Preparation method of TODI base polyurethane micropore elastomer

A technology of microcellular elastomer and polyurethane, which is applied in the field of preparation of polyurethane microcellular elastomer, can solve the problems of large dynamic fatigue deformation and poor heat resistance, and achieve the effect of overcoming large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

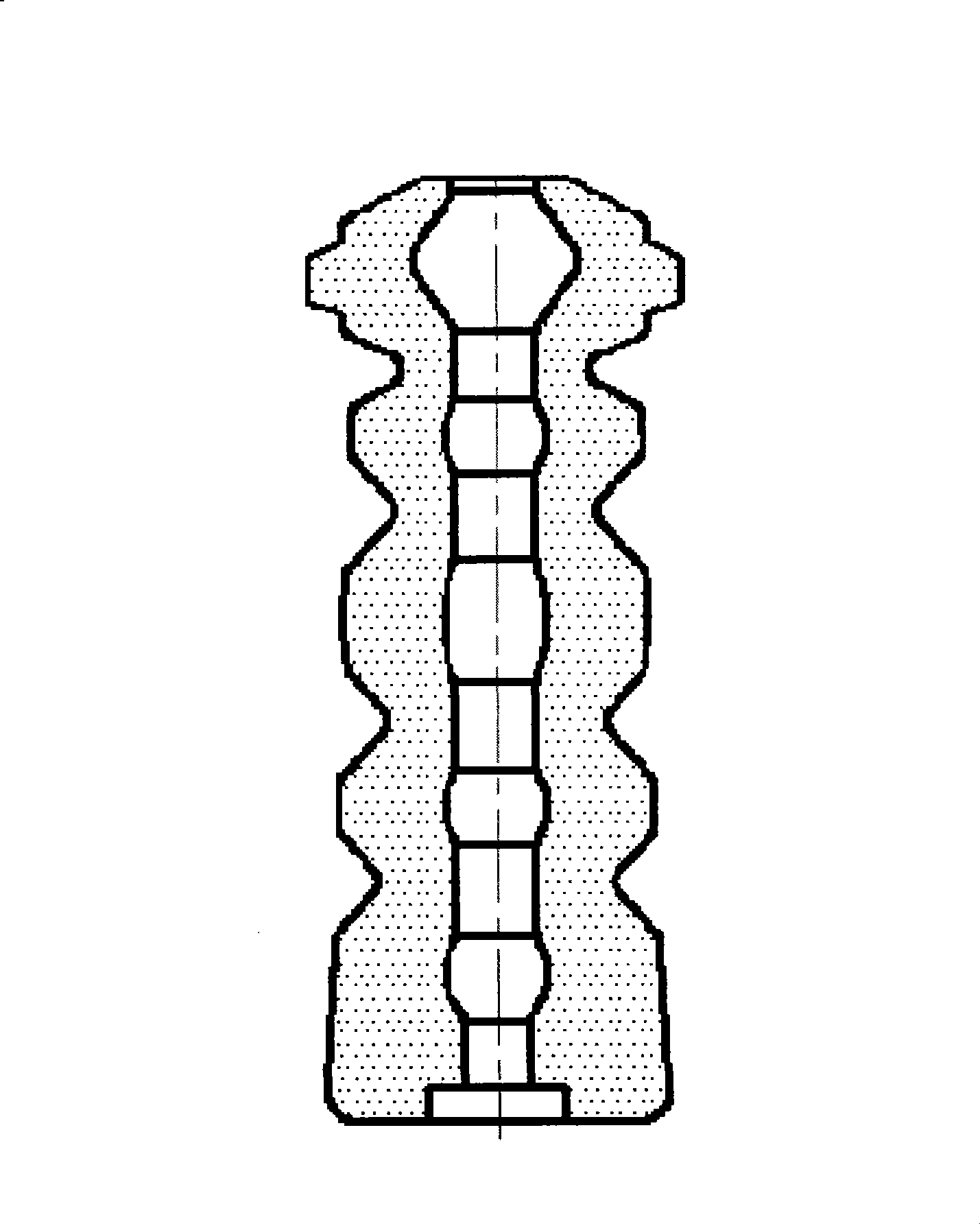

Image

Examples

Embodiment 1

[0028] Polyadipate with a molecular weight of 2000 reacts with TODI at 70-110°C to obtain a prepolymer with an NCO content of 6.2%. The main extender is polyadipate, and the foaming agent, catalyst, surface Active agent accounted for 3% of the total.

[0029] Using a low-pressure foaming machine, mix the prepolymer and the expansion agent according to the ratio of the isocyanate index to 100%, inject the reaction material liquid into the mold at 110°C, demould after 30 minutes, and post-cure at 110°C for 24hrs.

