Disassembling clamping apparatus for valve core of steam intake valve

A spool and valve technology, which is applied in hand-held tools, manufacturing tools, workpiece clamping devices, etc., can solve problems such as difficult disassembly and spool lock, so as to save fixture costs, improve service life and life, and improve The effect of maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0040] Please refer to the attached Figure 2-6 , the embodiment of the present invention provides a professional dismantling fixture for dismantling the steam inlet valve that cannot be repaired due to the locked valve core, including a central rod ( figure 2 ), fixed flange ( image 3 ) and spool wrench ( Figure 4 with Figure 5 ).

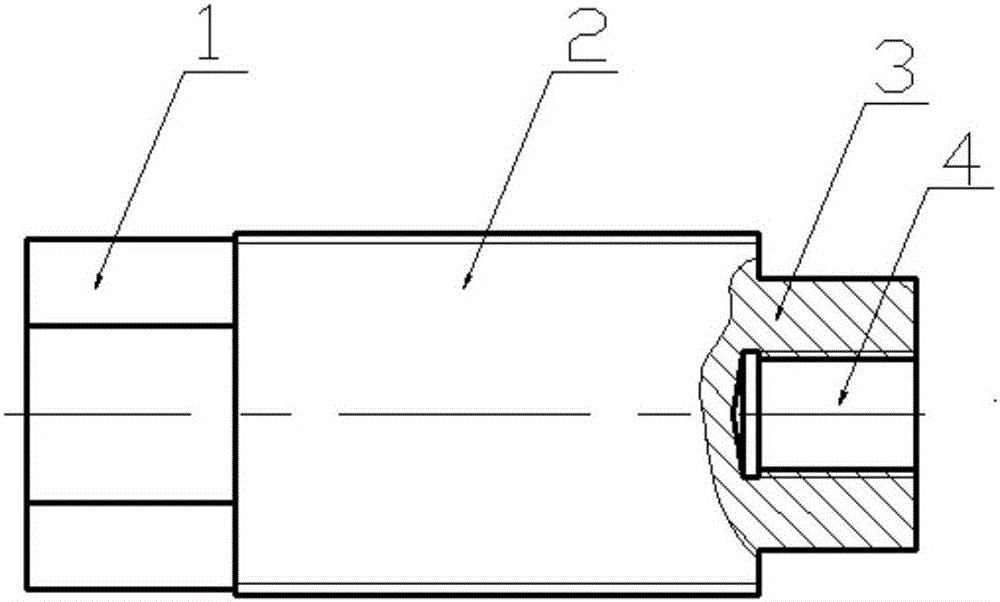

[0041] center pole ( figure 2 ) includes a head structure 1, a central screw 2 and a tail structure 3. The outer circumference of the head structure 1 is a hexagonal structure with a diagonal length of 67mm, which is fixedly connected with the central screw 2, which is convenient to use a percussion wrench to drive the entire central rod to rotate. The tail structure 3 is also fixedly connected with the central screw 2, and the outer circumference of the tail structure 3 is a hexagonal structure with a diagonal length of 52mm.

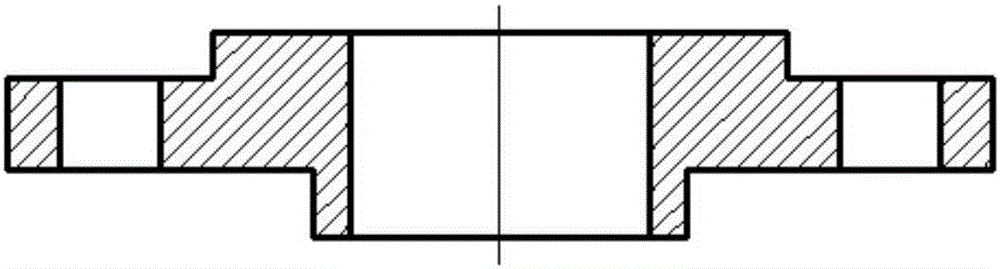

[0042] The outer wall of central screw rod 2 has threads, and the fixed flange ( image 3 ) inner wall also h...

Embodiment approach 2

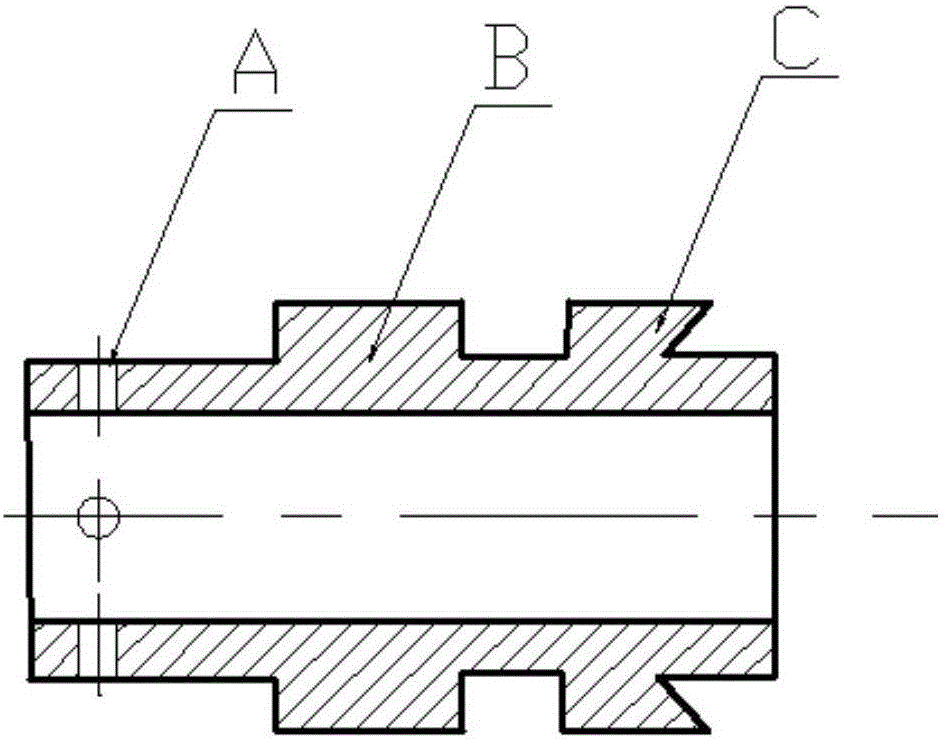

[0054] The difference between this embodiment and Embodiment 1 is that the central rod ( figure 1 ) The outer periphery of the tail structure 3 is a stepped structure, the spool wrench ( Figure 4 with Figure 5 ) is a stepped structure matching the tail structure, the spool wrench is sleeved on the tail structure 3, the stepped structure limits the axial movement of the spool wrench, and other structures, installation methods and working processes are the same.

Embodiment approach 3

[0056] The difference between this embodiment and Embodiment 1 is that the central rod ( figure 1 The outer circumference of the tail structure 3 of ) is circular, the outer wall is provided with external threads opposite to the thread direction of the central screw rod 2, and the inner wall of the center through hole of the valve core wrench is provided with internal threads matching the outer wall threads of the tail structure. The spool wrench is connected with the tail structure of the center rod by threads. This embodiment does not need fixing parts, and the center of the tail structure does not need to be provided with an installation hole, and other structures, installation methods, and working processes are the same as Embodiment 1.

[0057] From the above it can be seen that:

[0058] (1) The dismantling fixture of the present invention can fix the fixture on the steam inlet valve through the fixing flange. Since the center rod and the fixing flange are connected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com