Torch connector

A technology for connecting heads and torches, which is applied in the field of hardware parts, can solve the problems of easy slippage and displacement of torch heads, easy to drop off glue, easy to produce peculiar smell, etc., and achieve the effect of convenient packaging and transportation process, firm positioning, and convenient connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

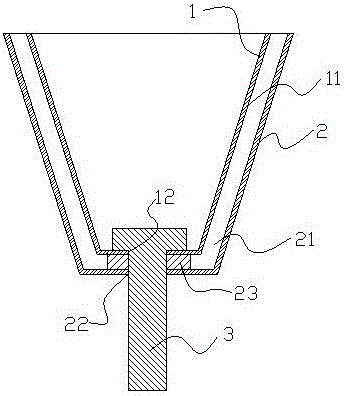

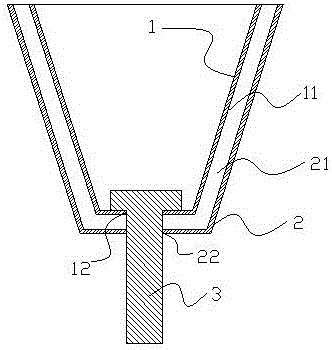

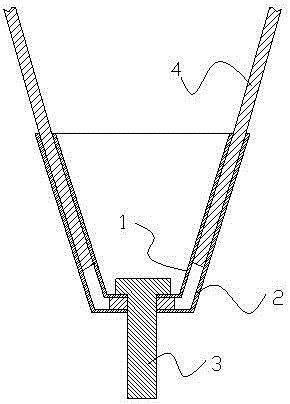

Embodiment 1

[0017] A positioning nut 23 is connected to the fixing hole 22 of the outer connecting portion 2 . In this way, even after the torch head 4 and the torch rod 5 are disassembled and separated, the outer connecting portion 2 is still connected to the connecting screw 3, thereby enhancing the stability of the structure. The connecting screw 3 is fixedly connected with the inner connecting part 1, which further enhances the stability of the structure. During use, the connecting screw rod 3 is aligned and screwed into the positioning nut 23, so that the arc surface 11 of the inner connecting part 1 and the surrounding wall of the inner cavity 21 of the outer connecting part 2 clamp the root of the torch head 4 and get final product. When finally assembling, align the root of the connecting screw 3 with the mounting screw hole screwed into the torch bar 5 to get final product. Both the inner connection part 1 and the outer connection part 2 of this embodiment can be made by punchin...

Embodiment 2

[0019] Different from Embodiment 1, the outer connection part 2 is provided with an internal thread in the fixing hole 22, and the fixing hole 12 of the inner connection part 1 is also provided with an internal thread, so that the connection between the inner connection part 1 and the outer connection part 1 can be ensured directly through the connecting screw 3. The stability of the connection part 2. Tightening the connecting screw 3 can make the arc surface 11 of the inner connecting part 1 and the peripheral wall of the inner chamber 21 of the outer connecting part 2 clamp the root of the torch head 4, and the installation is simple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com