Axial-flow compressor rotor with flow-guiding small blades

An axial flow compressor and small vane technology, which is applied to the components of the pumping device for elastic fluids, mechanical equipment, machines/engines, etc. Convenience and the effect of improving the flow margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with specific implementation examples.

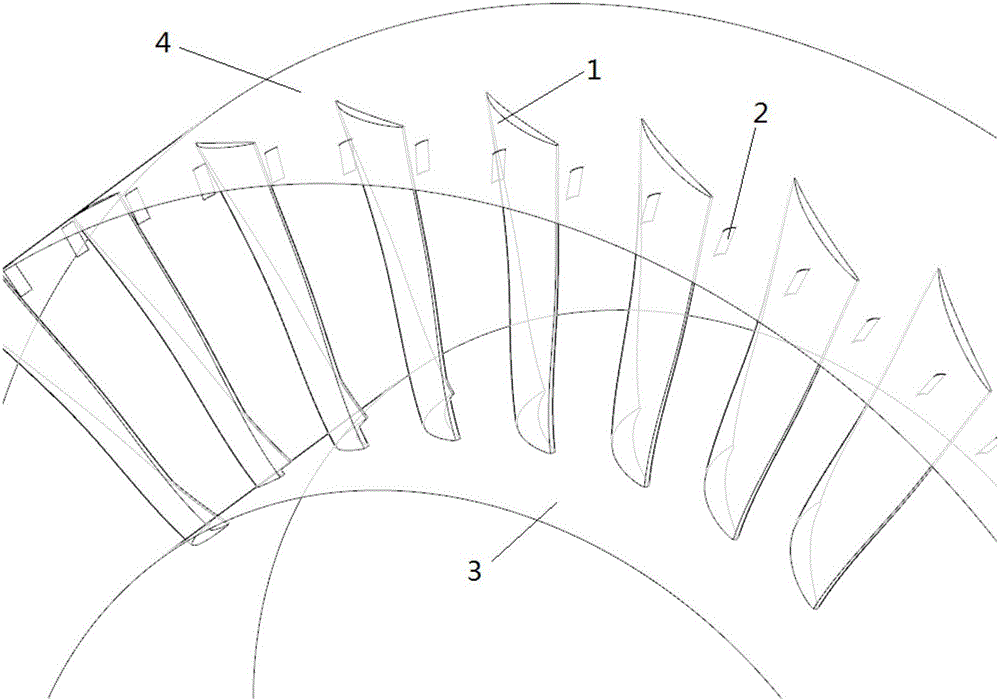

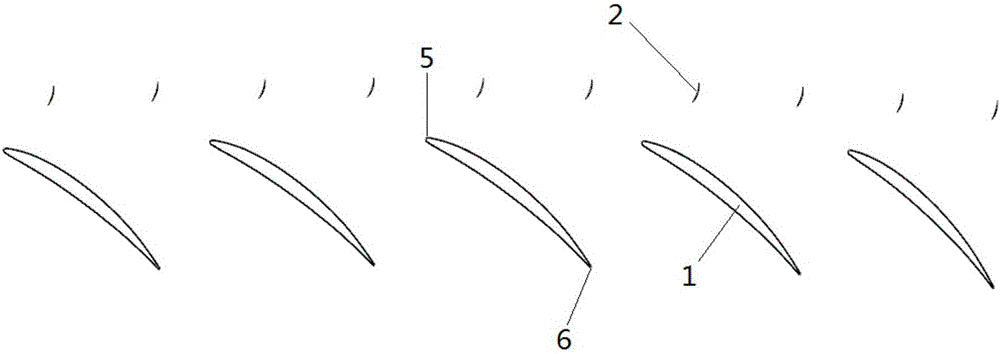

[0014] 1. See Figure 1-Figure 3 , an axial flow compressor rotor with guide vanes, including axial compressor rotor blades, axial compressor hub, casing and guide vanes, which is characterized in that the guide vanes are installed on the rotor blades On the casing upstream of the top channel, the chord length of the small blade is 1-2 orders of magnitude lower than that of the rotor blade, that is to say, the chord length is 1%-20% of the rotor blade, and the height is 5%-15% of the rotor blade height. Evenly distributed on the casing in the circumferential direction, the number is 1-2 times the number of rotor blades, and the axial position is located at 10%-30% of the blade tip chord length upstream of the blade tip passage. The small blade root is welded on the casing.

[0015] The small blades are straight blades with a pair of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com