High-voltage electric appliance test loop trigger system and method applying pulse transformer technology

A technology of pulse transformers and high-voltage electrical appliances, which is applied to the components of electrical measuring instruments, instruments, and measuring electronics. It can solve the problems of insufficient withstand voltage of the trigger system, large dispersion of penetration time, and failure to successfully penetrate, etc., to achieve overall dispersion. Small size, improved test control accuracy, structural form and integrated effect of floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

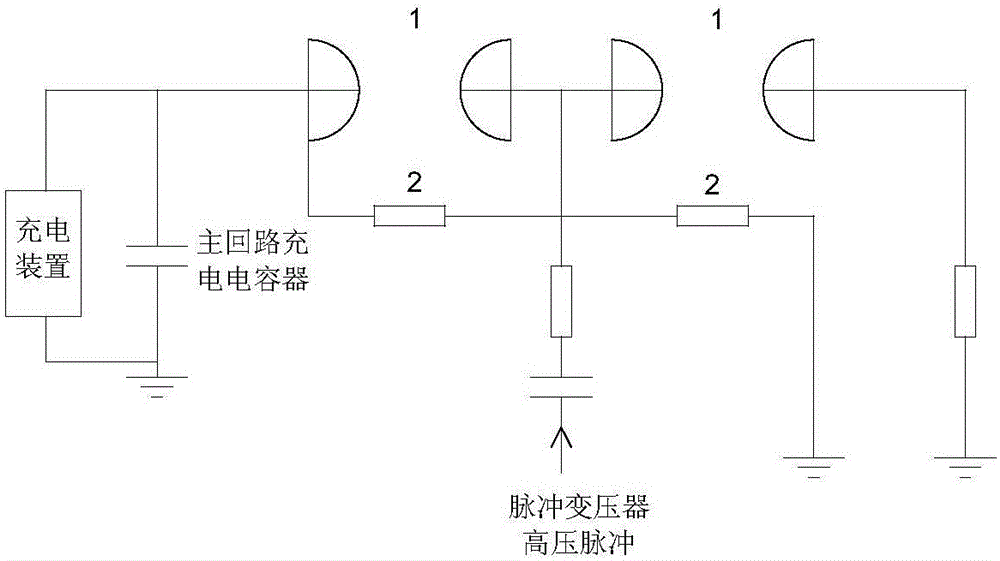

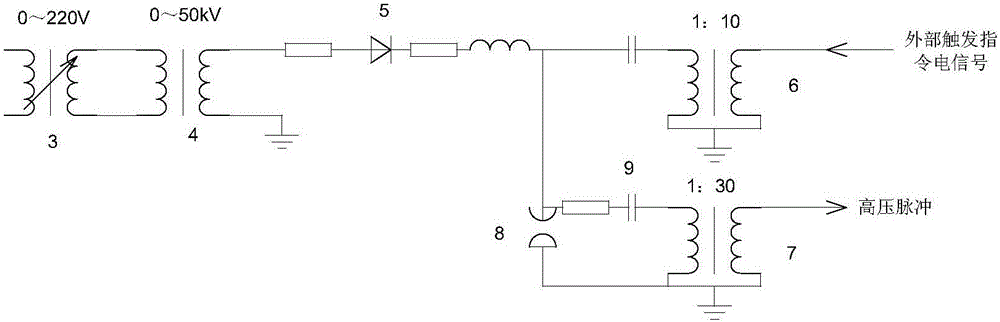

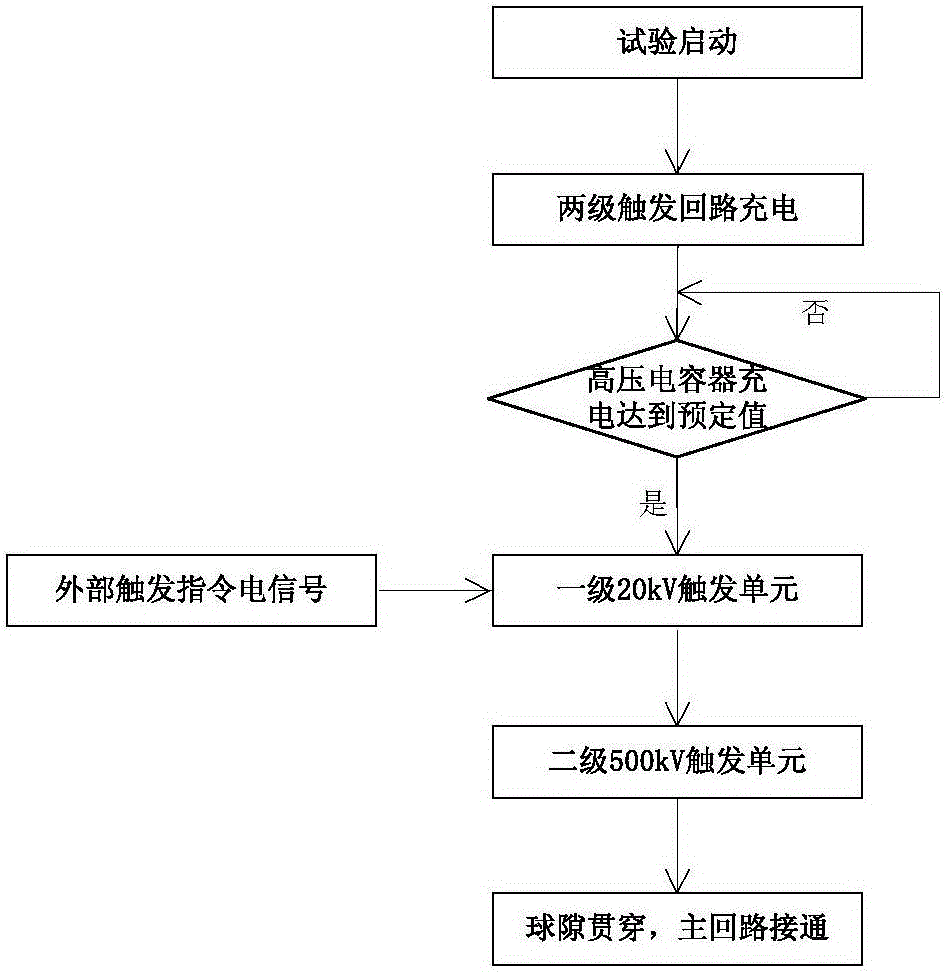

[0022] A kind of triggering system of the high-voltage electrical apparatus test loop using the pulse transformer technology of the present invention comprises an ignition device body and a two-stage triggering loop; figure 1 As shown, one end of the ignition device body is connected to the main circuit charging capacitor pre-charged by the charged device, and the other end is connected to the load. Two pairs of graphite ball gaps 1 are used in this preferred example; the ignition device body relies on two pairs of graphite ball gaps 1 to connect the main circuit during the test, and each pair of graphite ball gaps 1 includes two graphite hemispheres, and the gap distance between two pairs of graphite ball gaps 1 Almost the same, the voltage equalization is performed by the voltage equalizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com