Third-generation pneumatic tank curtain door automatic system

An automation system, the technology of tank curtain door, applied in the direction of lifting equipment, transportation and packaging in mines, can solve the problems of slow operation speed, personnel injury, poor coordination between hook workers and signal workers, etc., to achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

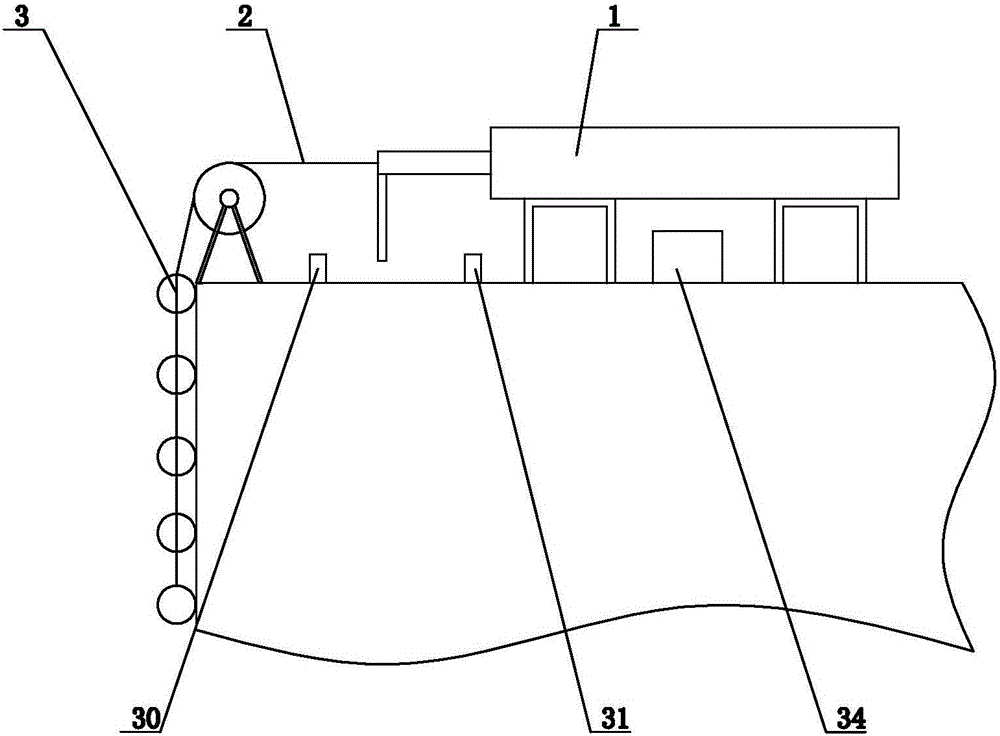

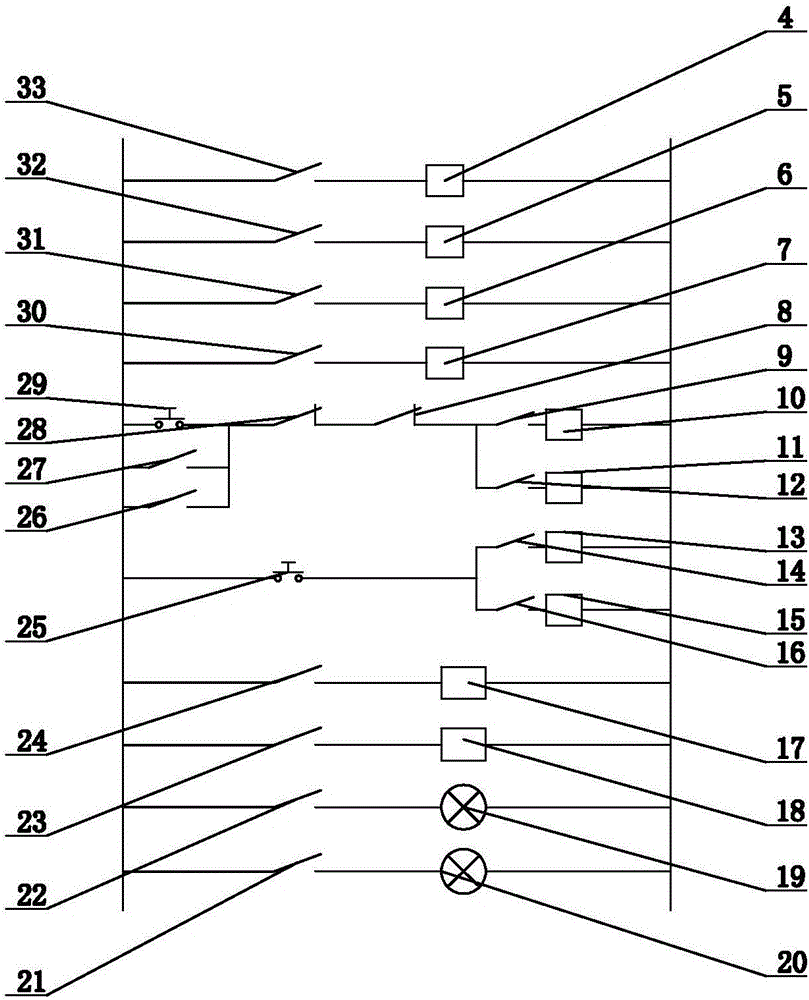

[0012] like figure 1 and figure 2 As shown in the figure, the third-generation pneumatic tank shutter automation system of the present invention includes a tank shutter 3, the steel wire 2 of the tank shutter 3 is connected to the cylinder 1 through a pulley, and the air chamber of the cylinder 1 is connected to the high-pressure gas through a solenoid valve. The source, the piston rod of the cylinder 1 is provided with a trigger device, and the travel track of the trigger device is provided with a travel switch A31 and a travel switch B30 respectively. One end of the travel switch A31 and the travel switch B30 is connected to the power supply, and the other end is connected to the control device 34 . Through the expansion and contraction of the cylinder 1, the steel wire is pulled to make the tank shutter 3 retractable up and down. The travel switch A31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com