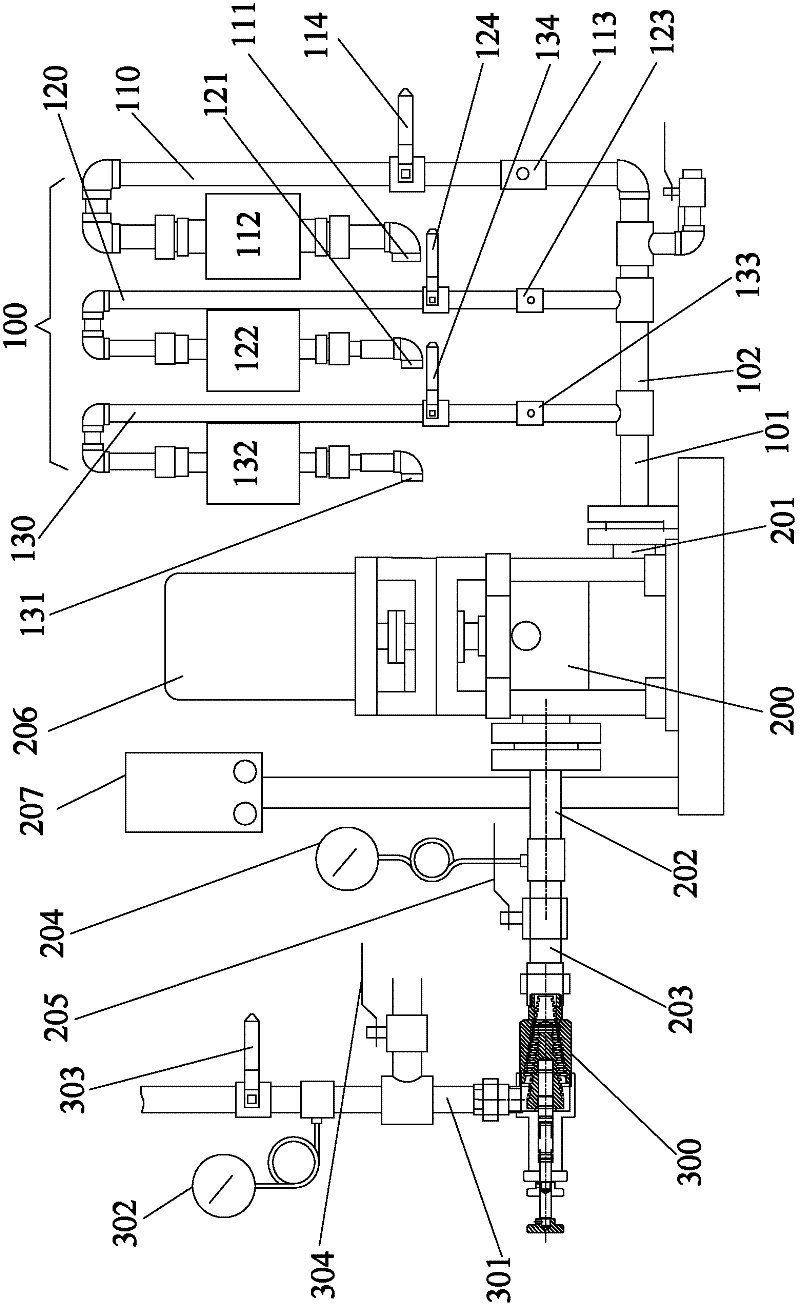

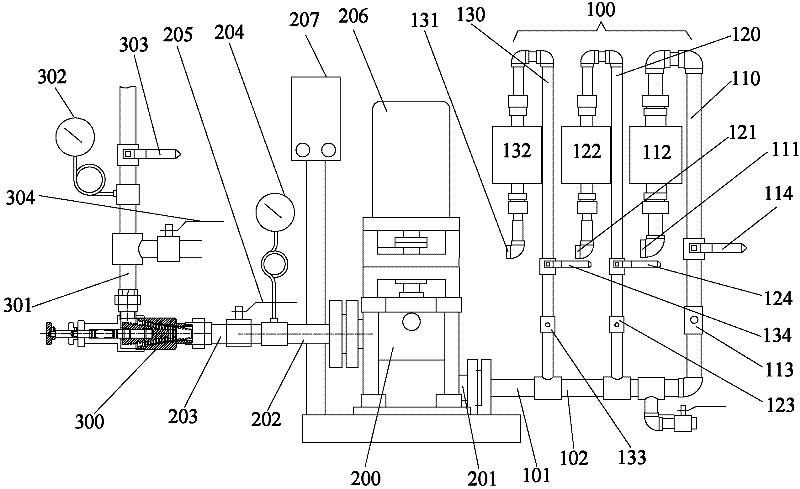

[0027] figure 1 A schematic structural diagram of a flotation agent emulsification device according to a preferred embodiment of the present invention is shown.

