Activated sludge stabilizing treatment method for sewage treatment

A technology for activated sludge and sewage treatment, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc. Achieve the effect of eliminating hidden safety hazards, no secondary pollution, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

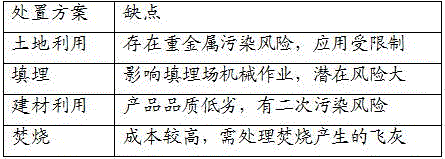

Problems solved by technology

Method used

Image

Examples

Example Embodiment

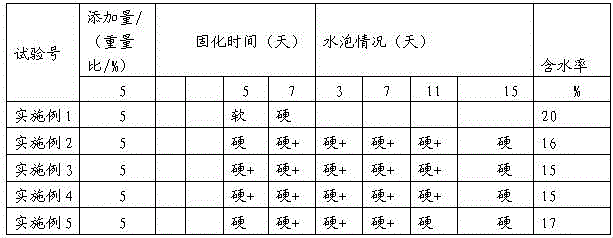

[0027] Example 1

[0028] A method for stabilizing activated sludge for sewage treatment, adding a curing agent to the dewatered sludge of a sewage treatment plant, stirring the reaction, and drying after the reaction, and then landfilling;

[0029] The curing agent is composed of the following components by weight: 15% fly ash, 35% quicklime, 25% plaster of paris, 5% ferric chloride, 5% sulfate and 0.5% cationic polyacrylamide.

Example Embodiment

[0030] Example 2

[0031] A method for stabilizing activated sludge for sewage treatment, adding a curing agent to the dewatered sludge of a sewage treatment plant, stirring the reaction, and drying after the reaction, and then landfilling;

[0032] The curing agent is composed of the following components by weight: 25% fly ash, 45% quicklime, 40% plaster of paris, 10% ferric chloride, 10% sulfate and 2% cationic polyacrylamide.

[0033] The effective content of calcium oxide in the quicklime is 75%.

Example Embodiment

[0034] Example 3

[0035] A method for stabilizing activated sludge for sewage treatment, adding a curing agent to the dewatered sludge of a sewage treatment plant, stirring the reaction, and drying after the reaction, and then landfilling;

[0036] The curing agent is composed of the following components by weight: 20% fly ash, 40% quicklime, 30% plaster of paris, 6% ferric chloride, 6% ferrous sulfate and 0.8% cationic polyacrylamide.

[0037] After the reaction is over, the sludge is made into a rectangular block solid of 40 cm×30 cm×30 cm, and then air-dried naturally for 7 days.

[0038] The effective content of calcium oxide in the quicklime is 70%.

[0039] The added amount of the curing agent is 5% of the mass of the sludge.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap