Intelligent handling line

A transfer line and linear technology, applied in the field of transfer line, can solve the problems of large manpower consumption, high production cost, high risk, etc., and achieve the effect of improving work efficiency, easy operation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The preferred embodiments of the present invention will be described in detail below with reference to the drawings.

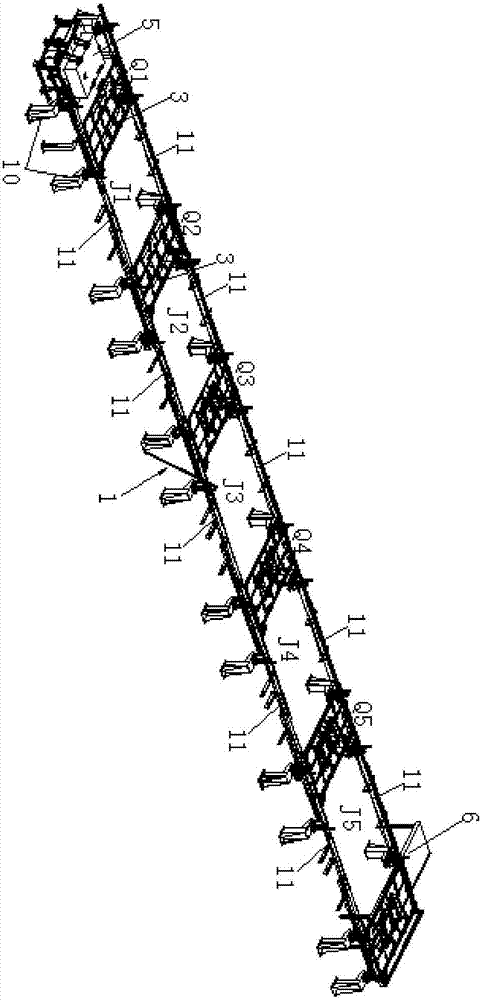

[0052] The invention provides an intelligent handling line, wherein a plurality of processing stations are arranged linearly, and the intelligent handling line cooperates and runs through the plurality of processing stations, and is used to transport the workpiece to be processed to each processing station for each processing. This intelligent handling line includes a wire body frame and a plurality of reclaiming trolleys 3 for reclaiming materials, wherein the wire body frame includes a lifting device 1, and is arranged horizontally side by side on the lifting device. The two linear tracks 2 on the It is bridged between the two linear rails 2 , and the multiple reclaiming trolleys 3 are also capable of reciprocating positioning along the length direction of the linear rails 2 .

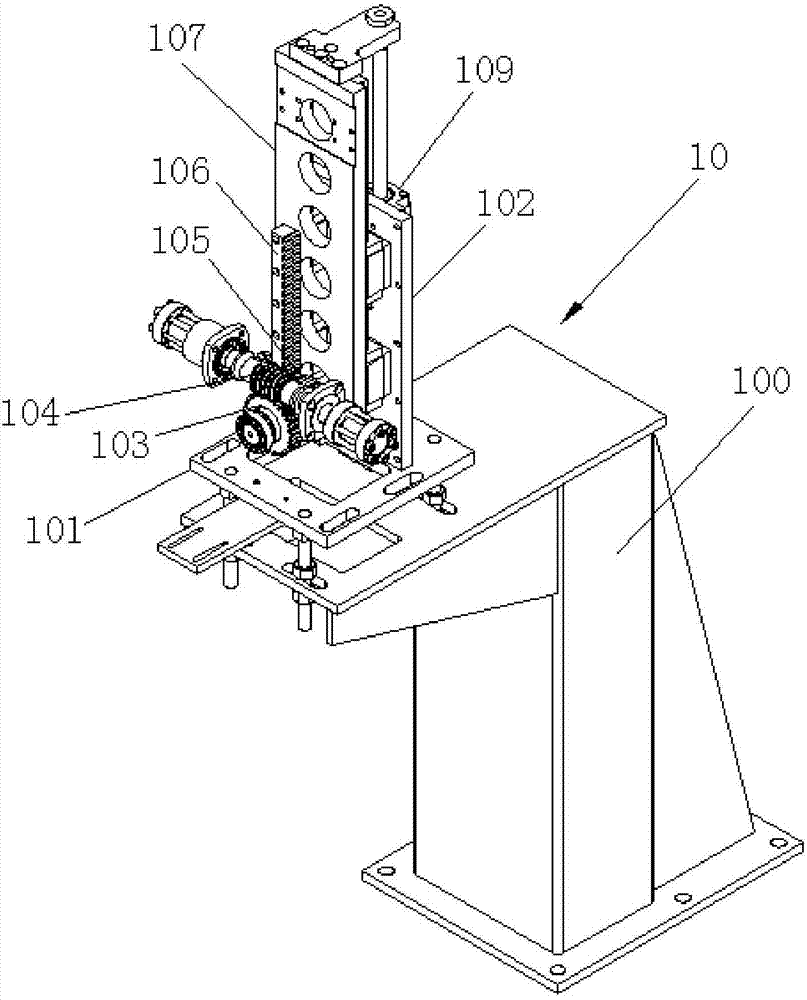

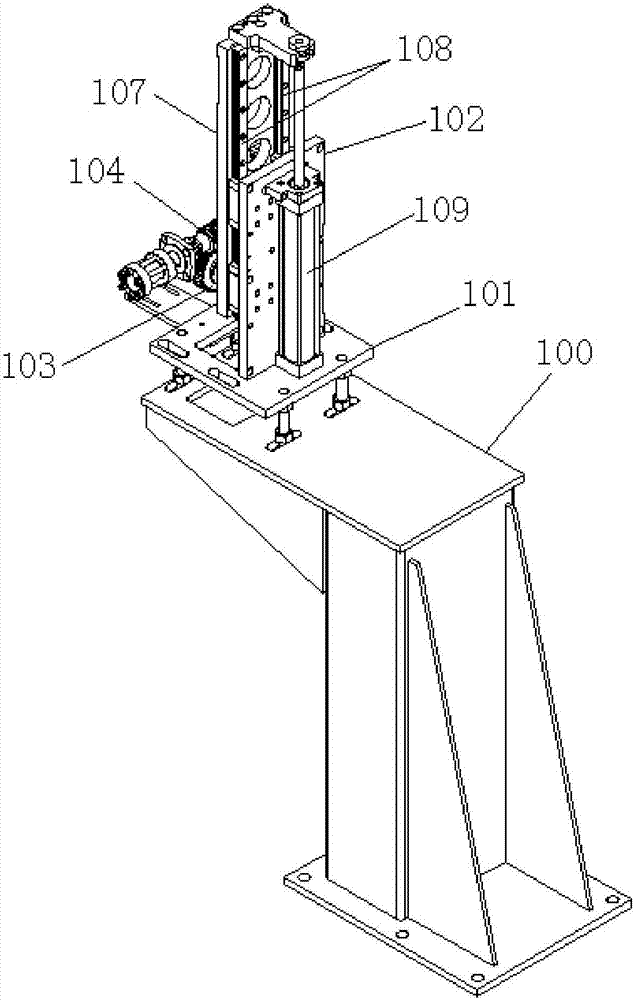

[0053] In this embodiment, the lifting device 1 includes two groups of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com