Hollow ball filled airtight spherical explosion-proof container

A hollow ball and spherical technology, applied in the field of hollow ball filled airtight spherical explosion-proof containers, can solve the problems of inconvenient installation and transportation, secondary damage, high cost, etc., and achieve the effects of eliminating threats, reducing weight, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

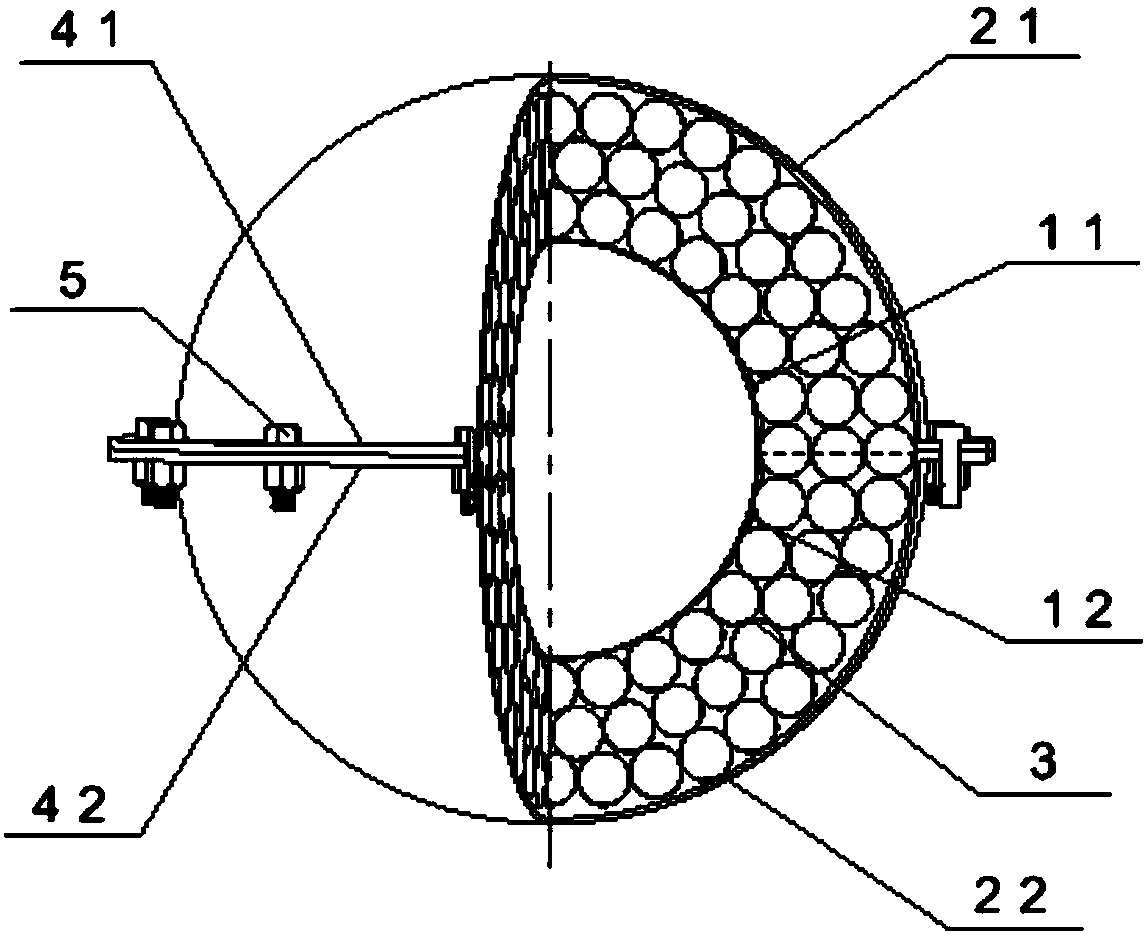

[0022] The airtight spherical explosion-proof container filled with hollow spheres of the present invention comprises two symmetrical hemispheres, and the two hemispheres are fixed to form a spherical shape with a closed space. The hemisphere is composed of an inner panel, a filled hollow sphere layer 3, an outer panel and a flange fixing the outer panel. The flange fixing the outer panel has a number of evenly distributed bolt holes in the circumferential direction. Specifically, such as figure 1 As shown, the upper sphere is made of upper sphere inner panel 11, upper sphere outer panel 21, filled hollow sphere layer 3 and upper sphere flange 41 fixing upper sphere outer panel 21, and the lower sphere is composed of lower sphere inner panel 12, lower sphere outer panel Panel 22, filled holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com