Single-motor synchronous double-driving device for driving friction lever

A motor-driven, friction rod technology, used in transmission parts, conveyors, mechanical equipment, etc., can solve problems such as motor damage, friction rods are easy to collide, and structural performance is degraded, so as to prevent motor damage, run smoothly, and prevent The effect of structural performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

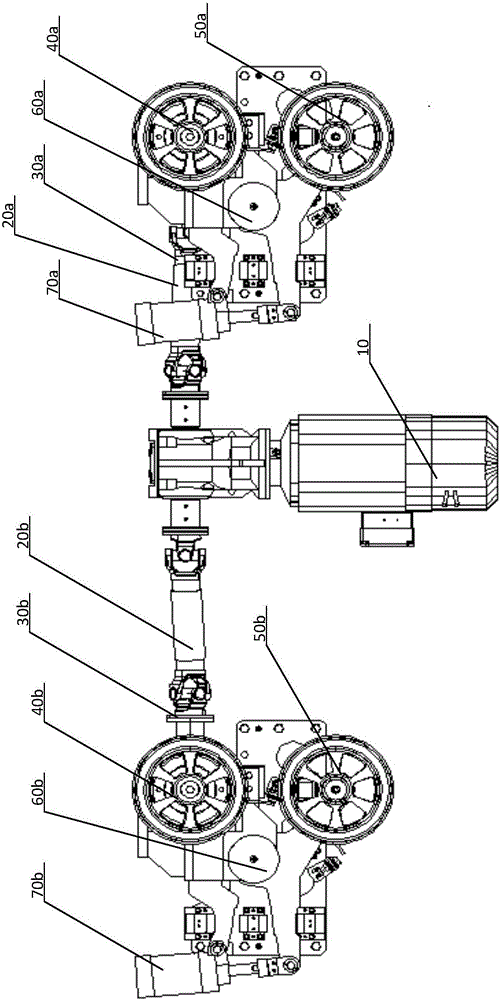

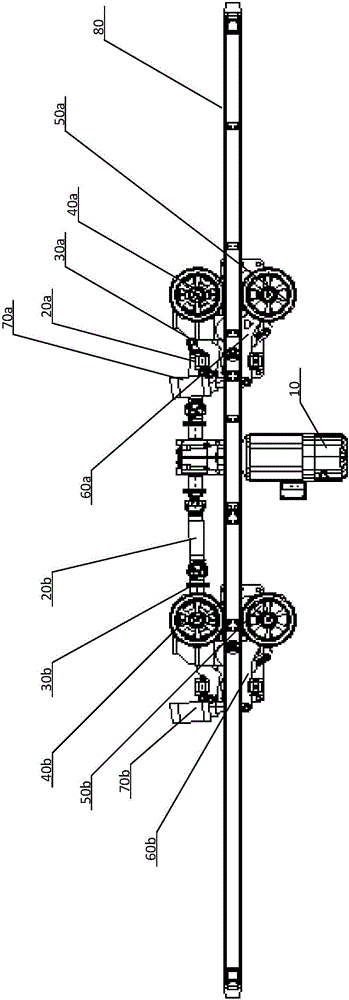

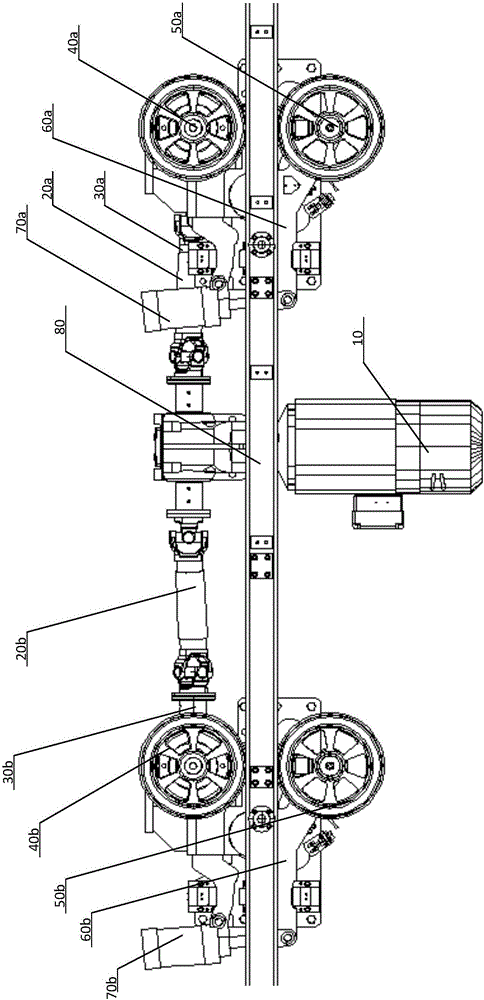

[0017] Such as figure 1 with 2 As shown, the single-motor synchronous dual-drive device for driving the friction rod of the present invention mainly consists of a motor 10, a pair of couplings 20a and 20b, a pair of single-stage reducers 30a and 30b, a pair of active rubber wheels 40a and 40b, a pair of driven rubber wheels 50a and 50b, a pair of scissor arms 60a and 60b, a pair of air cylinders 70a and 70b, and a friction rod 80. The motor 10 is arranged in the middle position of the single-motor synchronous dual-drive device.

[0018] A pair of active rubber wheels 40a, 40b are respectively located at the two ends of the friction rod 80, and the couplings 20a, 20b and single-stage reducers 30a, 30b are arranged between the motor 10 and the active rubber wheels 40a, 40b to facilitate The torque of the motor 10 is transmitted to the active rubber wheels 40a, 40b by the couplings 20a, 20b, and the speed is adjusted to the required working speed of the active rubber wheels 40a, 40b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com