A Fast Closing Gap Controlled by Transverse Magnetic Field and Its Application

A technology of transverse magnetic field and rapid closure, applied to spark gaps with auxiliary trigger devices, spark gaps, spark gap components, etc., can solve the problems of restricting the life of controllable gaps and complex electrode discharge mechanisms, and achieve simple structure and high performance Stable and high penetrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

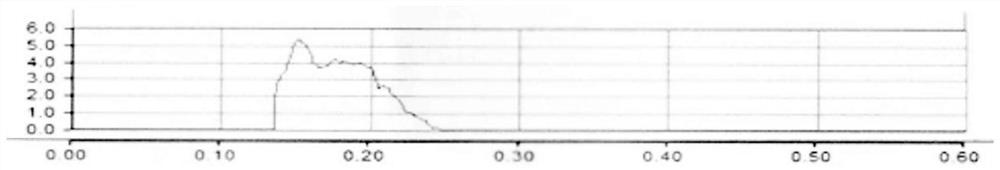

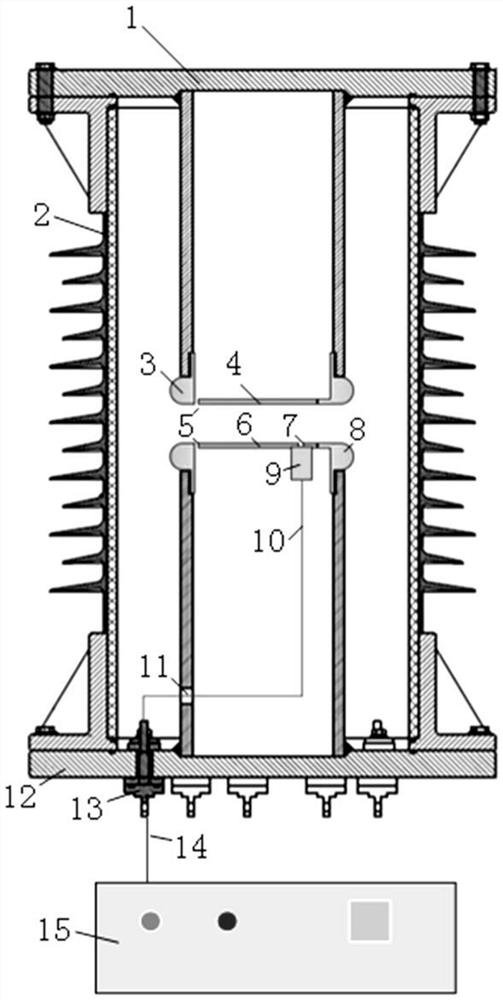

[0051] This embodiment is a fast closing gap controlled by a transverse magnetic field, and its overall structure is shown as figure 1 As shown; the plasma injector is embedded in the gap electrode, and connected to the control device through high-voltage wires and lead-out terminals.

[0052] The gap body consists of a pair of hollow metal tubes to set the gap electrodes and assemble them in the composite sleeve, which are high-voltage electrodes and low-voltage electrodes respectively; the gap main electrode is embedded with a pair of first rectangular sub-electrodes 4 and second Rectangular sub-electrodes 6 .

