Electrolytic milling tool cathode and method

A technology for processing tools and cathodes, which is applied in the field of electrolytic grinding composite processing, can solve the problems of large overcut, unfavorable electrolytic grinding and milling plane processing, and poor flatness, so as to reduce overcut, eliminate stray corrosion, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

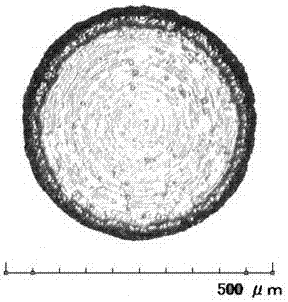

[0029] In this example, the figure 1 As shown in the tool cathode, the bottom end surface of the substrate is flat, and it is not insulated or plated with diamond abrasive grains. from Figure 5It can be seen from the simulated processing section diagram corresponding to the cathode of the tool that the bottom surface of the workpiece is concave, and the center of the bottom surface is the deepest groove, and the connection between the side wall and the bottom surface is arc-shaped. and Figure 7 The actual cross-sectional view of the cathodic electrolytic milling plane groove shown in the tool also shows that the bottom surface of the groove is a concave curved surface, and the depression is the most serious in the middle part. This is because during the processing, the electrolyte flows out from the bottom of the cathode along the opposite direction of feeding at a high speed. With this flow field as the medium, an electric field is formed between the bottom surface of th...

Embodiment 2

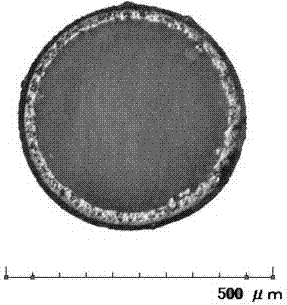

[0031] In this example, the figure 2 For the cathode of the tool shown, a groove with a depth of 0.3mm is completely processed on the bottom end of the substrate, and a waterproof and heat-resistant epoxy resin glue is coated in the groove, and then vacuumized and heat-cured, etc., so that the groove The bonding glue in the groove is closely and firmly combined with the tool cathode, and the bottom surface of the tool cathode is completely insulated at this time. from Figure 5 It can be seen from the simulated processing cross-section diagram corresponding to the cathode of the tool that the bottom surface of the workpiece is convex, and the center of the bottom surface is the shallowest part of the groove. At the same time, the connection between the side wall and the bottom surface is concave, and the connection point is the deepest groove. place. and Figure 8 The actual cross-sectional view of the cathodic electrolytic milling process plane groove shown in the tool al...

Embodiment 3

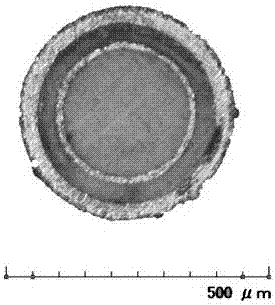

[0033] In this example, the image 3 The schematic diagram of the tool cathode shown in Fig. Figure 4 shown. Two conductive rings are machined on the bottom end of the cathode of the tool with a lathe, wherein the small ring is 0.2 mm wide and the large ring is 0.4 mm wide. The surface of the conductive ring is the bottom surface of the original cathode. The part of the bottom surface other than the conductive ring is a circular groove and an annular groove, both of which have a depth of 0.3mm. Coat waterproof and heat-resistant epoxy resin glue in the groove, and then vacuumize and bake and cure, so that the bonding glue in the groove and the tool cathode are closely and firmly combined. At this time, the bottom surface of the tool cathode is partially insulated. from Figure 5 As can be seen in the simulated processing section shown in the figure, compared with Example 2, the range of the upper convex curve in the middle of the groove bottom of this embodiment is signifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com