Steel box buckle cap temporary construction road

A steel, box-body technology, applied in the direction of roads, roads, special pavements, etc., can solve the problems of difficult turnover, high site requirements, waste of resources and the environment, etc., to achieve strong coping ability, low site requirements, and quick assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

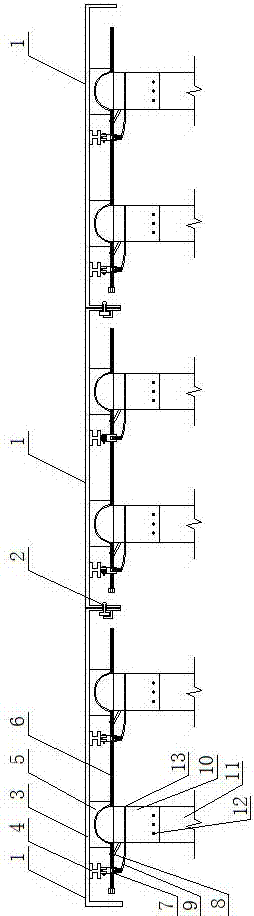

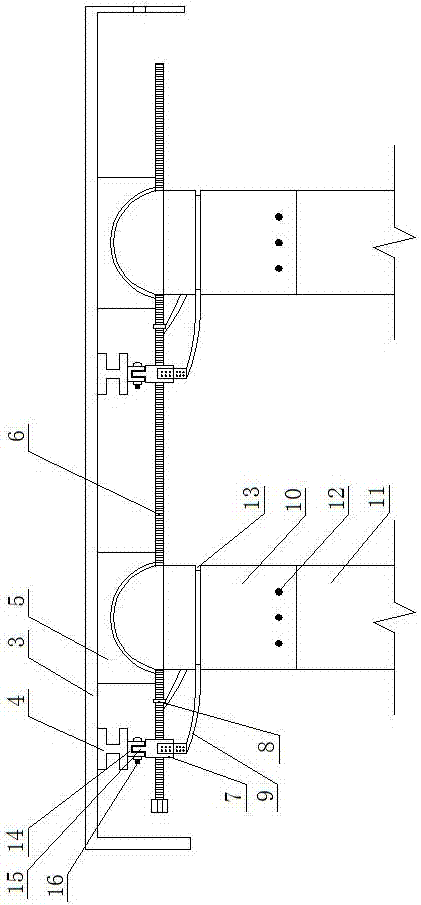

[0028] Such as figure 1 As shown in -6, the temporary construction road of the steel box buckle cap type includes several sets of box assemblies 1 arranged in sequence, and two adjacent sets of box assemblies 1 are connected by connectors 2 .

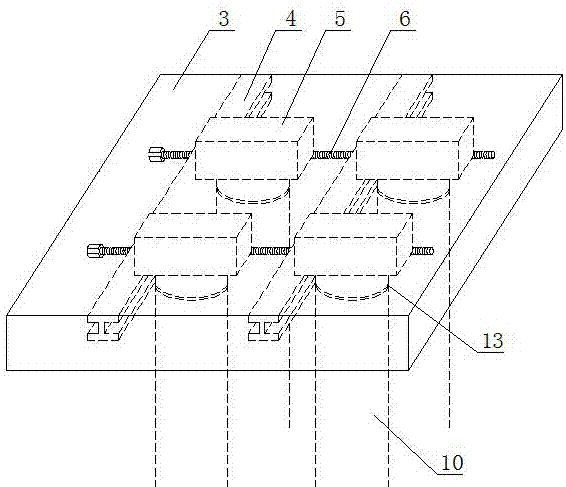

[0029] Each box assembly 1 includes a rectangular steel box 3 with an open lower end, two I-beams 4, two screw rods 6, four steel buckle caps 5, four steel fasteners 7, and four baffles 8 And four steel bands 9, four vertically arranged sleeves 10 and four vertically arranged fixed piles 11. Two I-beams 4 and four steel buckle caps 5 are welded on the inner top of the steel plate box body 3, the two I-beams 4 are arranged vertically, and the four steel buckle caps 5 are arranged in two rows and two columns, located in the vertical Two of the steel buckle caps 5 are arranged on one side of one I-beam 4 , and the other two steel buckle caps 5 positioned in the longitudinal direction are arranged on one side of another I-beam 4 . The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com