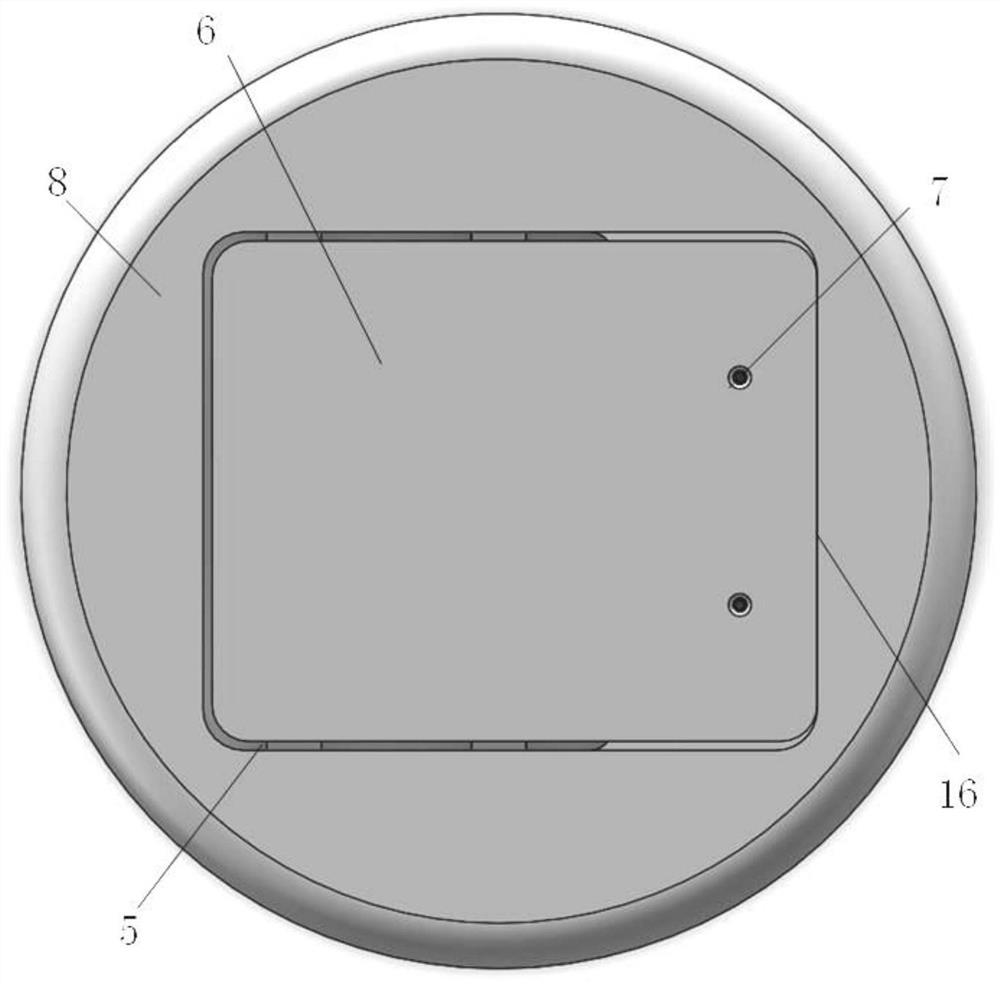

[0053] The length of the first rectangular sub-electrode 4 and the second rectangular sub-electrode 6 is 100mm, the width is 80mm, and the thickness is 6mm, and there is a connected short side closely connected with the gap main electrode, and the remaining three sides are not connected with the gap main electrode, The pitch is 1mm. The material of the first rectan...

Embodiment 2

[0058] This embodiment is a fast closing gap controlled by a transverse magnetic field, and its overall structure is shown as figure 1 shown. The plasma injector is embedded in the gap electrode, and is connected with the control device 15 through the high-voltage wire and the lead-out terminal 13 .

[0059] The gap body consists of a pair of hollow metal tubes to set the gap electrodes and assemble them in the composite sleeve, which are high-voltage electrodes 3 and low-voltage electrodes 8 respectively; the gap main electrode is embedded with a pair of first rectangular sub-electrodes 4 and The second rectangular sub-electrode 6 .

[0060] The length of the first rectangular sub-electrode 4 and the second rectangular sub-electrode 6 is 150mm, the width is 90mm, and the thickness is 10mm, and there is a connected short side 16 closely connected with the main electrode of the gap, and the remaining three sides are not connected with the main electrode of the gap , the spaci...

Embodiment 3

[0065] This embodiment is a fast closing gap controlled by a transverse magnetic field, and its overall structure is shown as figure 2 shown. The plasma jet 9 is embedded in the gap electrode, and is connected to the control device 14 through the high-voltage wire and the lead-out terminal 13 .

[0066] The gap body consists of a pair of hollow metal tubes to set the gap electrodes and assemble them in the composite casing, which are the high-voltage electrode 3 and the low-voltage electrode 8 respectively. The gap main electrode is embedded with a pair of first rectangular sub-electrode 4 and second rectangular sub-electrode 6 that can generate a transverse magnetic field to drive arc movement.

[0067] The length of the first rectangular sub-electrode 4 and the second rectangular sub-electrode 6 is 160mm, the width is 120mm, and the thickness is 12mm, and there is a connected short side closely connected with the gap main electrode, and the remaining three sides are not co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com