A composite ald air guiding device

An air guide and composite technology, which is applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of uneven film preparation, and achieve the effects of improving uniformity, improving airflow distribution, and saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

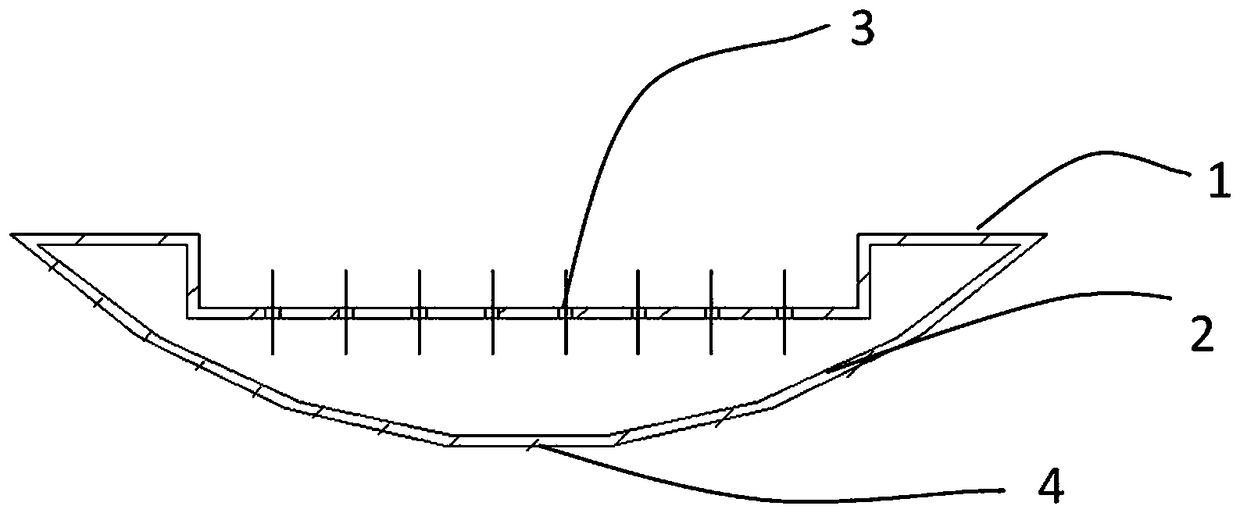

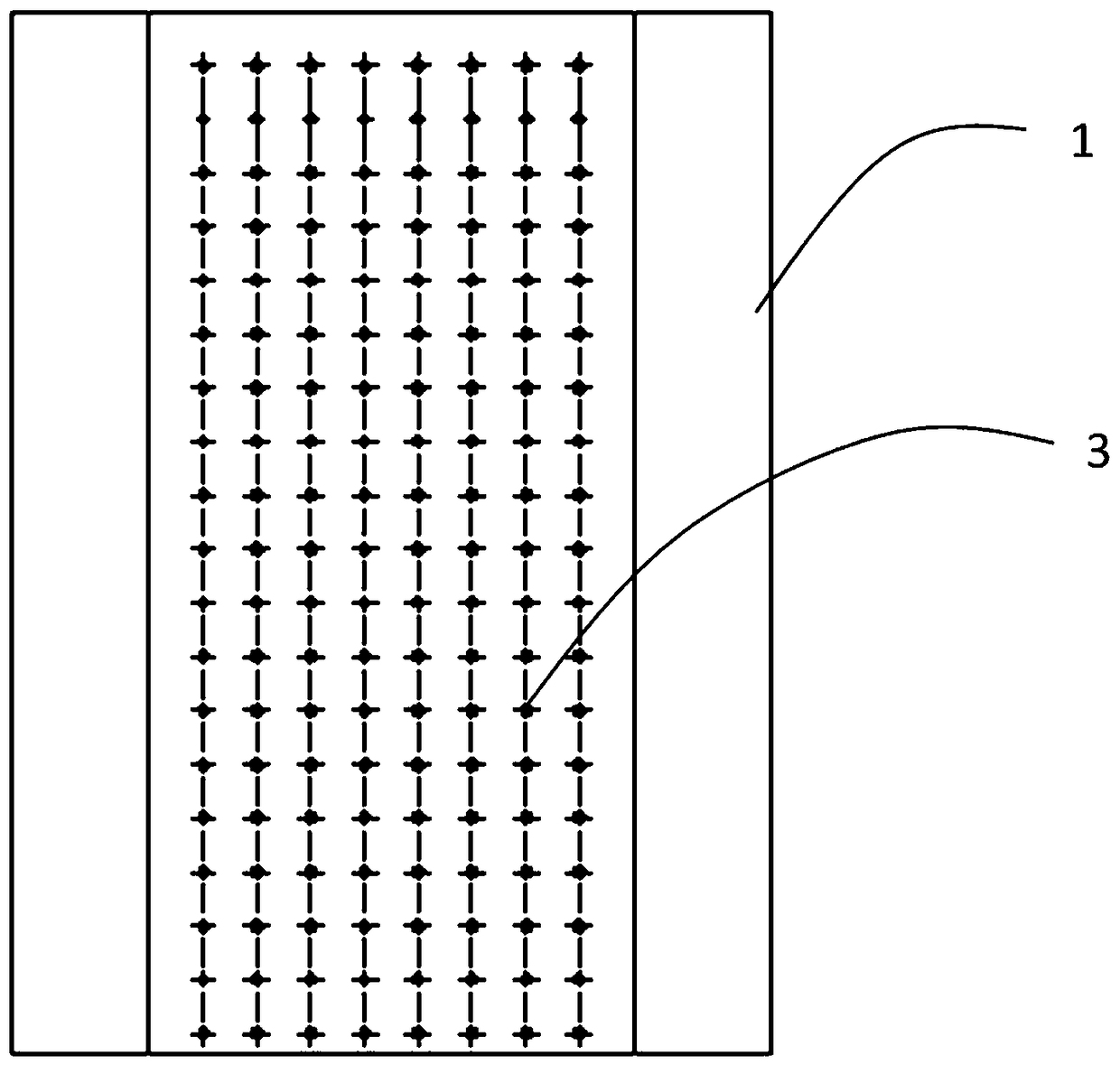

[0020] Such as figure 1 , and 2 are structural schematic diagrams of a preferred embodiment of the present invention. The composite ALD air guide device includes a main structure composed of a plane step (1) and an arc wall (2), and a guide The air hole array (3) and the air extraction hole (4). Plane steps (1), the middle part is used to arrange air guide holes, and the platforms on both sides are used to install sample holders in the chamber; the arc wall (2), whose radian is the same as that of the reaction chamber, is easy to install on the inner wall of the reaction chamber; the air guide hole array ( 3), the holes run through in the vertical direction, the hole diameter is 1-3mm, and they are evenly distributed in a rectangular shape. The hole spacing is 10mm~50mm, and they are connected with the inside of the device and the pumping holes, used for diversion during the gas pumping process, and optimize the cavity Airflow distribution; the air extraction hole (4), connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com