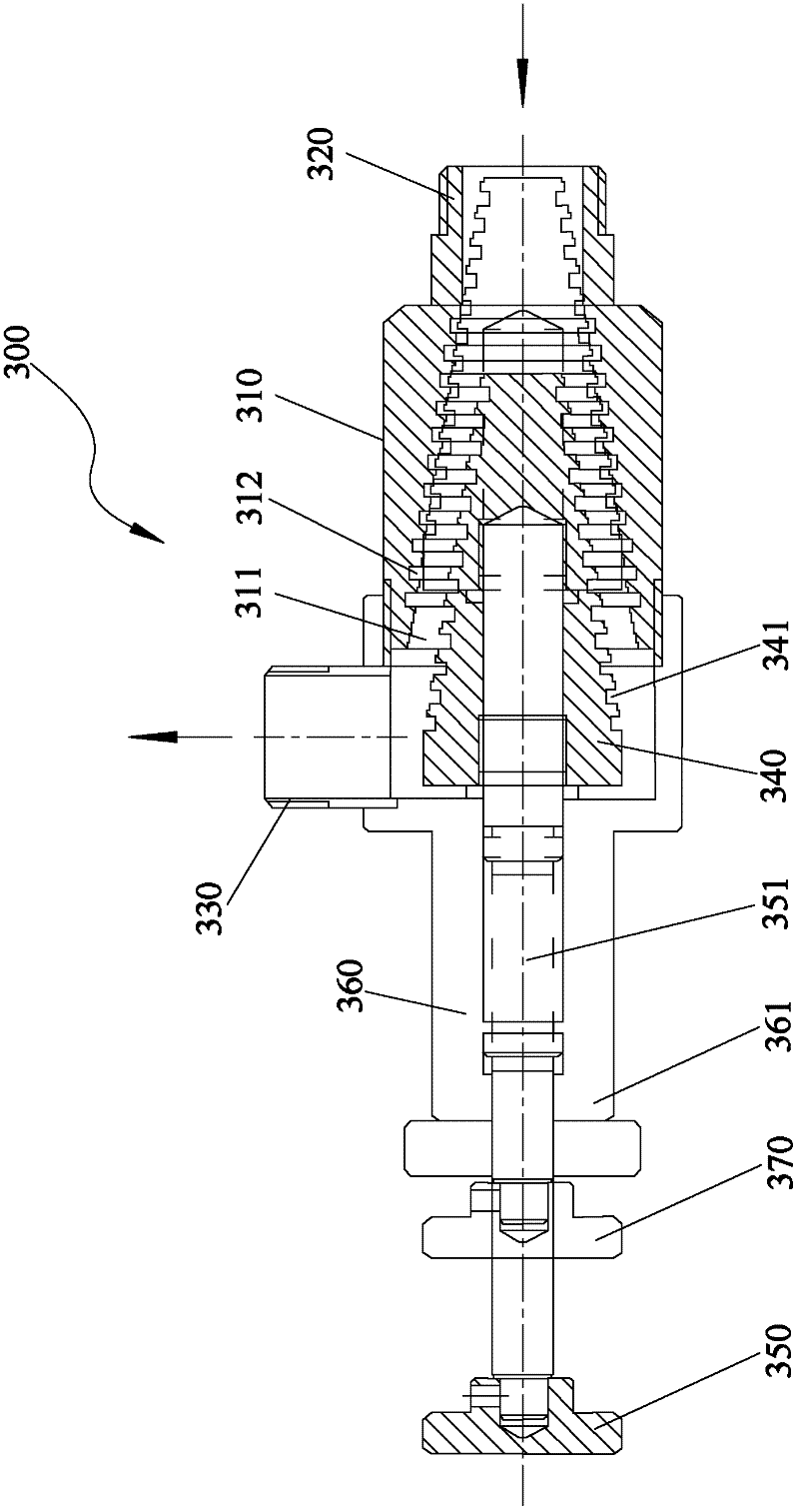

[0028] figure 1 The medium flotation reagent emulsification equipment mainly includes a raw material distribution device 100 , a multistage pump 200 and an emulsifier 300 . The raw material distributing device 100 includes three input ends 111, 121 and 131, and the three input ends 111, 121 and 131 are respectively connected with corresponding material storage containers, so as to obtain materials from the material storage containers. The input end 201 of the multi-stage pump 200 is connected with the output end 101 of the raw material distribution device 100, so that the material is sucked from the raw material distribution device 100, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com