Sunshade assembly and skylight structure provided with sunshade assembly

A technology for components and sunshades, applied in the direction of windows, vehicle parts, roofs, etc., can solve the problem of reducing the headspace of the vehicle, and achieve the effect of low noise level and constant operating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

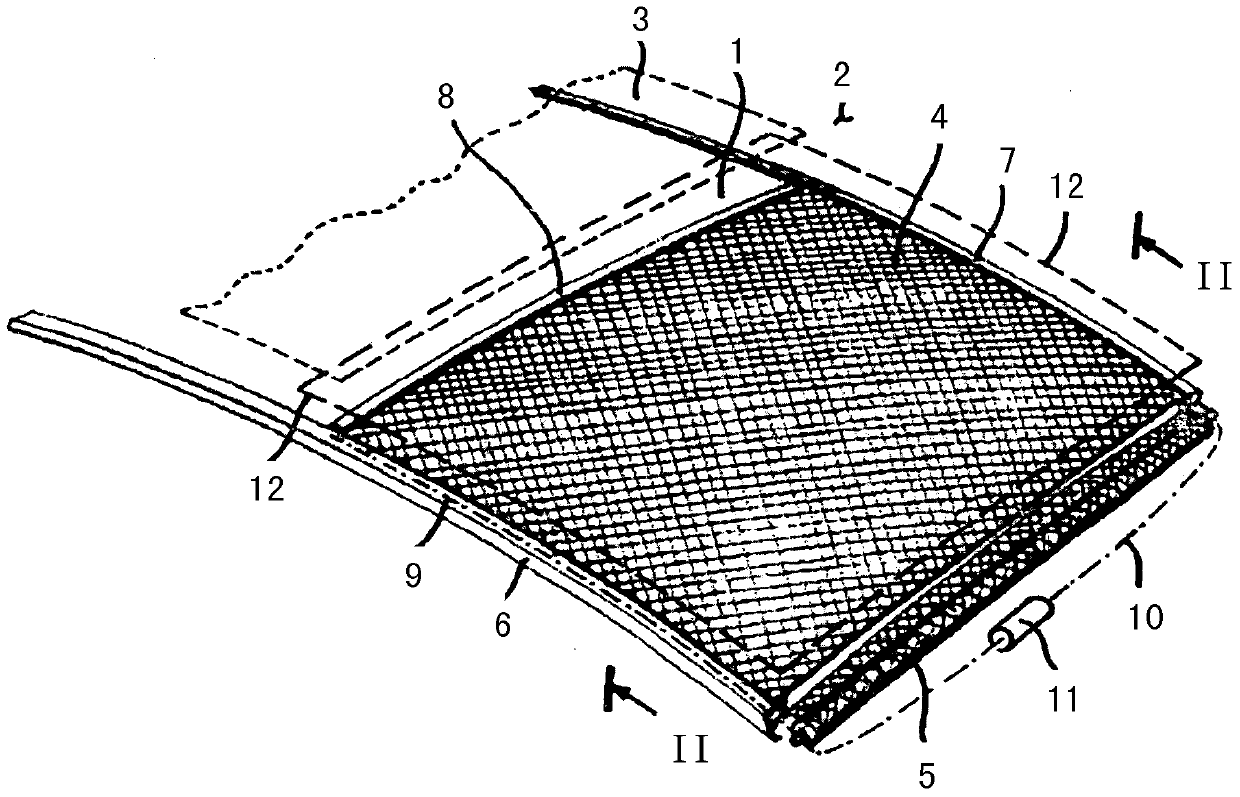

[0022] first reference figure 1 , shows an example of a sunroof structure for a vehicle, such as a passenger car, which has a roof assembly and may include a sunshade assembly according to the present invention. Said roof assembly is used to open and close at least one roof opening 1 in a stationary roof part 2 of a vehicle and comprises at least one movable closing part, in particular a rigid transparent panel 3 (not shown in detail). out, but known per se) can be moved in order to open and close said ceiling opening 1 . In general, it is known that the movable panels 3 are guided in longitudinal guides mounted on or formed in the stationary roof part 2 along the longitudinal sides 12 of the roof opening 1 . A user-operated device such as a motor or crank (not shown) is operatively coupled to the panel 3 by cables or the like for selectively moving the panel 3 between its open and closed positions. exist figure 1 The closing panel 3 is shown in the position where it opens ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com