External Prestressed Strengthening Structure and Method of Concrete T Beam

A technology of external prestressing and strengthening structures, which is applied in bridge reinforcement, bridges, bridge materials, etc., can solve the problems of reducing the durability of steel strands, expensive FRP bars, and complicated construction processes, so as to improve bearing capacity and durability , good reinforcement effect and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

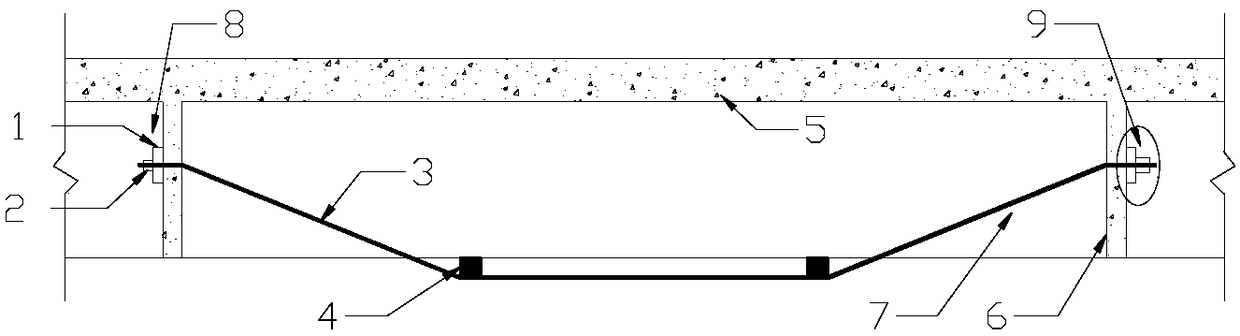

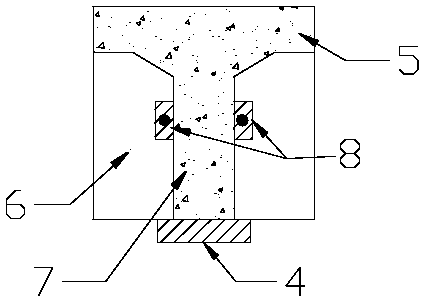

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

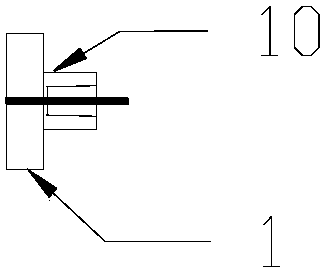

[0030] see Figure 1 to Figure 3 The reinforcement structure of the present invention includes several vertical diaphragms 6 arranged side by side on the lower side of the concrete T beam flange 5; the bottom of the concrete T beam web 7 is provided with a pair of horizontal support pads 4, and each pair of support pads The plates 4 are all located between two adjacent diaphragms 6; one end of the high-strength aluminum alloy rib 3 is respectively fixed on the diaphragm 6, and one end of the high-strength aluminum alloy rib 3 passes through the diaphragm 6 and passes through the end plate 1 and aluminum alloy bolts 2 for anchoring to form the anchor end 8; the other end of the high-strength aluminum alloy bars 3 passes through the diaphragm 6, and through the end backing plate 1 and the wedge-shaped clip-type anchor 10 through the core-type jack Anchored by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com