A kind of antibacterial plastic and preparation method thereof

A technology for antibacterial plastics and raw materials, applied in the field of antibacterial plastics and their preparation, can solve the problems of high toxicity to the human body, poor temperature resistance, environmental pollution, etc., and achieve the effects of small particle size, strong antibacterial performance and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

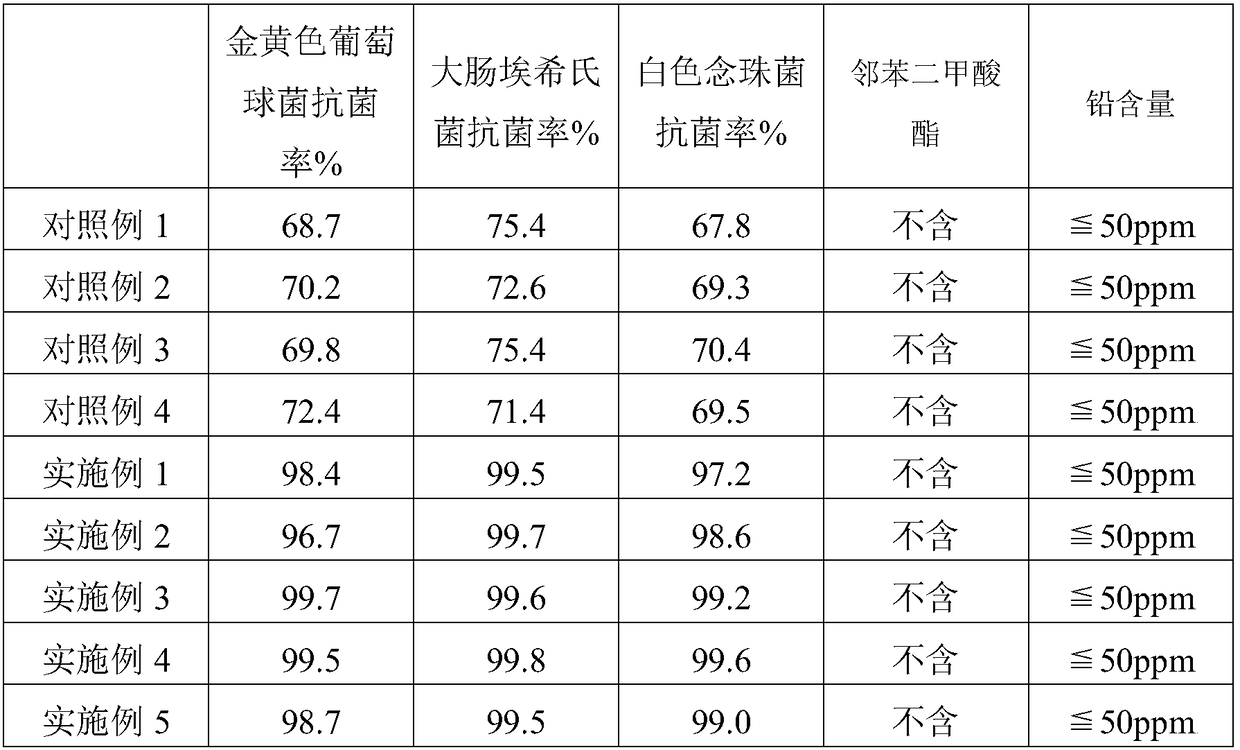

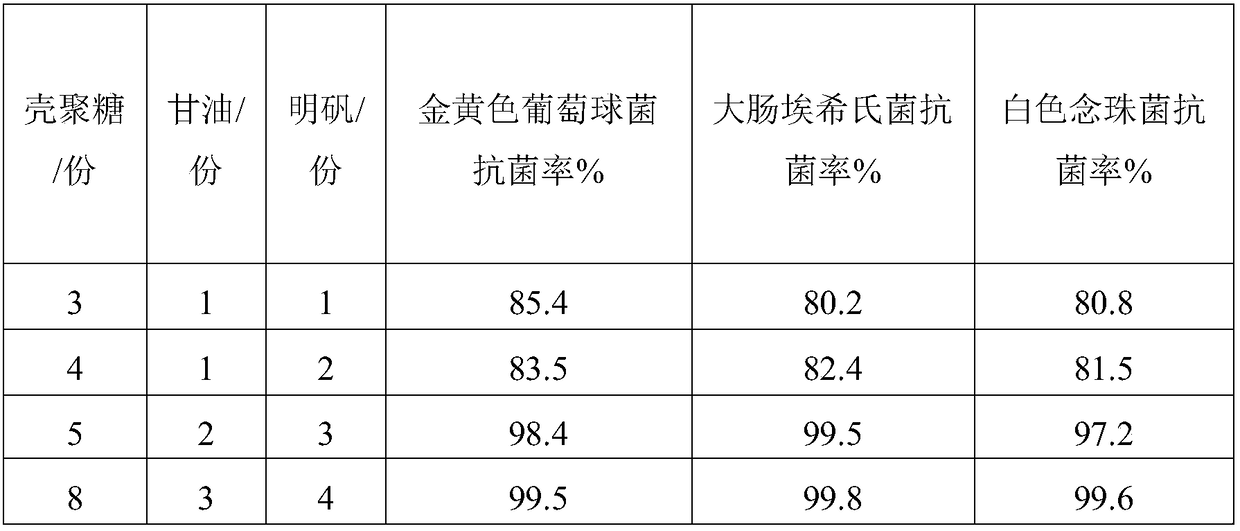

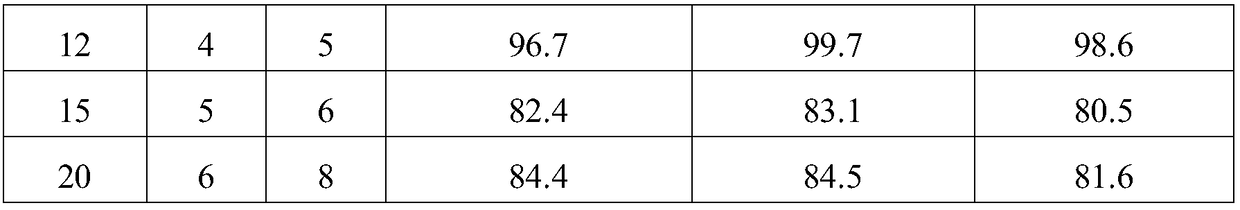

Examples

Embodiment 1

[0016] An antibacterial plastic, the components are as follows:

[0017] 25 parts of high-density polyethylene, 10 parts of hydroxyapatite, 5 parts of chitosan, 4 parts of ammonium dihydrogen phosphate, 20 parts of ABS resin, 1 part of antioxidant 168, 2 parts of glycerin, and 3 parts of alum.

[0018] Preparation:

[0019] (1) Take high-density polyethylene, hydroxyapatite, ammonium dihydrogen phosphate, ABS resin, alum by parts by weight, mechanically mix, cross 100 mesh sieves;

[0020] (2) Stir the mixed material in a high-speed mixer at 120° C. for 15 minutes, and add chitosan, antioxidant, glycerin and water 1.5 times the weight of the material after mixing;

[0021] (3) After the stirred material is passed through a 150-mesh sieve, it is sent to a twin-screw extruder for extrusion, and after pelletizing, it is cooled to make an antibacterial plastic.

Embodiment 2

[0023] An antibacterial plastic, the components are as follows:

