Near zero emission treatment process for flue gas desulfurization waste water

A desulfurization wastewater, near-zero discharge technology, applied in the direction of gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of unstable effluent water quality, inability to effectively remove dissolved inorganic salts, etc., to achieve The effect of resource utilization, reduction of turbidity and silting index, and improvement of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific embodiment:

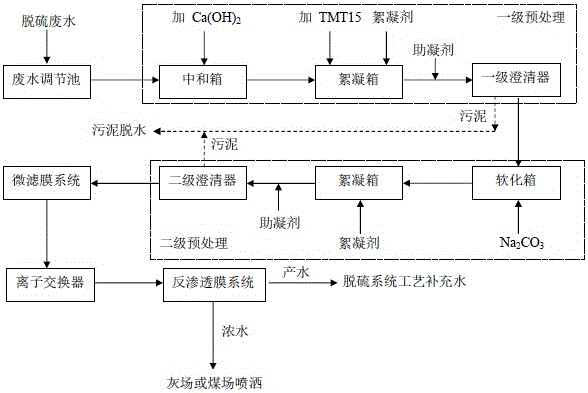

[0033] Such as figure 1 As shown, the near-zero discharge treatment process of flue gas desulfurization wastewater, the process flow is as follows:

[0034] The waste water from flue gas desulfurization is collected into the waste water regulating tank for water volume regulation and water quality homogenization to reduce system fluctuations and ensure the normal operation of subsequent equipment. The pH value of weakly acidic desulfurization wastewater is adjusted to 9.0~9.5, and after precipitation, flocculation, clarification and other processes, most of the Mg contained in the wastewater 2+ , heavy metal ions, F - , suspended solids and colloids are removed; the primary effluent is sent to the secondary pretreatment system, according to the concentration of calcium and magnesium ions in the water, according to the relationship of molar ratio 1:1, an appropriate amount ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap