Production process of paraffin emulsion with high solid content

A production process and technology of paraffin wax emulsion, applied in the direction of wax physical treatment, mixer with rotating stirring device, mixer, etc., can solve the problems of unstable viscosity of emulsion and difficult emulsification of paraffin wax, so as to improve the emulsification effect and solve the problem of interfacial film Non-densification, improve the effect of high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

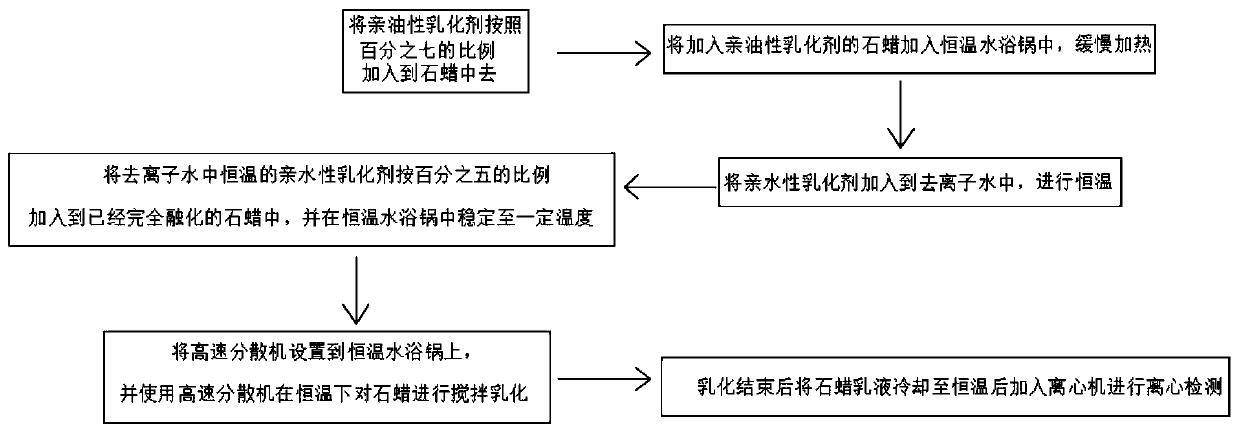

[0034] A high-solid-content paraffin emulsion production process includes a production process, and the production process includes the following steps:

[0035] 1) Prepare raw materials such as industrial grade refined paraffin, deionized water, lipophilic emulsifier and hydrophilic emulsifier, and then prepare high-speed disperser, constant temperature water bath and centrifuge and other equipment;

[0036] 2), the lipophilic emulsifier is added into the paraffin according to the ratio of 7%. The oily emulsifier will adsorb on the interface to form a certain strength interfacial film. After the lipophilic emulsifier is added to the preset value of 7%, the interface will be completely covered by the emulsifier molecules, forming a complete protective film and establishing a stable dual Electrical layer, thereby improving the stability of the emulsion;

[0037] 3) Add the paraffin wax with lipophilic emulsifier into the constant temperature water bath, and heat slowly;

[00...

Embodiment 2

[0052] A high solid content paraffin emulsion production process, including the production process, the production process includes the following steps: 1), prepare raw materials such as industrial-grade refined paraffin, deionized water, lipophilic emulsifier and hydrophilic emulsifier, and then Prepare high-speed dispersing machine, constant temperature water bath and centrifuge and other equipment;

[0053] 2) Add the lipophilic emulsifier to the paraffin wax at a ratio of 10%. When the amount of the lipophilic emulsifier is 10%, the emulsification speed will be increased to a certain extent, and the excess emulsifier will form micelles , thus enhancing the dissolution in aqueous phase substances;

[0054] 3) Add the paraffin wax with lipophilic emulsifier into the constant temperature water bath, and heat slowly;

[0055] 4), adding the hydrophilic emulsifier into the deionized water and keeping the temperature constant;

[0056] 6) Add the constant-temperature hydrophil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com