[0024] 38 parts of high-density polyethylene, 15 parts of hydroxyapatite, 12 parts of chitosan, 7 parts of ammonium dihydrogen phosphate, 32 parts of ABS resin, 3 parts of antioxidant 164, 4 parts of glycerin, and 5 parts of alum.

[0025] Preparation:

[0026] (1) Take high-density polyethylene, hydroxyapatite, ammonium dihydrogen phosphate, ABS resin, alum by parts by weight, mechanically mix, cross 150 mesh sieves;

[0027] (2) Stir the mixed material in a high-speed mixer at 150° C. for 10 minutes, and add chitosan, antioxidant, glycerin and water twice the weight of the mixed material during stirring;

[0028] (3) After the stirred material is passed through a 200-mesh sieve, it is sent to a twin-screw extruder for extrusion, and after pelletizing, it is cooled to make an antibacterial plastic.

Embodiment 3

[0030] An antibacterial plastic, the components are as follows:

[0031] 32 parts of high-density polyethylene, 13 parts of hydroxyapatite, 9 parts of chitosan, 5 parts of ammonium dihydrogen phosphate, 26 parts of ABS resin, 2 parts of antioxidant 168, 3 parts of glycerin, and 4 parts of alum.

[0032] Preparation:

[0033] (1) Take high-density polyethylene, hydroxyapatite, ammonium dihydrogen phosphate, ABS resin, alum by parts by weight, mechanically mix, cross 125 mesh sieves;

[0034] (2) Stir the mixed material in a high-speed mixer at 135° C. for 13 minutes, and add chitosan, antioxidant, glycerin and water 1.8 times the weight of the mixed material in an appropriate amount;

[0035] (3) After the stirred material is passed through a 175 mesh sieve, it is sent to a twin-screw extruder for extrusion, pelletized and then cooled to make an antibacterial plastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com