GaN Growth Method Based on Black Phosphorus and Magnetron Sputtering AlN

A magnetron sputtering and aluminum nitride technology, applied in the field of electronics, can solve the problems of limiting the selection range of substrates, large thermal expansion coefficient, affecting the quality of GaN materials, etc., and achieve the effect of reducing the number of common dislocation defects and improving the quality of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

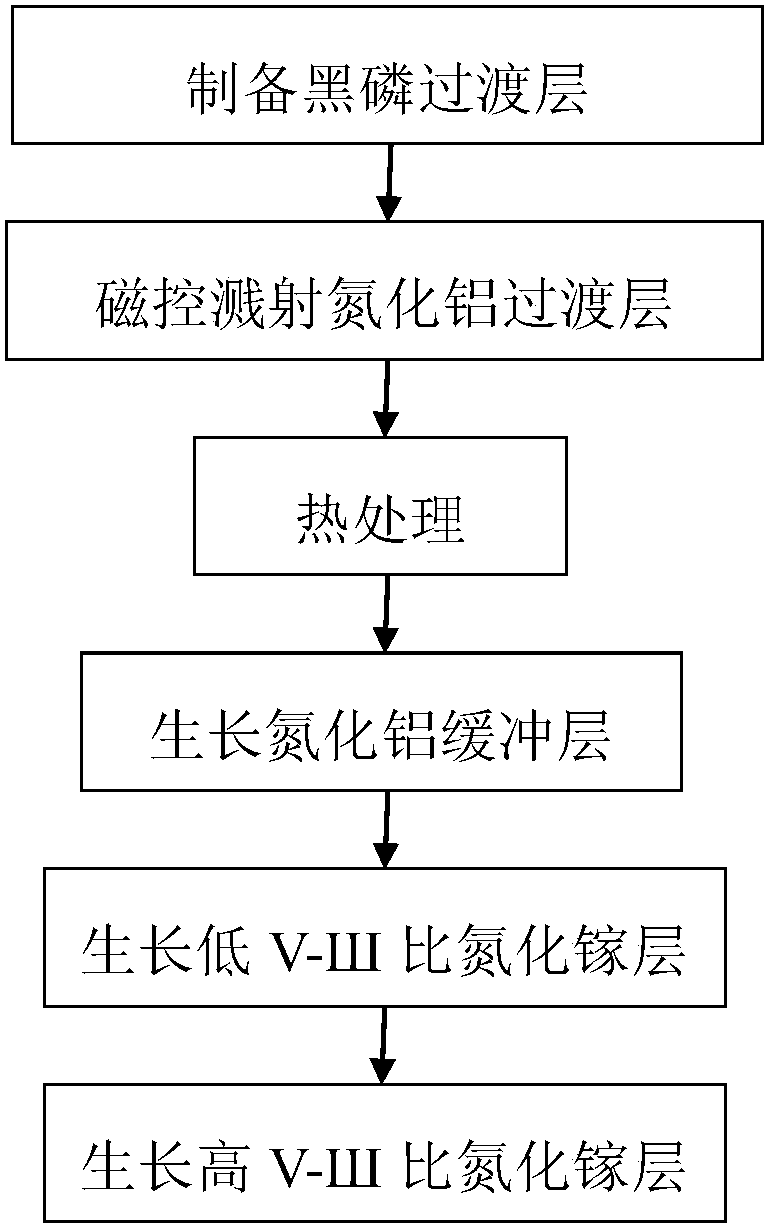

Method used

Image

Examples

Embodiment 1

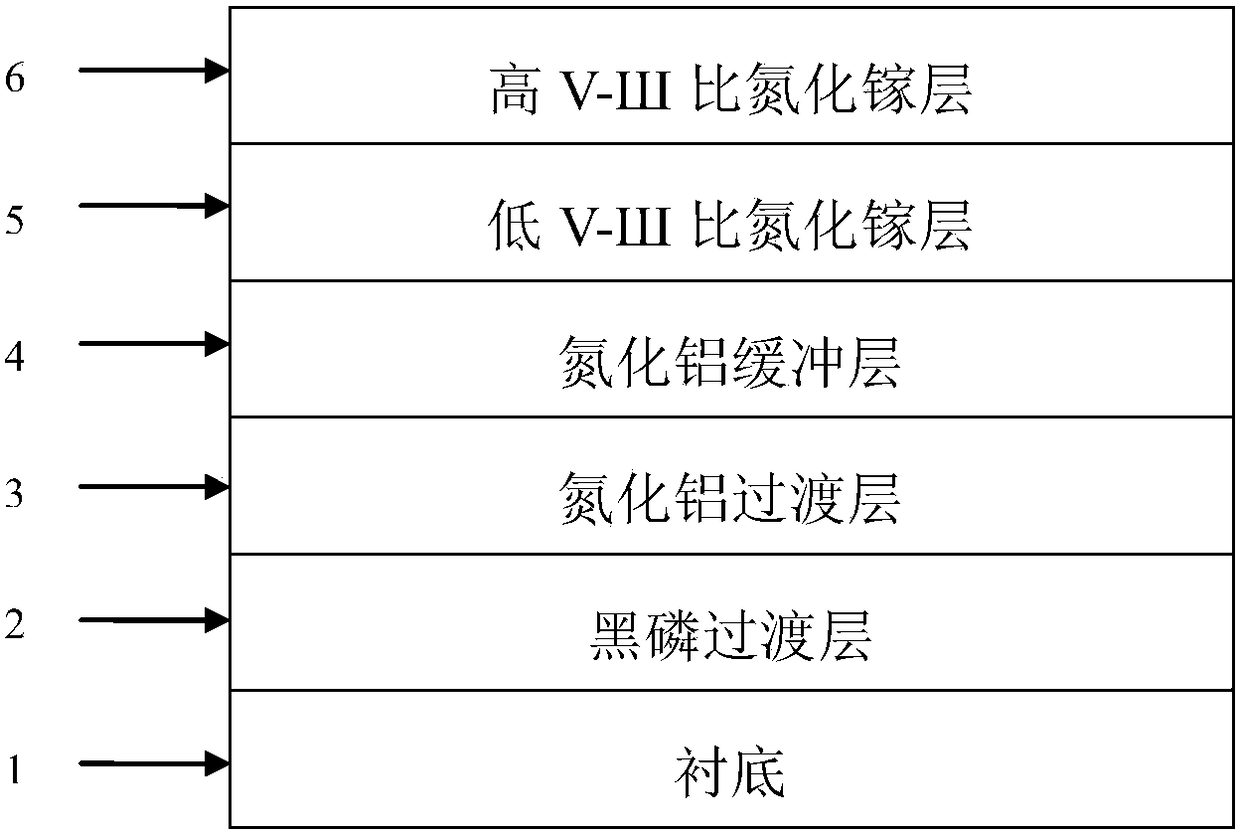

[0051] Embodiment 1: Ga-surface gallium nitride film based on black phosphorus and magnetron sputtering aluminum nitride.

[0052] Step 1. Prepare black phosphorus transition layer.

[0053] The silicon substrate was pretreated with acetone and deionized water and dried. Red phosphorus with a purity of 99.9% was put into a cube-shaped ultra-high pressure device, and the constant pressure in the cube-shaped ultra-high pressure device was set to 10 kbar. Keep the pressure of the cube-type ultra-high pressure device constant, heat the cube-type ultra-high pressure device to 1000°C, then cool down the temperature in the cube-type ultra-high pressure device by 100°C every hour until the temperature in the cube-type ultra-high pressure device reaches 600°C, close the cube Type ultra-high pressure device, wait for the temperature and pressure in the cube-type ultra-high pressure device to room temperature and normal pressure, take out the synthesized black phosphorus crystal, the pu...

Embodiment 2

[0065] Embodiment 2: N-face gallium nitride film based on black phosphorus and magnetron sputtering aluminum nitride.

[0066] Step A. Preparation of black phosphorus transition layer.

[0067] The sapphire substrates were pretreated with acetone and deionized water and dried. Red phosphorus with a purity of 99.9% was put into a cube-shaped ultra-high pressure device, and the constant pressure in the cube-shaped ultra-high pressure device was set to 10 kbar. Keep the pressure of the cube-type ultra-high pressure device constant, heat the cube-type ultra-high pressure device to 1000°C, then cool down the temperature in the cube-type ultra-high pressure device by 100°C every hour until the temperature in the cube-type ultra-high pressure device reaches 600°C, close the cube Type ultra-high pressure device, wait for the temperature and pressure in the cube-type ultra-high pressure device to room temperature and normal pressure, take out the synthesized black phosphorus crystal, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com