Moving sieve fault diagnosis method based on Weibull analysis model

A fault diagnosis and analysis model technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as high complexity, large environmental impact, long coal preparation production and processing cycle, etc., to overcome The effect of long cycle and reduction of economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

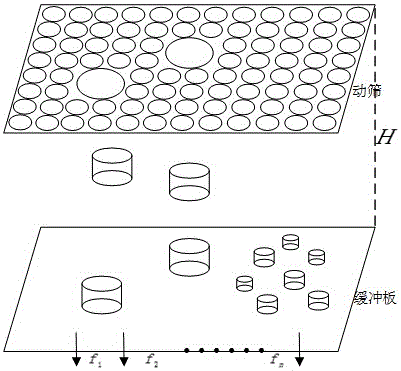

[0039] A dynamic sieve fault diagnosis method based on a Weibull analysis model, characterized in that: the dynamic sieve fault diagnosis method uses an impact force sensor to collect the impact force of a coal block falling from a driven sieve plate on a buffer plate, and calculates that the dynamic sieve plate is normal. The proportion range of the amount of coal passing through the moving sieve plate in the total sample, that is, the particle size distribution range of the coal; analyze the falling process of the coal within the time period t, and calculate according to the total impact force P collected by the impact force sensor Compare the proportion of the total amount of falling coal lumps on the moving sieve plate to the total sample within the time period t with the proportion range when the moving sieve plate is normal, so as to measure the total amount of falling coal blocks and diagnose the fault of the moving sieve:

[0040] Assuming that the aperture diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com