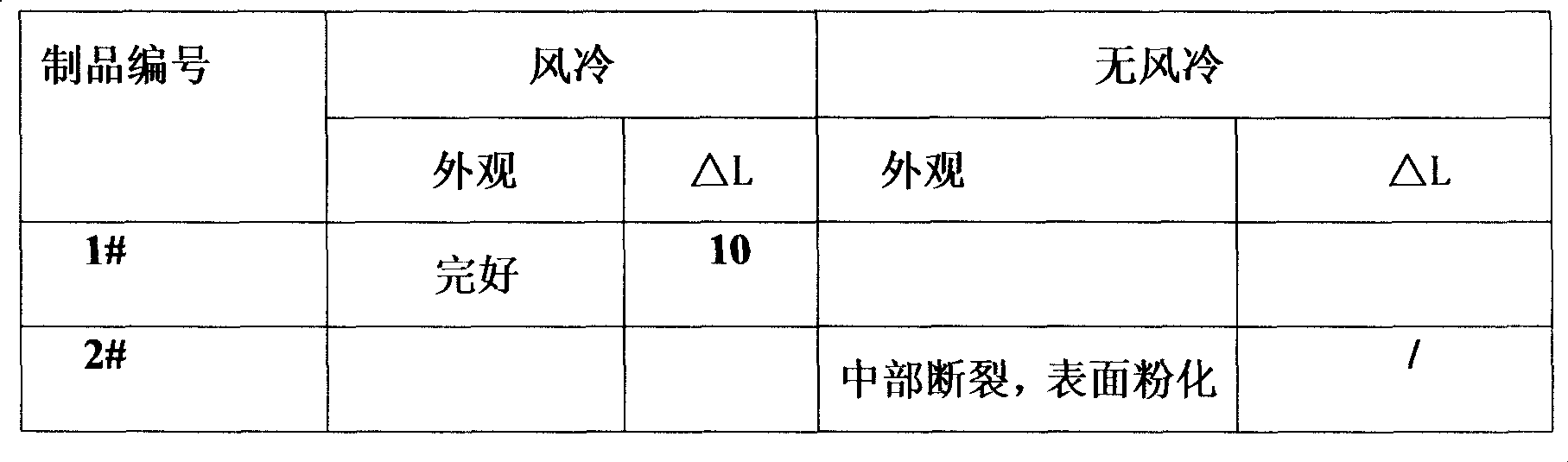

[0030] The above molded products have been subjected to 400,000 times of dynamic fatigue performance tests and the results are as follows:

[0031]

Embodiment 2

[0038] Polyadipate with a molecular weight of 2000 reacts with TODI at 70-110°C to obtain a prepolymer with an NCO content of 6.2%. The main extender is polyadipate, and the foaming agent, catalyst, surface Active agent accounted for 3% of the total.

[0039] Using a low-pressure foaming machine, mix the prepolymer and the expansion agent according to the ratio of the isocyanate index to 100%, inject the reaction material liquid into the mold at 110°C, demould after 30 minutes, and post-cure at 110°C for 24hrs.

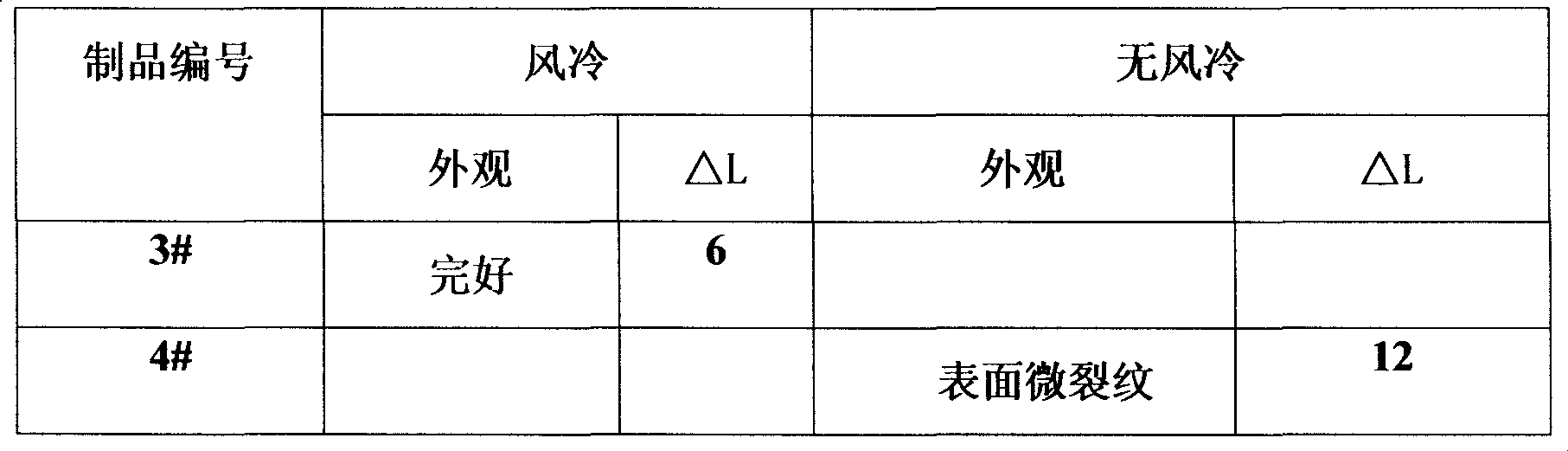

[0040] The dynamic fatigue performance test results of the above molded products are as follows:

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com