A thermal management system for a power battery

A technology of thermal management system and power battery, applied in the field of thermal management system, can solve the problems of increasing battery weight, leaking battery, battery short circuit, etc., and achieve the effect of avoiding continuous work, low battery weight, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

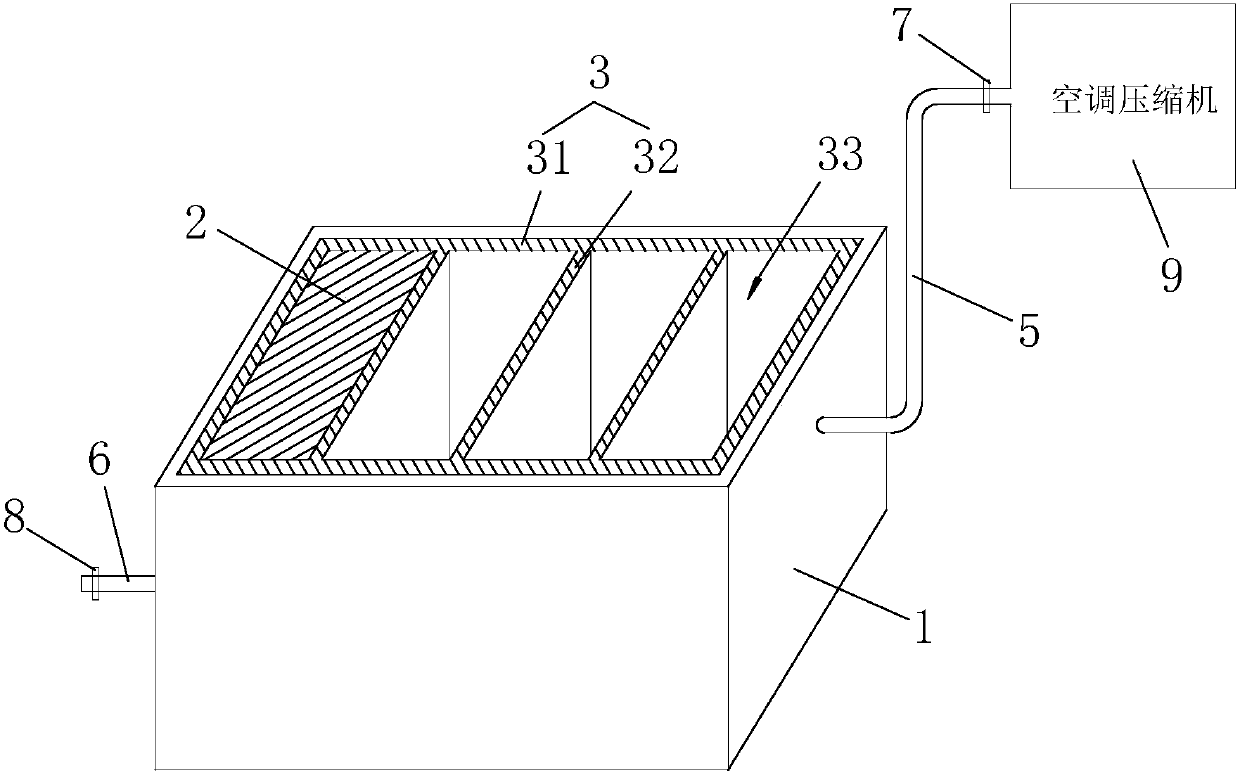

Embodiment 1

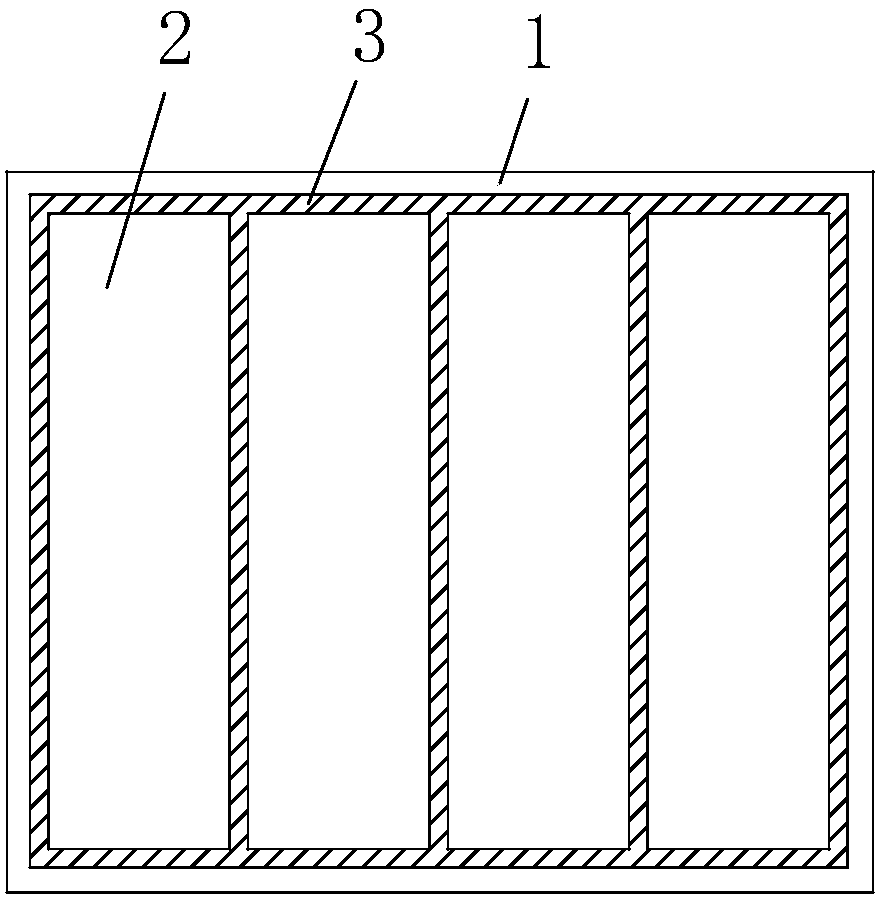

[0027] Such as image 3 As shown, the battery modules 2 are arranged in a row and multiple columns in the battery box 1 . That is, correspondingly, the number of small cavities 33 in the airbag 3 should be the same as the number of battery modules 2 , and the small cavities 33 are also correspondingly arranged in a row and multiple columns.

Embodiment 2

[0029] Such as Figure 4 As shown, the battery modules 2 are arranged in multiple rows and multiple columns in the battery box 1 . That is, on the basis of Embodiment 1, a partition is added in the middle, so that the small cavities 33 are arranged in multiple rows and multiple columns.

[0030] Working process of the present invention is as follows:

[0031] When in use, the airbag is arranged inside the battery box, and then the battery module is arranged in the small cavity of the airbag.

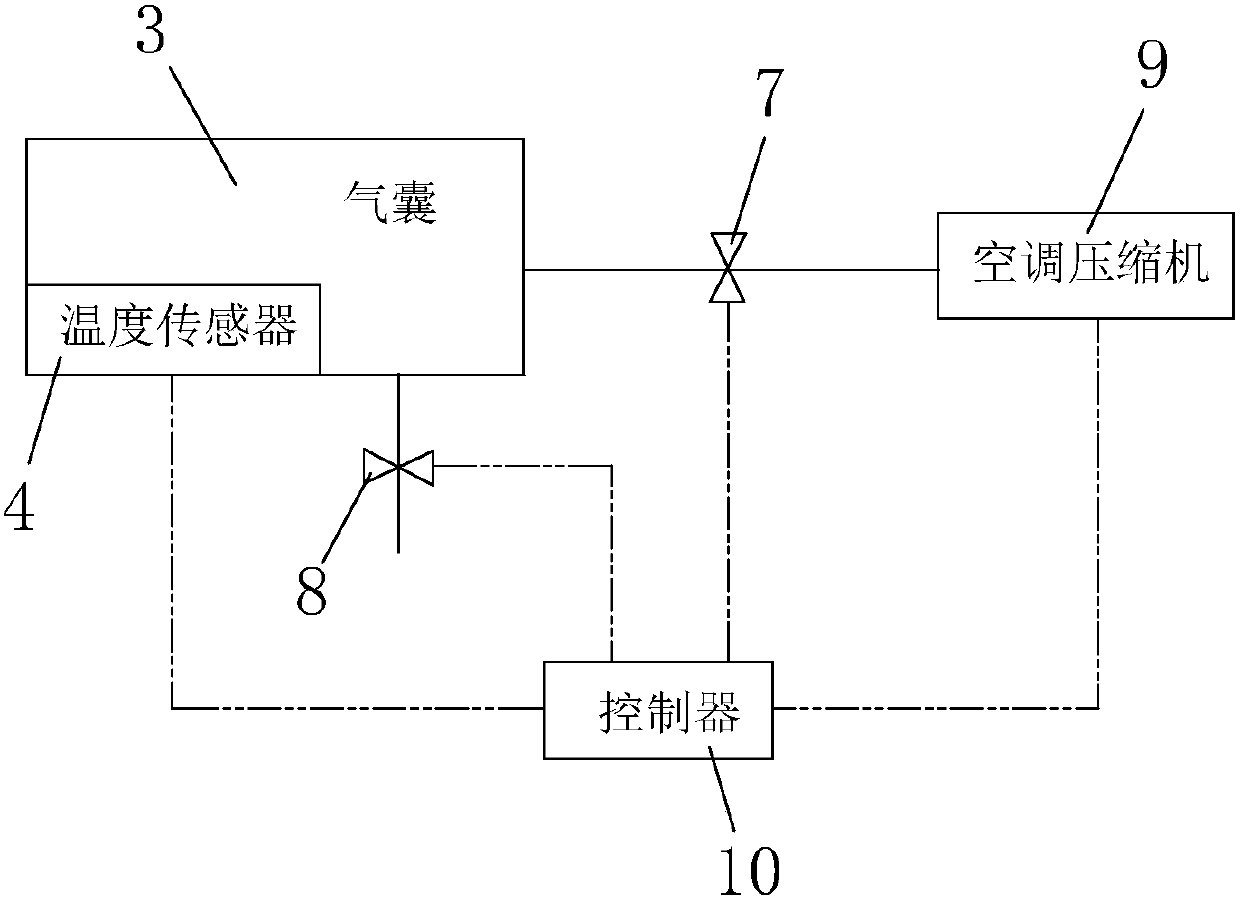

[0032] When the controller receives the temperature sensor signal and needs to be cooled, the controller controls the air conditioner compressor to turn on to the cooling state, and at the same time opens the first control valve on the intake pipe and closes the second control valve on the exhaust pipe. At this time, the air conditioner compressor The machine blows cold air into the airbag, and the airbag inflates and completely contacts the battery module, thereby cooling the battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com