Device for synthesising metal matrix powder material and high-flux synthesis method thereof

A powder material and metal-based technology, applied in the field of metal powder preparation, can solve the problems that hinder the development cycle of new materials and consume a lot of time, and achieve the effect of accelerating exploration and improving experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Example 1

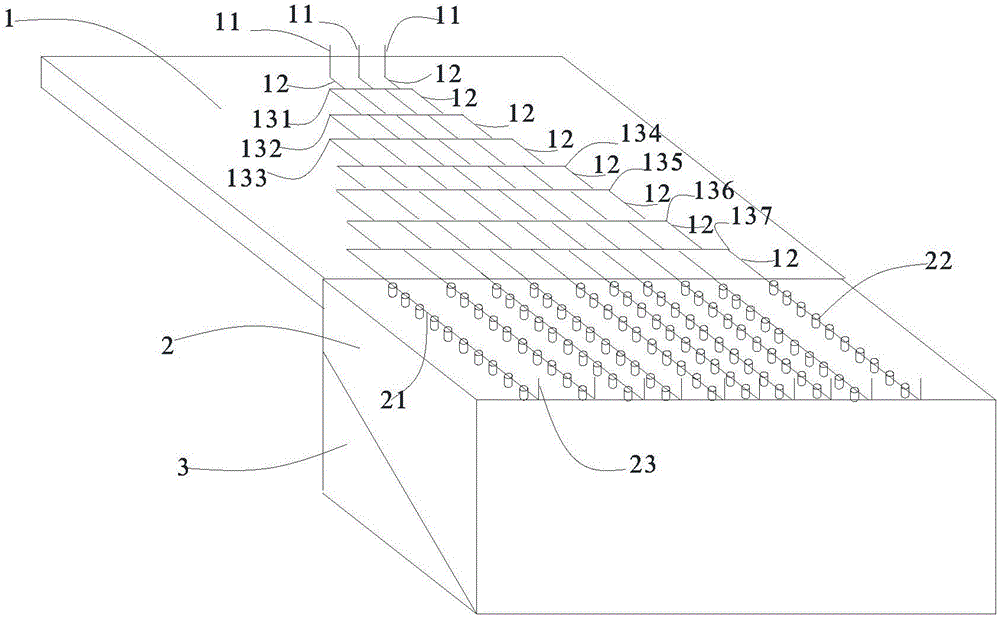

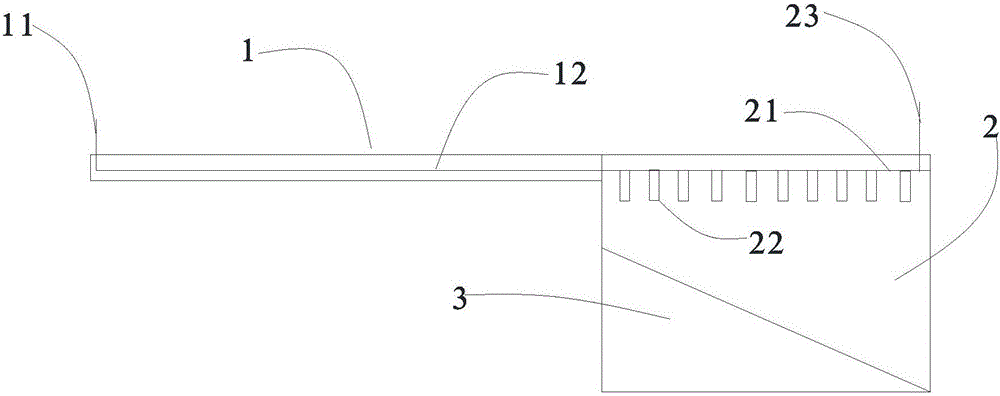

[0030] This embodiment relates to the preparation of a metal-based powder material, which specifically includes the following steps:

[0031] Add H at a concentration of 20mg / 50mL to the three inlets 2 PtCl 6 The solution is used as a metal precursor solution with a concentration of 5mg / mL NaBH 4 The solution acts as a reducing agent and deionized water acts as a solvent. The metal precursor solution, the reducing agent solution and the solvent are mixed into the reaction liquid through the horizontal flow channel, and then diffused to the liquid outlet and flowed into each reactor through the liquid flow channel in turn. Turn on the heater to make the output temperature of the heater 50 After reacting at ℃ for 24 hours, it was dried to obtain powder metallic platinum material in each reactor.

Example Embodiment

[0032] Example 2

[0033] This embodiment relates to the preparation of a metal-based powder material, which specifically includes the following steps:

[0034] Add Pt(acac) with a concentration of 0.05mM to the three liquid inlets 2 And 0.03mM Ir(acac)3 as the metal precursor solution, W(CO) with a concentration of 0.15mM 6 The solution is used as a reducing agent and contains a mixed solution of oleylamine and oleic acid (the volume ratio of oleylamine and oleic acid is 8:2) as a solvent. After mixing the metal precursor solution, reducing agent solution, and solvent through a horizontal flow channel to form a reaction liquid, it diffuses to the liquid outlet and flows into each reactor through the liquid flow channel in turn. Turn on the heater to make the heater output temperature After 4 hours of reaction at 280°C, it was dried to obtain platinum-iridium alloy powder materials in each reactor.

[0035] In summary, the present invention uses the repeated splitting and merging ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom length | aaaaa | aaaaa |

| Bottom length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com