Capillary Viscometer and Method for Measuring Fluid Viscosity

A technology of viscosity measurement and capillary tube, which is applied in the direction of direct current flow characteristic measurement, etc., can solve the problems of sample physical property change, sample waste, and can no longer be reused, so as to achieve the effect of improving utilization rate, high measurement efficiency and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

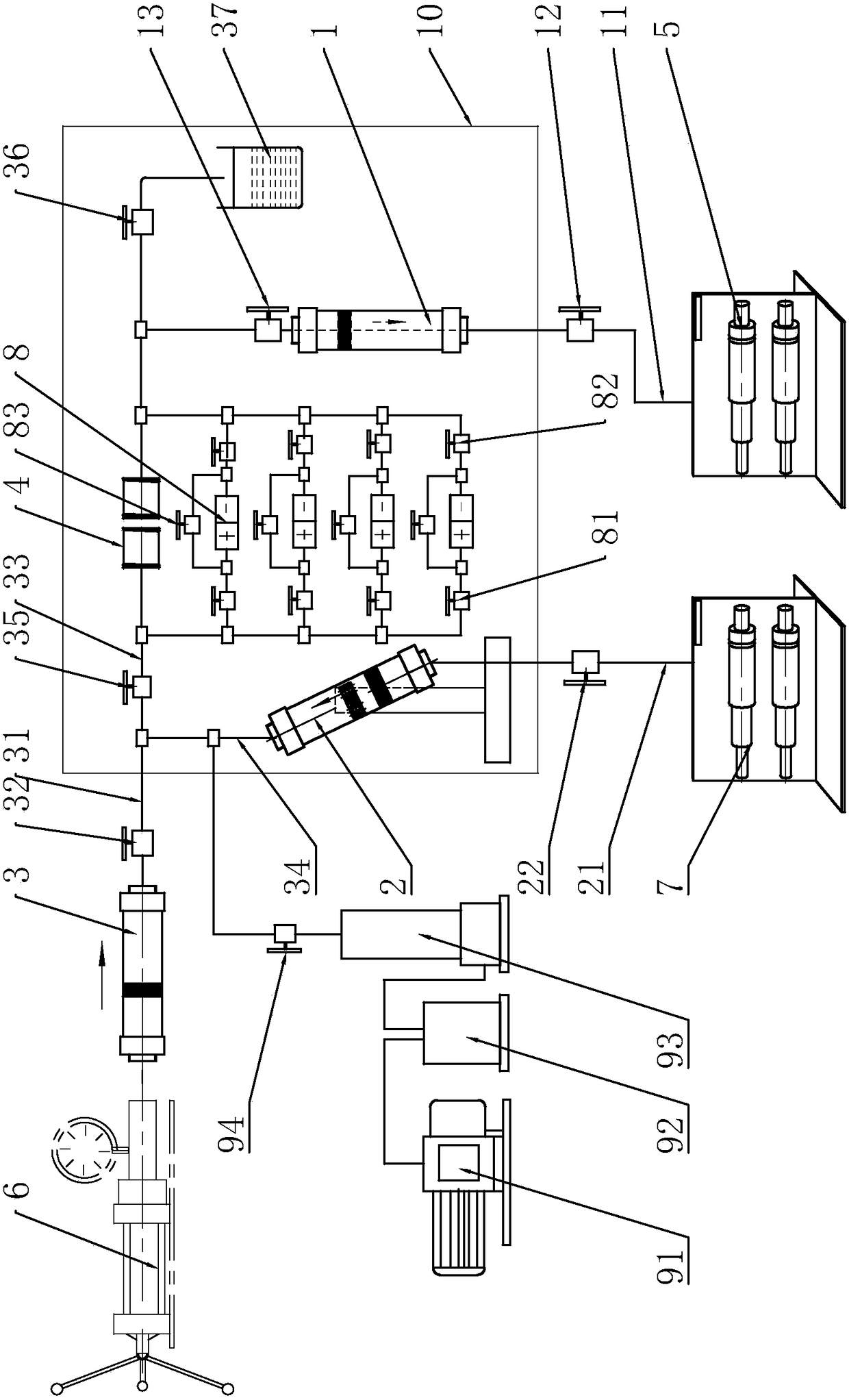

[0028] Such as figure 1 As shown, the capillary viscometer of the present invention comprises a piston container 1, a sample dispenser 2, a sample storage container 3, a capillary 4, a differential pressure measurement module, a vacuum device, and the outlet of the pressure tracking pump 5 is connected to the piston container through the first pipeline 11. 1, the first valve 12 is connected in series on the first pipeline 11, and the second valve 13 is installed at the outlet of the piston container 1.

[0029] The outlet of the manual pump 6 is communicated with the sample storage container 3 through the pipeline, and the outlet of the sample storage container 3 is connected with the sampling pipeline 31, and the sampling valve 32 is connected in series on the sampling pipeline 31, and the sampling pipeline 31 passes through the first branch respectively. The pipeline 33 and the second branch pipeline 34 are connected with the capillary 4 and the sample dispenser 2, the fourt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com