Light Emitting Device

A technology for light-emitting devices and light-emitting elements, which is applied to signal devices, lighting devices, light sources, etc., can solve the problems of poor light distribution, poor curing efficiency, and poor light distribution of light-emitting devices, so as to improve peak illuminance, improve light distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

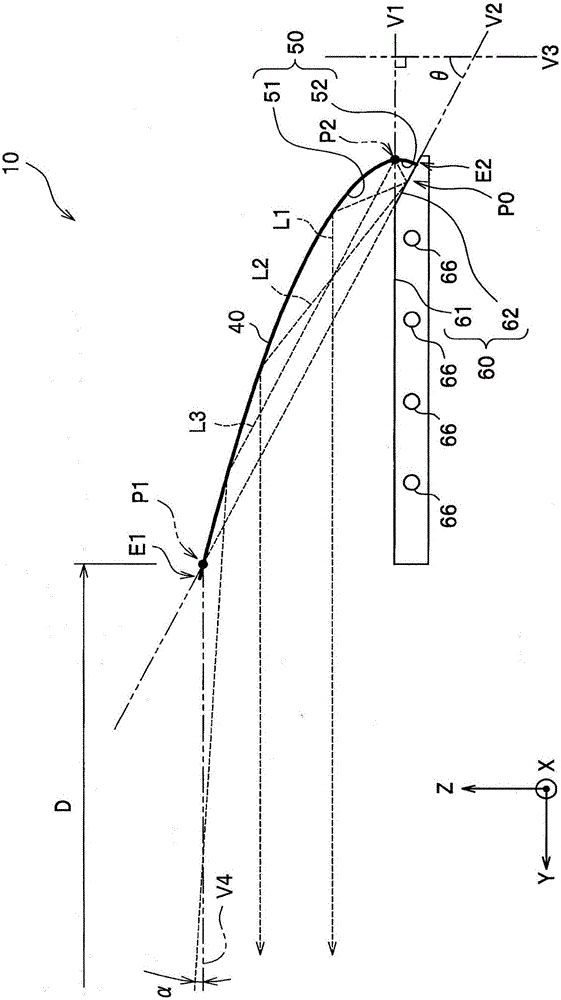

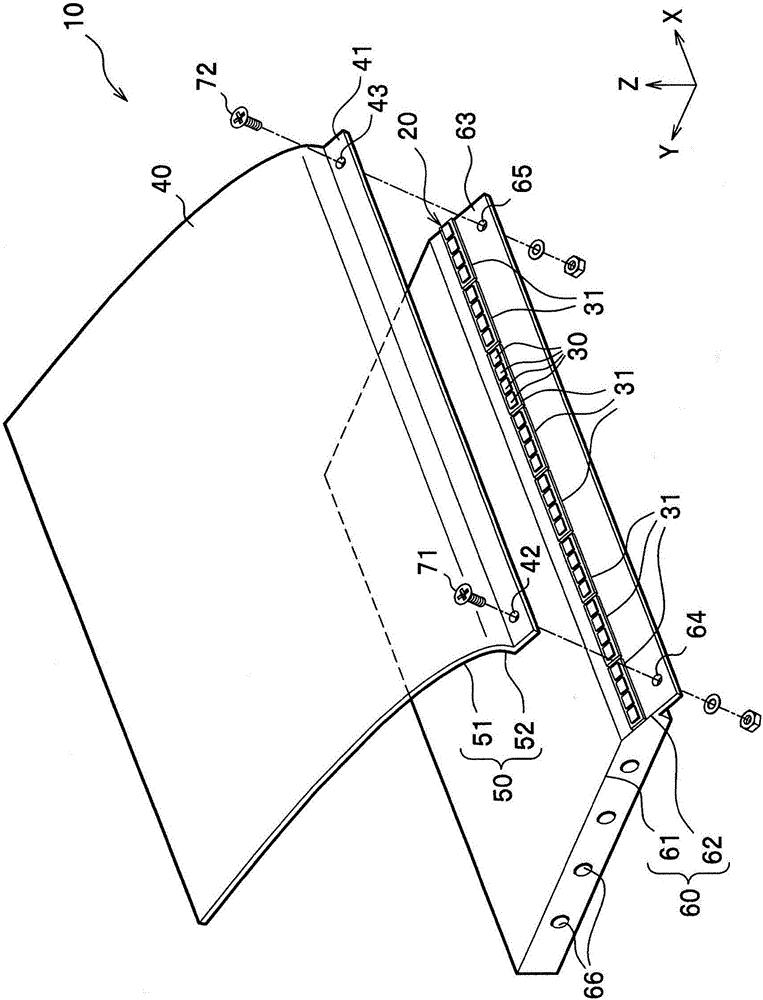

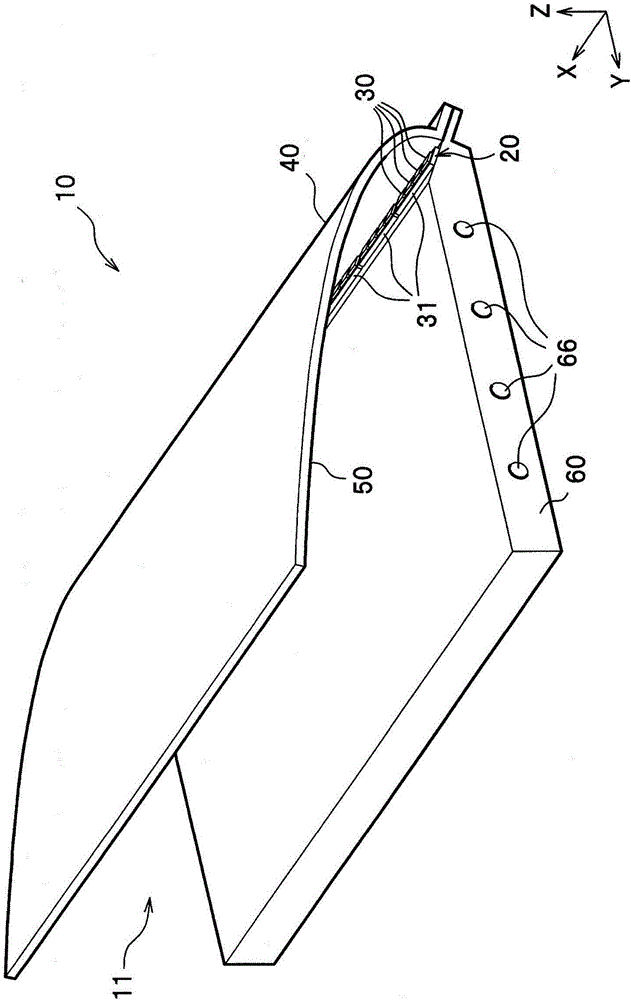

[0046] Hereinafter, an ultraviolet irradiation device for curing ink and the like will be described as an example of the light emitting device according to the first embodiment of the present invention. Such as Figure 1 to Figure 3 As shown, the light emitting device 10 of this embodiment mainly includes a light source unit 20 , a reflection unit 40 , and an installation stand 60 . Such as image 3 As shown, the light-emitting device 10 connects the reflector 40 and the installation platform 60 on the side opposite to the light irradiation direction side, and has an opening 11 formed by separating the reflection unit 40 from the installation platform 60 on the light irradiation direction side. The light emitting device 10 emits light (ultraviolet light) in the horizontal direction toward an irradiation surface that is an object separated by a predetermined distance (for example, 10 mm or more).

[0047] Hereinafter, the extending direction of the linear light source unit 20...

no. 2 approach

[0083] Figure 4 The light emitting device 10A shown with figure 2 The light emitting device 10 shown is different in that a plurality of light emitting elements 30 are arranged in two rows on the light source portion 20A. Therefore, for figure 2The same structures of the light emitting device 10 shown are denoted by the same reference numerals, and description thereof will be omitted.

[0084] The light source unit 20A includes a first light source unit 21 and a second light source unit 22 .

[0085] The first light source unit 21 is a light source unit in which a plurality of light emitting elements 30 are linearly arranged in the X direction.

[0086] The second light source unit 22 is a light source unit in which a plurality of light emitting elements 30 are linearly arranged parallel to the first light source unit 21 . The second light source unit 22 is disposed close to the first light source unit 21 .

[0087] More specifically, the first light source unit 21 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com