High-voltage electrical apparatus test triggering system and method applying plasma injection technology

A technology of high-voltage electrical appliances and plasma, applied in the direction of testing dielectric strength, etc., can solve problems such as premature penetration and failure to penetrate successfully, and achieve the effect of eliminating potential safety hazards, saving test time, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

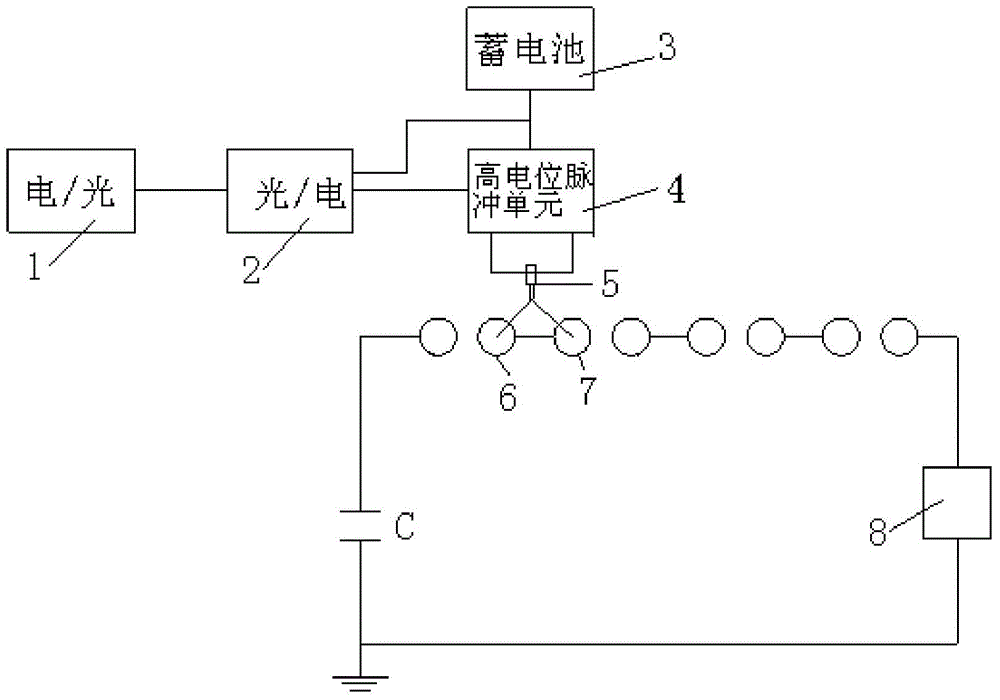

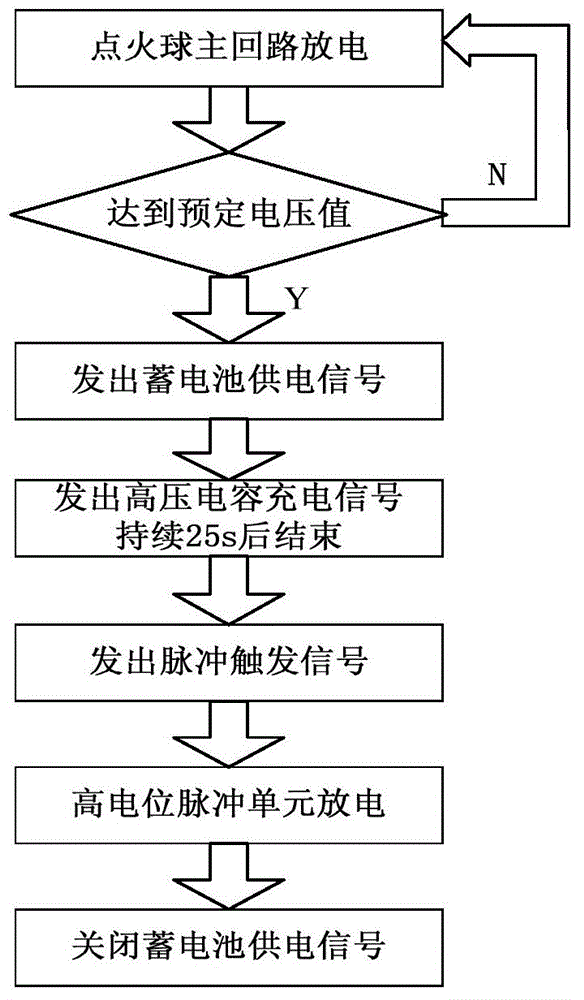

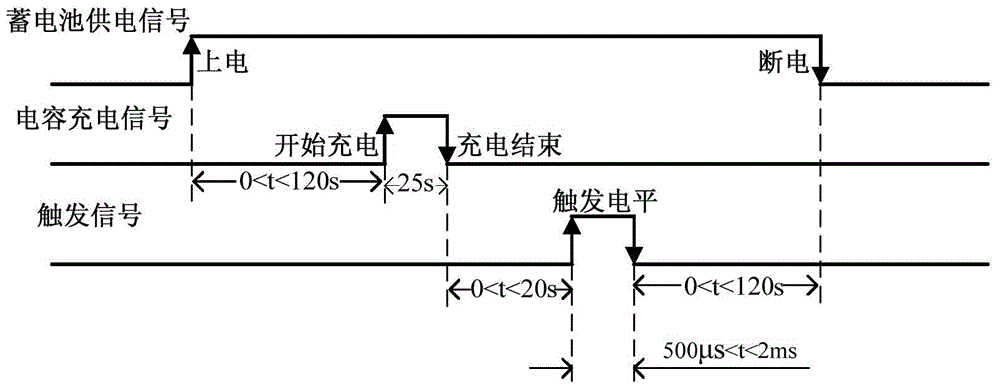

[0023] see Figure 1 to Figure 3 As shown, the present invention is a high-voltage electrical test trigger system using plasma jet technology, including an electro-optical converter 1, a photoelectric converter 2, a storage battery 3 and a high-potential pulse unit 4.

[0024] The electro-optic converter 1 includes a battery power supply signal input end, a high-voltage capacitor charging signal input end, a trigger electrical signal input end, a battery optical signal output end, a high-voltage capacitor charging optical signal output end, and a trigger optical signal output end; the photoelectric converter 2 includes a battery Optical signal input end, high voltage capacitor charging optical signal input end, trigger optical signal input end, battery power supply signal output end, high voltage capacitor charging signal output end and trigger electrical signal output end.

[0025] The battery light signal output terminal, the high-voltage capacitor charging light signal outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com