High-precision sub-pixel extraction method for centers of light bars of structured light

A light strip center and extraction method technology, applied in the field of image processing, can solve the problems of low precision, difficulty in accurately extracting the light strip center position, uneven thickness of the light strip, etc., and achieves the effect of high extraction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0059] like Figure 1-6 shown.

[0060] In the embodiment of the present invention, a light fringe image is obtained by taking a camera, the image acquisition camera is a Daheng CCD camera F-504B / C, the resolution is 2452*2056, and the lens is a Daheng Computar fixed focus lens M0814-MP2, with a focal length of 8mm , The laser stripes are produced by a Powell laser 3D scanner, the output wavelength is 650nm, the output power is adjustable, and the maximum output power is 100mW.

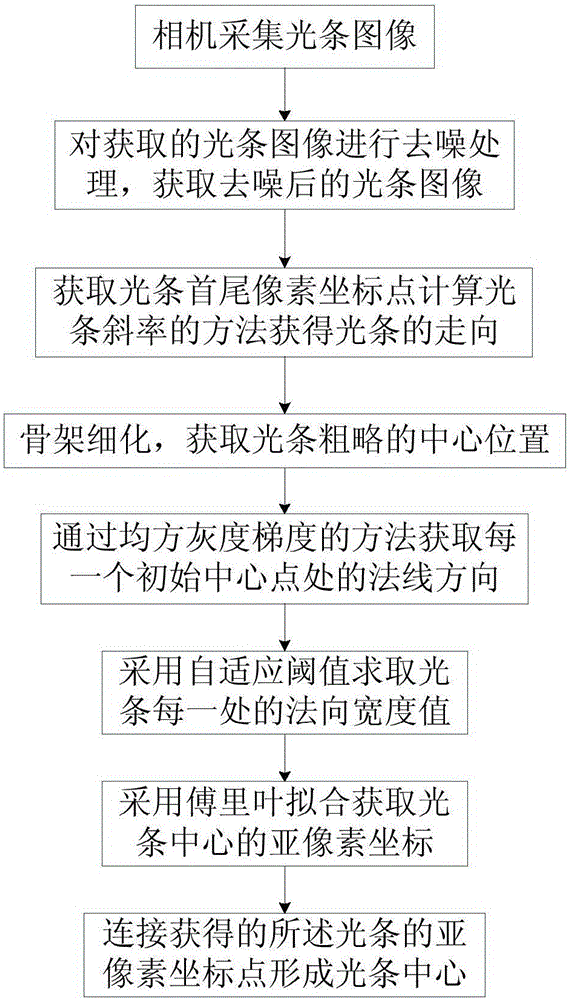

[0061] The process of a high-precision sub-pixel extraction method for the center of a structured light strip is as follows figure 1 shown, it includes the following steps:

[0062] Step 1: Perform denoising processing on the acquired light stripe image to obtain the denoised light stripe image, which includes the following sub-steps:

[0063] Step 1.1: Remove the non-random...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com