Method for preparing safe and nutritional soybean milk

A production method and nutritional technology, applied in dairy products, milk replacers, applications, etc., can solve problems affecting protein digestion and utilization, allergic reactions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0022] A safe and nutritious soybean milk production method provides a motor, a crushing cutter, a heating device and a cup body, and at least includes a crushing stage and a heating stage.

[0023] (1) Crushing stage: including the step that the motor drives the crushing tool to rotate and crush the material, and the step that the motor stops working;

[0024] (2) Heating stage: including the step of heating the liquid in the cup by the heating device, and the step of stopping the heating by the heating device.

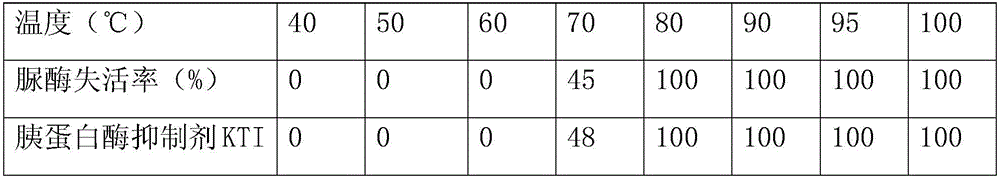

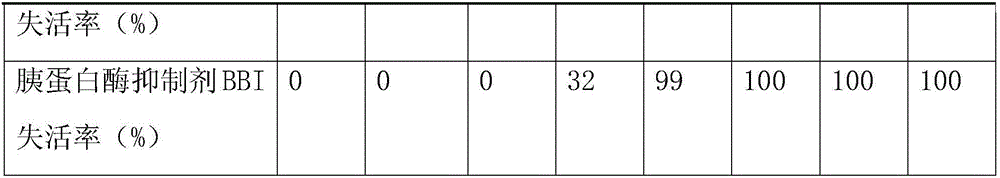

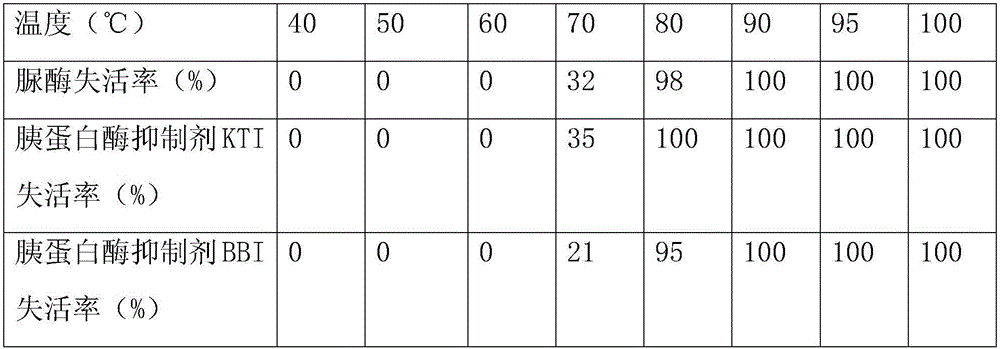

[0025] In the present embodiment, researches were carried out according to the timing of each pulverization stage, and the optimal heating time was obtained for the timing of each pulverization stage.

[0026] When the crushing stage is carried out when the liquid temperature is above 80°C, the optimum time for the heating device to heat the liquid in the cup after the temperature of the liquid in the cup is above 80°C is 6 to 15 minutes.

[0027] When the crushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com