Integrated clamping device

A clamp, integrated technology, used in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of limited clamping output torque of eccentric clamping cylinder, inability to achieve self-locking, and long order cycle. , to achieve the effect of fast adjustment, convenient on-site adjustment, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

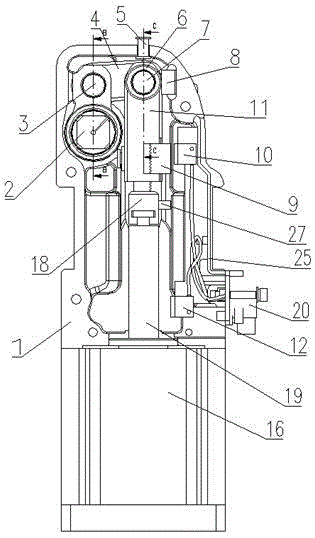

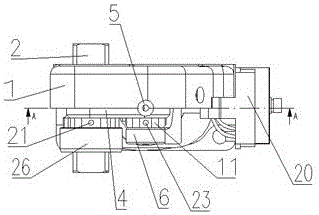

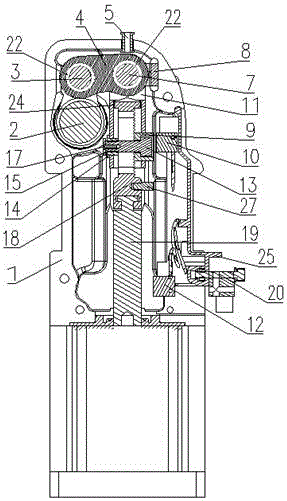

[0021] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

[0022] Such as Figure 1-Figure 5 As shown, an integrated clamp includes a housing 1, a clamping arm rotating part 2, a rotating shaft 3, a connecting rod 4, an auxiliary pin 5, a bearing 6, a rotating shaft 7, and reinforcement Block 8, adjusting stop block 9, clamping in place proximity switch 10, active rod 11, opening in place proximity switch 12, locking bolt 13, T-shaped nut 14, anti-off block 15, cylinder 16, anti-off block fixing bolt 17 , adjusting plate 18, cylinder piston rod 19, proximity switch external connector 20, jackscrew one 21, axle sleeve 22, jackscrew two 23, damping ring 24, proximity switch support 25, bearing two 26 and open inductive block 27 in place.

[0023] The housing 1 is equipped with a cylinder 16, the clamping arm rotating part 2 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com