Efficient lifting device for yarn drying

A high-efficiency, yarn-based technology, applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problem that the production efficiency cannot be effectively improved, the heat energy cannot be used well, and the yarn does not have any help, etc. problem, to achieve the effect of simple structure, good drying consistency, and reduced heat waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

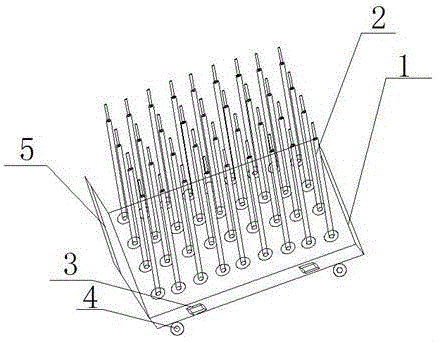

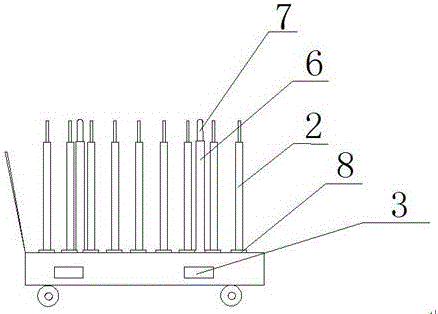

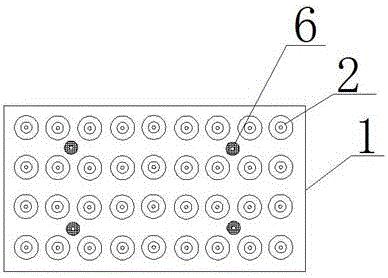

[0018] Such as Figure 1~4 As shown, a high-efficiency lifting device for yarn drying includes a base 1, a yarn hanging rod 2, a screw rod 6 and a universal wheel 4. Several yarn hanging rods 2 are installed on the upper end of the base 1, and the yarn hanging rods 2 are evenly arranged. The cloth is placed on the upper end of the base 1, and the base 1 is provided with an air duct. The bottom end of each yarn hanging rod 2 is connected to the air duct. The yarn hanging rod 2 is a hollow structure, and several ventilation holes 9 are evenly distributed on the surface of the yarn hanging rod 2. Four screw rods 6 are fixedly installed on the upper end of the base 1, at least four universal wheels 4 are installed on the lower end of the base 1, and air inlets 3 are arranged on both sides of the base 1, and the air inlets 3 are connected with the air duct.

[0019] In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com