Tank shell type liquid level adjusting device for desulfurizing tower

A technology of liquid level adjustment device and desulfurization tower, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of increasing the contact surface, etc., and achieve the effects of stable operation, stable operation, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, the present invention will be further described:

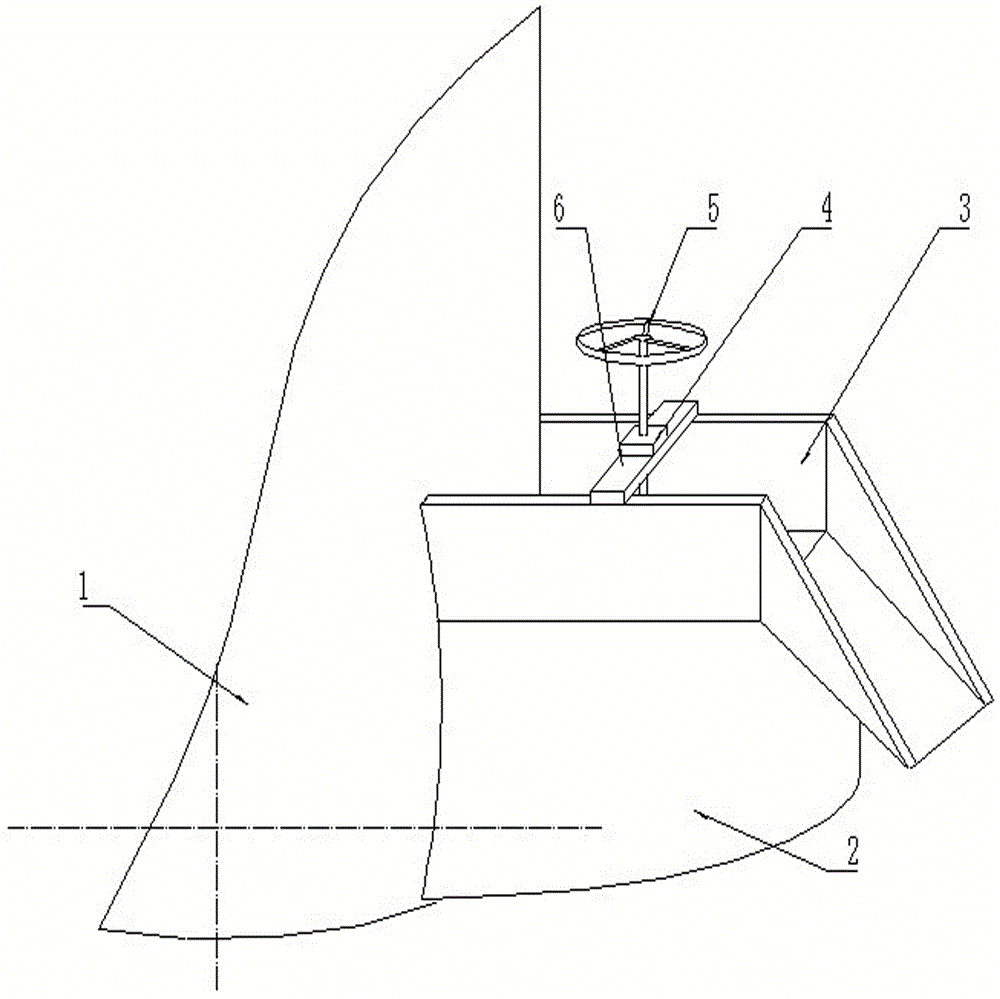

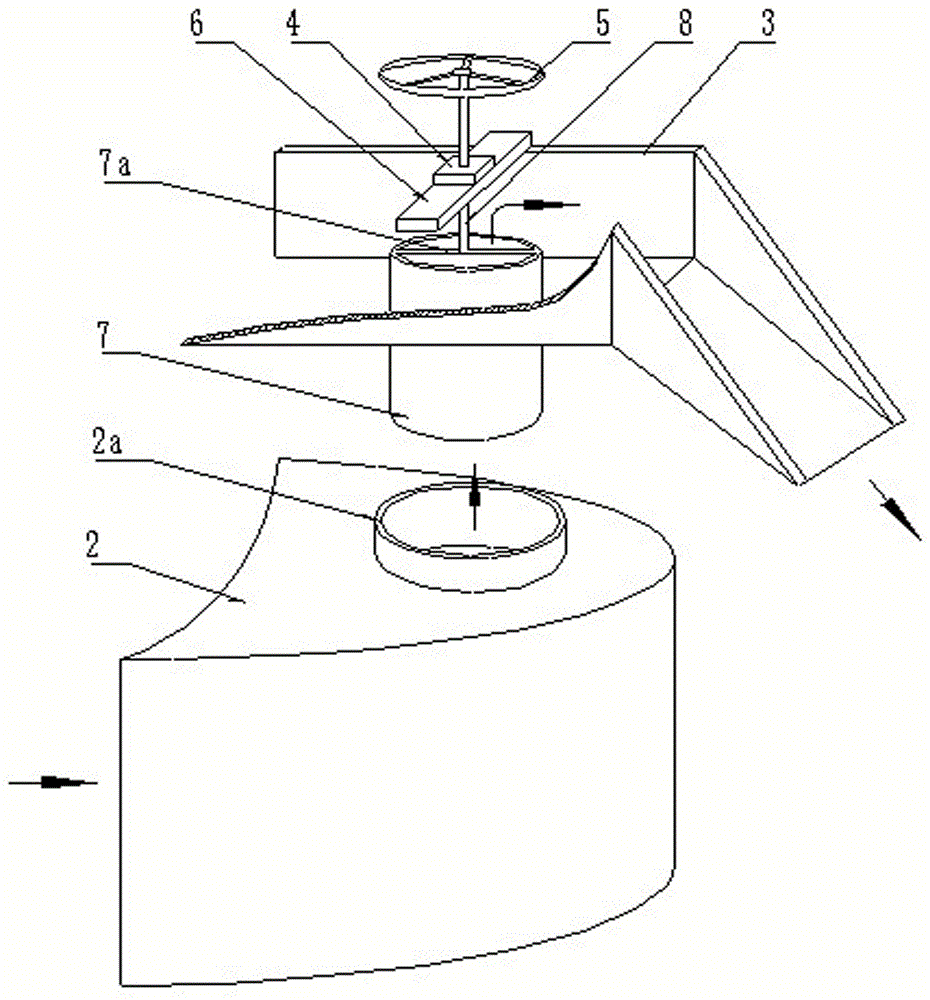

[0010] Such as figure 1 , figure 2 As shown, a desulfurization tower tank tank type liquid level adjustment device of the present invention includes a desulfurization tower 1, a half-drum 2 connected to it is arranged under one side of the desulfurization tower 1, and a half-drum 2 is vertically arranged on the top of the half-drum 2 A casing 2a communicating with it; a drainage groove 3 is arranged above the semi-circular barrel 2, and the top extension section of the casing 2a is arranged in the drainage groove 3; a positioning plate 6 is placed horizontally on the drainage groove 3, and the positioning The plate 6 is provided with a nut 4, the nut 4 is connected with a screw 8, the upper end of the screw 8 is provided with a hand wheel 5, and the lower end of the screw 8 is provided with a cylinder 7; the cylinder 7 is inserted into the sleeve The pipe 2a can also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com